So, here's a question for you guys, I'm running 4 nitrous kits on the car, not for the purposes of hosing its face off but more so for the purpose of spreading the love out with multiple small kits on simple digi-set timers because I hate progressive controllers and PWM solenoids.

One kit will be a tiny .030 or so that comes on with the trans brake button, after that I'll have a purge solenoid and two .125 solenoids to work with and turn on whenever i want after release of trans brake down the track using the digi-set timers.

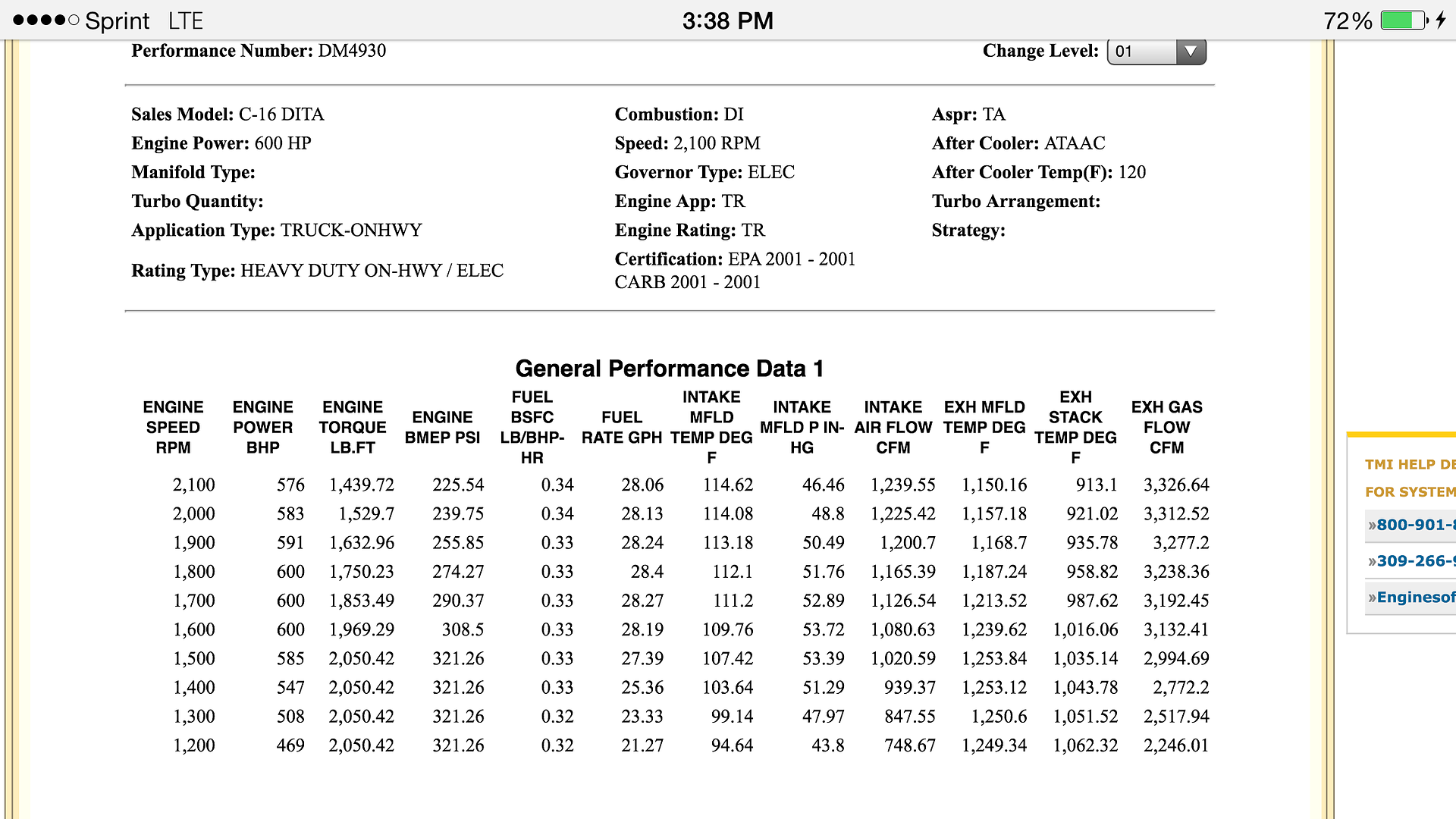

My question to you is, where would you put the nozzles in the system? There are two very specific trains of thought here, one being that furthest away gives the most IC effect, the other being that closest to the engine gives the most bang for the buck. My initial thought is to put the spool-aid shot, the first small shot on the purge solenoid and one of the .125 on the charge pipe just inside the firewall on the compressor discharge side of the intercooler, then the other .125 solenoid which would be my "third, big kit" with the nozzle mounted on the other charge pipe just inside the firewall, between the IC and the engine.

Plan is to have the spool aid on whenever the trans brake is on, with the other three kits activated by digi-set timers, likely bringing the first small kit on right after the hit and before the 60' if the tires can take it, then the first .125 shortly after the 60' if the tires can take it then likely the "third big kit" right around the 330' likely right after the lockup clutch is applied and used as a MPH tool.