You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

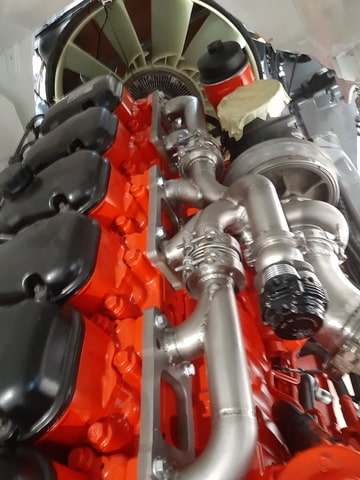

New engine build Scania DC1601 for our semi truckpuller.

- Thread starter tall boy

- Start date

Is that a single scroll turbine housing/manifold? If so why is it better than a twin scroll? I like how the exhaust manifold flows! Perhaps in your application you are concerned about compressor surge like a twin scroll setup might be more prone to having with the same turbine flow as a single scroll?

Also is your manifold able to retain the heat as compared to a cast manifold for example?

I'm trying to decide between single and twin scroll manifold/turbine housing setups for my 1.9L tdi project and would greatly value your input on this.

Also is your manifold able to retain the heat as compared to a cast manifold for example?

I'm trying to decide between single and twin scroll manifold/turbine housing setups for my 1.9L tdi project and would greatly value your input on this.

Is that a single scroll turbine housing/manifold? If so why is it better than a twin scroll? I like how the exhaust manifold flows! Perhaps in your application you are concerned about compressor surge like a twin scroll setup might be more prone to having with the same turbine flow as a single scroll?

Also is your manifold able to retain the heat as compared to a cast manifold for example?

I'm trying to decide between single and twin scroll manifold/turbine housing setups for my 1.9L tdi project and would greatly value your input on this.

Well this is not a 1.9: TDI LOL. Main problem we went all stainless hi tem steel is we had so many problems with the exhaust manifold lasting only half a rally even if we run 750c centigrade so only option we know is the single scroll TiAl turbine housing. Spool-up is not a problem on these S472SX-E.

Project completed. D26E6 race engine break in test. Layout of this one about 1350Hp but slam on a bigger turbo and it will do 1500 no problem.

For those who wonder why are the charge pipes are not connected. Well back in 2016 I nearly killed my self twice testing the same engine application. 1e time it broke all both on the dyno drive shaft running low end power and second time a charge pipe came off with a load of boost on full power and as these engines are out of development and as the this dyno is nowhere close able to handle the power and the ECU software likes to build boost on part load better run it some time NA on the smoke limit giving the piston rings some time the set well on the lines.

[ame="http://www.youtube.com/watch?v=1Hd8wQSXyTM"]New build D26 E6 A engine testing ready for delivery into a race truck. - YouTube[/ame]

Really like the last generation AIM data loggers with the icons on the bottom of the screen able to inform the driver a lot better what is going on. Before we had only text bottom of the screen like NO GPS speed signal. Now the icon goes from red to yellow and green if GPS speed signal drops it will use gearbox speed and if this fails it will speed limit on engine RPM as well and the icon associated with it will chance collar. Same goes for oil pressure and engine temp.

[ame="http://www.youtube.com/watch?v=eyO-0jR4yjU"]D26 E6 A race engine in combination with AIM MXG datalogger - YouTube[/ame]

For those who wonder why are the charge pipes are not connected. Well back in 2016 I nearly killed my self twice testing the same engine application. 1e time it broke all both on the dyno drive shaft running low end power and second time a charge pipe came off with a load of boost on full power and as these engines are out of development and as the this dyno is nowhere close able to handle the power and the ECU software likes to build boost on part load better run it some time NA on the smoke limit giving the piston rings some time the set well on the lines.

[ame="http://www.youtube.com/watch?v=1Hd8wQSXyTM"]New build D26 E6 A engine testing ready for delivery into a race truck. - YouTube[/ame]

Really like the last generation AIM data loggers with the icons on the bottom of the screen able to inform the driver a lot better what is going on. Before we had only text bottom of the screen like NO GPS speed signal. Now the icon goes from red to yellow and green if GPS speed signal drops it will use gearbox speed and if this fails it will speed limit on engine RPM as well and the icon associated with it will chance collar. Same goes for oil pressure and engine temp.

[ame="http://www.youtube.com/watch?v=eyO-0jR4yjU"]D26 E6 A race engine in combination with AIM MXG datalogger - YouTube[/ame]

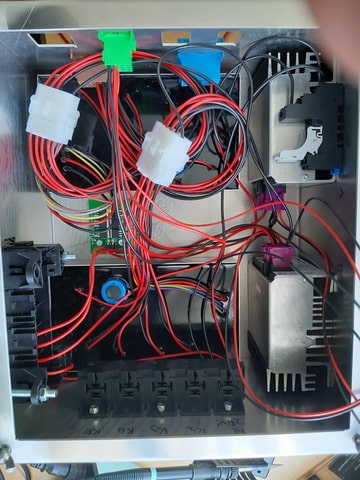

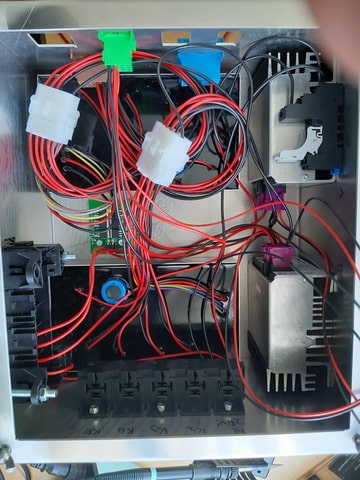

ECU or ECM and PDU (power distribution unit) all in one box.

Little time to post something, but also know that a lot of us unwittingly have all the time and therefore think of each other and help each other and take care of each other.

Motorsport teams worldwide. They continue to work in view of there orders for engine management systems ecushop mostly truck race and rally & pulling and in the USA and Canada the CAT C17 is the next thing, more engine revs due to a shorter stroke, but the bore size of the CAT C18 and we have the ECM to run these engines hard with engine speed trim pot and mutiple mappings including launch options.

Little time to post something, but also know that a lot of us unwittingly have all the time and therefore think of each other and help each other and take care of each other.

Motorsport teams worldwide. They continue to work in view of there orders for engine management systems ecushop mostly truck race and rally & pulling and in the USA and Canada the CAT C17 is the next thing, more engine revs due to a shorter stroke, but the bore size of the CAT C18 and we have the ECM to run these engines hard with engine speed trim pot and mutiple mappings including launch options.

With the virus ongoing all motor sport events are postponed till later date we all hope and motor sport teams extending development time on these project having time to do so we are on full load producing all kind of ECU & ECM. US & Canada seems to build C17 CAT a lot able to run the hi RPM with the C18 bore size combination and think you can order these as a kit as well.

Hart to tell what updates are done on the Dakar Speed Rally truck. Team is doing a load of shakedown on the truck and I done the first dialling the numbers in the ECU as we use the last generation 12.7L XPI Scania engine with second last generation fuel system with some of the stuff we developed last year and that in conjunction with the stainless steel exhaust manifold and TiAl Turbine housing and 6 speed Alison 4000 series AT makes it a interesting fast combination but as for the testing I did we did not have the longer final drive limiting top speed and gear step of way less than 400Rpm your only able to do top end RPM where your not using max torque and the TCM having a hard time keeping up with the engine hitting the rev limiter multiple times. So hope we have the Rally truck up to specification with the final drive and minimum weight as it should be as it’s under it class weight limit and yes that’s a good thing as the old one was more than 1500Kg to heavy so this alone will make this new truck a lot faster even if we drop some engine power.

Hart to tell what updates are done on the Dakar Speed Rally truck. Team is doing a load of shakedown on the truck and I done the first dialling the numbers in the ECU as we use the last generation 12.7L XPI Scania engine with second last generation fuel system with some of the stuff we developed last year and that in conjunction with the stainless steel exhaust manifold and TiAl Turbine housing and 6 speed Alison 4000 series AT makes it a interesting fast combination but as for the testing I did we did not have the longer final drive limiting top speed and gear step of way less than 400Rpm your only able to do top end RPM where your not using max torque and the TCM having a hard time keeping up with the engine hitting the rev limiter multiple times. So hope we have the Rally truck up to specification with the final drive and minimum weight as it should be as it’s under it class weight limit and yes that’s a good thing as the old one was more than 1500Kg to heavy so this alone will make this new truck a lot faster even if we drop some engine power.

Here he is: The DKR3 Rally Truck from Dakarspeed! Maurik van den Heuvel's new rally truck raises high expectations.

The proven chassis comes from the kitchen of the Czech Martin Macik (Big Shock Racing), the cabin is from America and is of the International brand. The heart of the truck is a 13 liter Scania engine and an Allison automatic gearbox is used.

Wereldprimeur! Eerste beelden van de Dakarspeed DKR3 in actie! - YouTube

The proven chassis comes from the kitchen of the Czech Martin Macik (Big Shock Racing), the cabin is from America and is of the International brand. The heart of the truck is a 13 liter Scania engine and an Allison automatic gearbox is used.

Wereldprimeur! Eerste beelden van de Dakarspeed DKR3 in actie! - YouTube

Not a lot of time to post things but working very hard on a new diesel engine management.

Was looking for a replacement for the diesel 1280DI ECU and I think I found it. This diesel ECU has a simple but effective fuel model that can be modified with a load of logical options and functions to chance the fuel model according to the needs of the project and in the near future we hope to get a power user option so we can write our own programming code for all different applications. After more than a decade programming diesel ECU systems I know what works well and with this ECU I can step thing up as we now got the option to communicate with canbus so it will be possible to communicate with the body controller of a vehicle and a semi truck they call them coordinator or VIC along with some other names so able to implement this ECU if needed in a more standard vehicle as well.

For now this ECU can run car solenoid injectors as I tested a load of them already and for truck engines we can use our more powerful injector drivers as these injector simply need more power to operate well. Also soon I hope to start testing pump injectors as well and in the near future we will see a load of updated coming as well. Stay tuned.

[ame="http://www.youtube.com/watch?v=jsTRs90yDvM"]Testing new diesel engine management - YouTube[/ame]

Was looking for a replacement for the diesel 1280DI ECU and I think I found it. This diesel ECU has a simple but effective fuel model that can be modified with a load of logical options and functions to chance the fuel model according to the needs of the project and in the near future we hope to get a power user option so we can write our own programming code for all different applications. After more than a decade programming diesel ECU systems I know what works well and with this ECU I can step thing up as we now got the option to communicate with canbus so it will be possible to communicate with the body controller of a vehicle and a semi truck they call them coordinator or VIC along with some other names so able to implement this ECU if needed in a more standard vehicle as well.

For now this ECU can run car solenoid injectors as I tested a load of them already and for truck engines we can use our more powerful injector drivers as these injector simply need more power to operate well. Also soon I hope to start testing pump injectors as well and in the near future we will see a load of updated coming as well. Stay tuned.

[ame="http://www.youtube.com/watch?v=jsTRs90yDvM"]Testing new diesel engine management - YouTube[/ame]

For those who are interested we start working together with Baldur's Control Systems for diesel ECU systems as I think it has great potential in it taking things forward as we share a lot of same ideas and solutions and after a decade trying different fuel models it’s not so hard to point in a direction where to find performance.

[ame="http://www.youtube.com/watch?v=22slwYgN5sY"]Baldurs Control Systems diesel ECU system - YouTube[/ame]

[ame="http://www.youtube.com/watch?v=22slwYgN5sY"]Baldurs Control Systems diesel ECU system - YouTube[/ame]

Just back from Autodrom Most in the Czech Republic where we spent two days testing with the Race Truck of Rennabteilung der Heinrich Hecker KG in the run-up to the European FIA Truck Race Championship.

In this MAN truck is 1 of the D26E6 engines that I build and like every year, there are some changes in the regulations, so you have to adjust the engine management accordingly.

Again this year has a lot to do with the way they measure speed with the FIA race management. It is therefore important to get as close to the speed as possible and then you talk about 0.2Kmh determines which we can regulate and you also hear in the video that the motor reacts to every bump on the tarmac and that we also much faster on speed governing then the other teams that only use the GPS speed measurement from the FIA organization that a lot slower in response something that you can see in the data logs where we compare data from both GPS speed inputs.

Smoke at FIA truck racing is a No Go but the FIA European Championship is the F1 of truck racing. If you do not manage it well you and up on the back of the feeld and this max 13L engine capacity you can easily go over the 5000Nm torque and 1000Hp which can be much more but just like in the Rally Sport there is an inlet restrictor for the turbo compressor that limits the amount air that enters the engine. when it comes to power and torque with a race truck, you have a triangle to handle things best as for trying to inject too much fuel at high revs to make power you I get smoke. I try to inject a lot of fuel at low speed and you also try to make a lot of torque / power still have oxygen left to burn fuel smokeless but then there is a chance that the fuel pump cannot deliver this fuel, and yes we already have a fuel pump that can pump more fuel which also requires less power to do this compared to what other teams use but we also have a driver who is gaining experience by making a lot of race kilometers and a load more power means that the power itself in the last gear itself above 100Kmh just breaks traction ending up with drifting and skating the rear is not a problem only you will drive slower and yes there are enough buttons that you can turned that stuck to the engine management system to control the power per corner just like in Formula 1 car, but believe if you are all racing you need all the concentration and attention and therefore not all race drivers are able to turn knobs to set engine power as needed and it requires experience to do all of this during a race or you have to have very good control over your accelerator peddle.

