I have questions

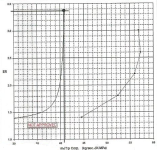

- is this 1350f EGT across all 4 engines?

- how much boost and fuel flow at egt?

- any chances of boost leaks?

- what are air intake temps?

-All about the same.

-40-41 psi, 29-30 US g/h at WOT (110-115 l/h)

-no boost leaks

-do not know for sure