BC847

New member

Most of my experience in bonding metal is by way of 5~15% silver-brazing typical copper piping in HVAC&R stuff. Else, not very often with a Dayton 100amp buzz-box ac stick-welder. My Dad had a VERY old (75years?) 400amp buzz-box. It's massive!Your welds look fine! Sweet looking setup there, dont worry my tig welds look worse than that. Guess thats what I get for only using tig once a month.

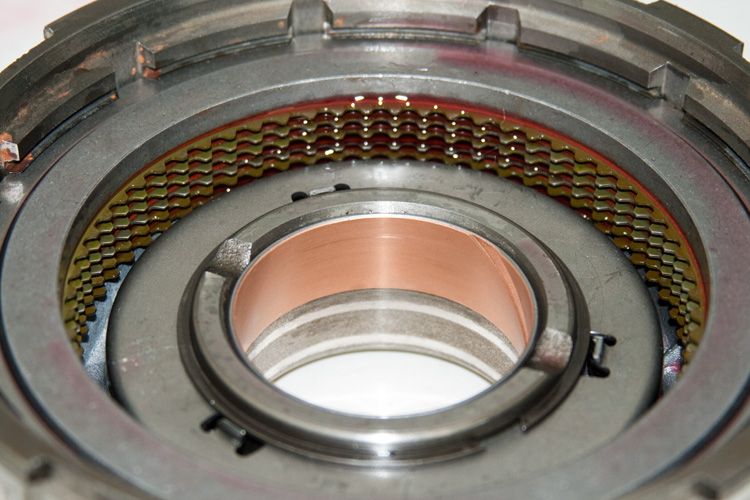

However, five or so years ago, a former employer sold me a slightly used Miller Maxstar 150 STL for less than $1000 IIRC. It included the wah-wah peddle. I used it to TIG the SS hot-stuff and the CRS of the exhaust plumbing. I'd never welded SS before.

That being said, the vast majority of the welds in the turbo and exhaust stuff are without filler-metal being added.

- Those pipe-to-pipe butt-joints were cut flat, then trued with a 16" disc-sander. Having the joints butt-up very well, I simply fluidized a puddle all the way around.

- The V-band flanges are of the stepped-type in that they can fit a number of size pipes. I simply used the neighboring step in the flange as filler, and flowed it down into the pipe.

- Rather than worry with purging everything with Argon along the way, I used the powder/alcohol mix stuff specifically for welding SS (I can't remember its name).

- I used my exhaust-pipe expanders to hold all the round stuff true to one another. THAT worked sweetly.

I learned how SS holds the torch heat MUCH more that comparable steel metal. :doh:

I learned the importance of jig/fixtures for holding stuff and welding in short dashes (warping). :doh:

There's to much undercutting for my liking. :doh:

I need a LOT more practice!

I'm still recovering from being burn't-out with the turbo-build. :charger:

We poked around under the truck and hood this past weekend.

- Many of the engine oil seals are weeping. I figure the 285,000 miles on the short-block have the pistons/cylinders less than parallel & true. Bringing the heap up to full boost . . . . . often . . . . doesn't help.

- Found the water-pump was weeping around its shaft-seal. Replaced it (2nd in 25 years).

- Checked/adjusted the valve-lash.

- Cleaned/oiled the air-filter.

- Checked/tightened all the fasteners in the passenger-side of the engine-bay.

The local track is suppose to open this coming Thursday with a T&T. The National Weather Service says: "No, they ain't".

Last edited: