Quote:

Originally Posted by Joesixpack

"

So using a "boxed tuner" on a factory ecu would be equivalent to being strapped down in a straight jacket.....

This pump at 250cc/second is a very good rate! With some quick math effectively moving close to both my pumps combined. |

Well no not really but it can be frustrating to use a ECU thatís has some limitations not able to fix it so you have to settle for a compromise on it. Thatís all.

Also having a look inside the control strategy can save you a lot of trail and error sometimes but after so many years playing with OEM ECU systems you know what is playing up most of the time.

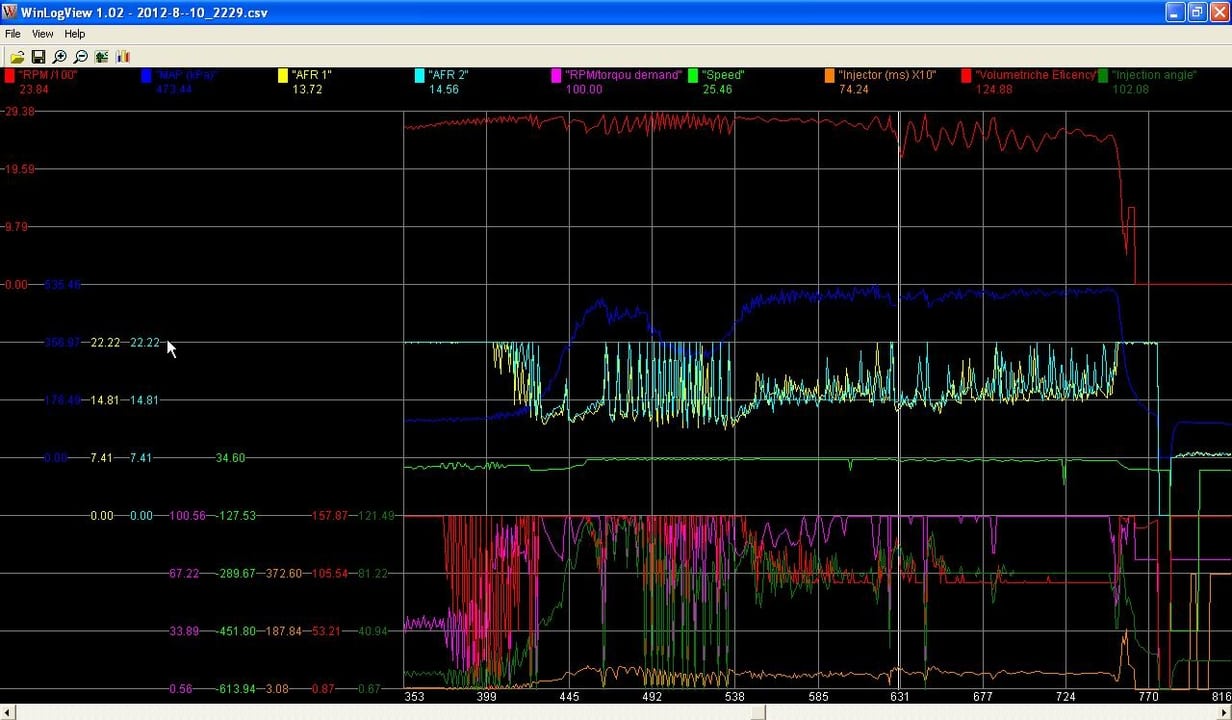

Here is an other example where the ECU has a load to do the keep the engine from staling and over speeding and at the same time controlling the boost level.

The run from the data log. This is what you get if your last in the super final digging up the holes from the other contenders that did not make the FP. Better not try this with a pickup truck I think?

@ Joesixpack your still in need of these Iveco injectors?

The 250cc a minute hi pressure fuelpump can take up to 108Hp shaft power and itís from a 3700Hp rated V20 machine so I have the funny feeling there is a lot more fuel there to pump. Putting this on a Cummins ISB engine and you will not be able to crank it. We used this on a 92 series V12 Detroit 2 stroke engine that we converted into commonrail and it pulled a 25Kw starter down when making 1000Bar to test the commonrail system.