You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

My 4bt jeep project

- Thread starter dzljon

- Start date

6 speed 90

Drunken hillbilly

You do very very nice work. :clap: keep it up!

dzljon

Aviation TIG Welder

You do very very nice work. :clap: keep it up!

Thanks!

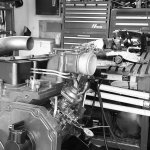

Reshaping the manifold ports

Sent from my iPhone using Tapatalk

glad to see im not the only one who did this,

years back when I did my fummins swap i couldnt find an Industrial manifold so I bought a 3rd gen and blend matched the head to a CR and the manifold to a 12v, Quite the **** storm fallowed like i had ran over someones dog and finished it off with a shovel.

How much does one of them smaller Plasma tables run? Ive been wanting one for years