NakeDiesel

Smoke'n in the Mud

- Joined

- Jan 20, 2010

- Messages

- 1,116

I bought the irwin ones, only ones I could find at steve's wholesale, I know others make them from bluepoint to s&k. Once I figured out you had to beat it onto the bolt head with a hammer, I put a 7/8" socket in 1/2" drive and then used an adapter to go to my 3/4" ratchet and using the bar over tool on the back to hold the engine from turning over, busted it right loose, so I think it worked pretty good. Could have been a lot worse.

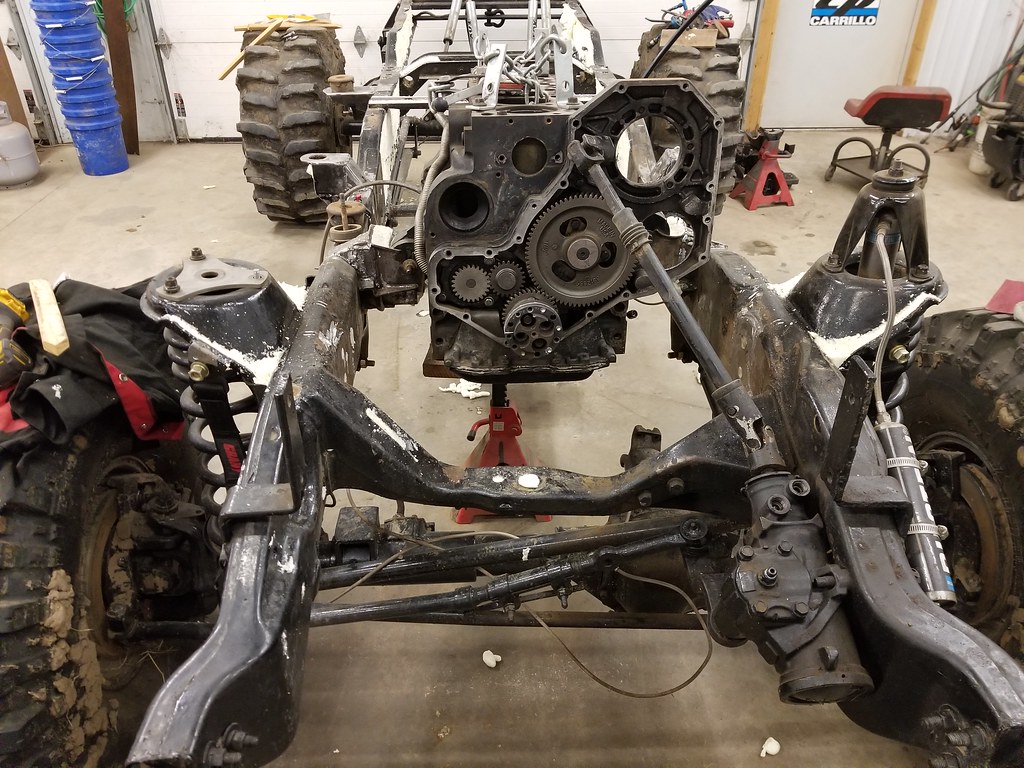

This is the first time I've relocated an engine, so I feel like I'm moving at a snails pace, but trying to keep the engine on the same plane it was on and ensure I don't go too far back so I break the class rules, but not too far forward where I don't get all the benefits....

This is the first time I've relocated an engine, so I feel like I'm moving at a snails pace, but trying to keep the engine on the same plane it was on and ensure I don't go too far back so I break the class rules, but not too far forward where I don't get all the benefits....