Was a successful weekend with a compliment from an FIA official that we can participate between the teams that are supported by the factory, with the remark if an engine supplier pulls the plug on support then there are options for the racing teams to continue. So yes they are aware that a truck manufactured can pull out.

[ame="http://www.youtube.com/watch?v=OuE7IlncVlA"]FIA Truck Race testing Autodrom Most team Rennabteilung der Heinrich Hecker KG part 1 - YouTube[/ame]

[ame="http://www.youtube.com/watch?v=SqurHl2dIGM"]FIA Truck Race testing Autodrom Most team Rennabteilung der Heinrich Hecker KG part 2 - YouTube[/ame]

In this MAN truck is 1 of the D26E6 engines that I build and like every year, there are some changes in the regulations, so you have to adjust the engine management accordingly.

Again this year has a lot to do with the way they measure speed with the FIA race management. It is therefore important to get as close to the speed as possible and then you talk about 0.2Kmh determines which we can regulate and you also hear in the video that the motor reacts to every bump on the tarmac and that we also much faster on speed governing then the other teams that only use the GPS speed measurement from the FIA organization that a lot slower in response something that you can see in the data logs where we compare data from both GPS speed inputs.

Smoke at FIA truck racing is a No Go but the FIA European Championship is the F1 of truck racing. If you do not manage it well you and up on the back of the feeld and this max 13L engine capacity you can easily go over the 5000Nm torque and 1000Hp which can be much more but just like in the Rally Sport there is an inlet restrictor for the turbo compressor that limits the amount air that enters the engine. when it comes to power and torque with a race truck, you have a triangle to handle things best as for trying to inject too much fuel at high revs to make power you I get smoke. I try to inject a lot of fuel at low speed and you also try to make a lot of torque / power still have oxygen left to burn fuel smokeless but then there is a chance that the fuel pump cannot deliver this fuel, and yes we already have a fuel pump that can pump more fuel which also requires less power to do this compared to what other teams use but we also have a driver who is gaining experience by making a lot of race kilometers and a load more power means that the power itself in the last gear itself above 100Kmh just breaks traction ending up with drifting and skating the rear is not a problem only you will drive slower and yes there are enough buttons that you can turned that stuck to the engine management system to control the power per corner just like in Formula 1 car, but believe if you are all racing you need all the concentration and attention and therefore not all race drivers are able to turn knobs to set engine power as needed and it requires experience to do all of this during a race or you have to have very good control over your accelerator peddle.

Was a successful weekend with a compliment from an FIA official that we can participate between the teams that are supported by the factory, with the remark if an engine supplier pulls the plug on support then there are options for the racing teams to continue. So yes they are aware that a truck manufactured can pull out.

[ame="http://www.youtube.com/watch?v=OuE7IlncVlA"]FIA Truck Race testing Autodrom Most team Rennabteilung der Heinrich Hecker KG part 1 - YouTube[/ame]

[ame="http://www.youtube.com/watch?v=SqurHl2dIGM"]FIA Truck Race testing Autodrom Most team Rennabteilung der Heinrich Hecker KG part 2 - YouTube[/ame]

New DID1 diesel ECU for common rail diesel engines can run up to 8 cylinders.

Ssangyong ML 270 CDI 2.7L diesel

Mercedes Benz OM611 (220CDI), OM612 (270CDI), OM613 (320CDI) plug and play wiring

Mercedes Benz OM628 4.0 V8

Mercedes Benz OM646 (220CDI), OM647 (270CDI), OM648 (320CDI)

Toyota 1KD-FTV 3.0 4 cylinder found in J90 Land Cruiser

And may soon to follow including truck engines with PD or pump injectors.

External injector driver box needed! Next up Scania V8 PD injectors. Was planning to use a Cummins ISB or QSB but we are out of stock so will run that one later on as well.

[ame="http://www.youtube.com/watch?v=aFNJIWc4tzc"]YouTube[/ame]

Ssangyong ML 270 CDI 2.7L diesel

Mercedes Benz OM611 (220CDI), OM612 (270CDI), OM613 (320CDI) plug and play wiring

Mercedes Benz OM628 4.0 V8

Mercedes Benz OM646 (220CDI), OM647 (270CDI), OM648 (320CDI)

Toyota 1KD-FTV 3.0 4 cylinder found in J90 Land Cruiser

And may soon to follow including truck engines with PD or pump injectors.

External injector driver box needed! Next up Scania V8 PD injectors. Was planning to use a Cummins ISB or QSB but we are out of stock so will run that one later on as well.

[ame="http://www.youtube.com/watch?v=aFNJIWc4tzc"]YouTube[/ame]

I'm always so impressed when I come back to this thread. Keep up the good work. Do you have any solutions for Factory ECM tuning? Big marine industry where I am, and they always are looking for a bit more.

Can be that there is money to be made but I steer away from OEM ECU hardware as we test OEM related hardware on new R&D engines. Dos not land well with some of my customers messing with there hardware. Get it.

We dyno tested the Ny Titan Semi hobby sport truck puller and gain 5% more power just by timing and taking some fuel out. Yes these last generation engines will burn all oxygen and the margin from no smoke in max torque range is about 10Hp only. Top end is a other story as it run a inlet restrictor on top end 2500Rpm to max power @ 1500Rpm it only gains 70Hp max so torque is moving up when RPM drops.

As this engine is so efficient it dos not produce a load of exhaust volume so I’m looking for a Garrett GTX gen 2 with a 0,8A/R turbine housing 88mm inducer on compressor. We now running a S588SX-E but even with a 0.85A/R we are 0,5Bar short on target so any suggestion on what we can use even custom build if needed.

[ame="http://www.youtube.com/watch?v=CbNIyrngBQc"]Volvo van Dijk Ny Titan Truck puller dyno test 1 - YouTube[/ame]

[ame="http://www.youtube.com/watch?v=tu6Y7ZX7eU0"]Volvo van Dijk Ny Titan trukpuller last dyno test. less fuel more power - YouTube[/ame]

As this engine is so efficient it dos not produce a load of exhaust volume so I’m looking for a Garrett GTX gen 2 with a 0,8A/R turbine housing 88mm inducer on compressor. We now running a S588SX-E but even with a 0.85A/R we are 0,5Bar short on target so any suggestion on what we can use even custom build if needed.

[ame="http://www.youtube.com/watch?v=CbNIyrngBQc"]Volvo van Dijk Ny Titan Truck puller dyno test 1 - YouTube[/ame]

[ame="http://www.youtube.com/watch?v=tu6Y7ZX7eU0"]Volvo van Dijk Ny Titan trukpuller last dyno test. less fuel more power - YouTube[/ame]

It dos almost make 2x max torque of standard 750Hp Volvo D16K 16L engine @ 1500Rpm so what will this be on power? So 1000Hp is bit low mate. A 13L race engine will make 1000Hp @ 1430Rpm with no smoke.Did it make over 1000 ?

https://www.volvotrucks.com/content/dam/volvo/volvo-trucks/masters/euro-6/pdf/trucks/volvo-fh-series/driveline/Volvo-FH-Series_Specifications_Driveline_UK.pdf

Not all easy going. dyno start jumping @ 1400RPM holding powerrr

[ame="http://www.youtube.com/watch?v=Q2Jkx95NzkM"]Ny Titan 1400Rpm test - YouTube[/ame]

Last edited:

Some weeks back we had a small race @ lausitzring Germany where FIA European truck race meets British Truck race competitors.

Out of top 4 we build two truck race engines. If it where not for the fuelpump limitation we would have run one of them @ 1300Hp plus.

[ame="http://www.youtube.com/watch?v=xo32ur4kJqU"]We build truck race engines - YouTube[/ame]

Out of top 4 we build two truck race engines. If it where not for the fuelpump limitation we would have run one of them @ 1300Hp plus.

[ame="http://www.youtube.com/watch?v=xo32ur4kJqU"]We build truck race engines - YouTube[/ame]

Leiffi

New member

OK, so about 1300 , is that possible through restrictor ? Hub or calculated crank hp ?It dos almost make 2x max torque of standard 750Hp Volvo D16K 16L engine @ 1500Rpm so what will this be on power? So 1000Hp is bit low mate. A 13L race engine will make 1000Hp @ 1430Rpm with no smoke.

https://www.volvotrucks.com/content/dam/volvo/volvo-trucks/masters/euro-6/pdf/trucks/volvo-fh-series/driveline/Volvo-FH-Series_Specifications_Driveline_UK.pdf

Not all easy going. dyno start jumping @ 1400RPM holding powerrr

Ny Titan 1400Rpm test - YouTube

What about MVJ2 , 2000 ?

If a racetruck can make about 1050Hp with a 63 mm restrictor a hobbysport can make 1450Hp with a 74mm restrictor so yes 1300Hp is close on the hub. Drive train losses can be from 10 to 15% I tnink.OK, so about 1300 , is that possible through restrictor ? Hub or calculated crank hp ?

What about MVJ2 , 2000 ?

MVJ2 Back in 2013 we had 2059Hp and now we went up 2000Nm more but that’s really max on the PD system. 16L volvo Commonrail will pull more Nm @ same boost pressure the MVJ2 dos. Fuel models confirm test results.