Quote:

Originally Posted by zstroken

Less angle on u-joints is more good!

|

Just wanted to clear some things up. Less angle isn't 'more good' exactly. These are phased, u-jointed driveshafts, so they basically move forward and backwards over and over (it's kinda amazing the bearings in the u-joints and seals in the t-case last as long as they do!). If you don't match the angle of the t-case, you toss a TON of vibration and harshness into everything. It'll also pulse your output to your axle which isn't good for traction or axle shafts, or tire life for that matter.

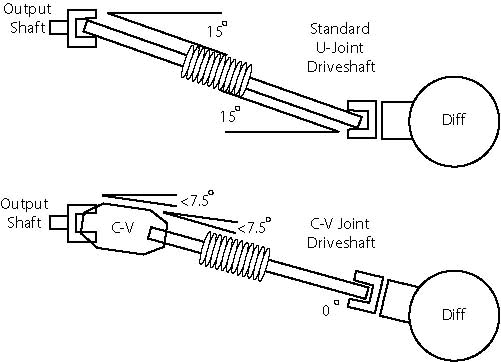

Check out this picture:

Ideally you want more than 2deg of angle (to keep the bearings/caps spinning and supplying grease), and less than 4deg of angle (to keep wear down in the bearings/caps).

On a double cardan setup, like in the front driveshaft, you want to match the driveshaft angle with that 2-4deg angle in mind (close to the 2deg if you can).

All that said, just measure your t-case angle, and then make some shims to match it on the pinion and you're good to go!

This is cool too: