shortbusdriver

this guy

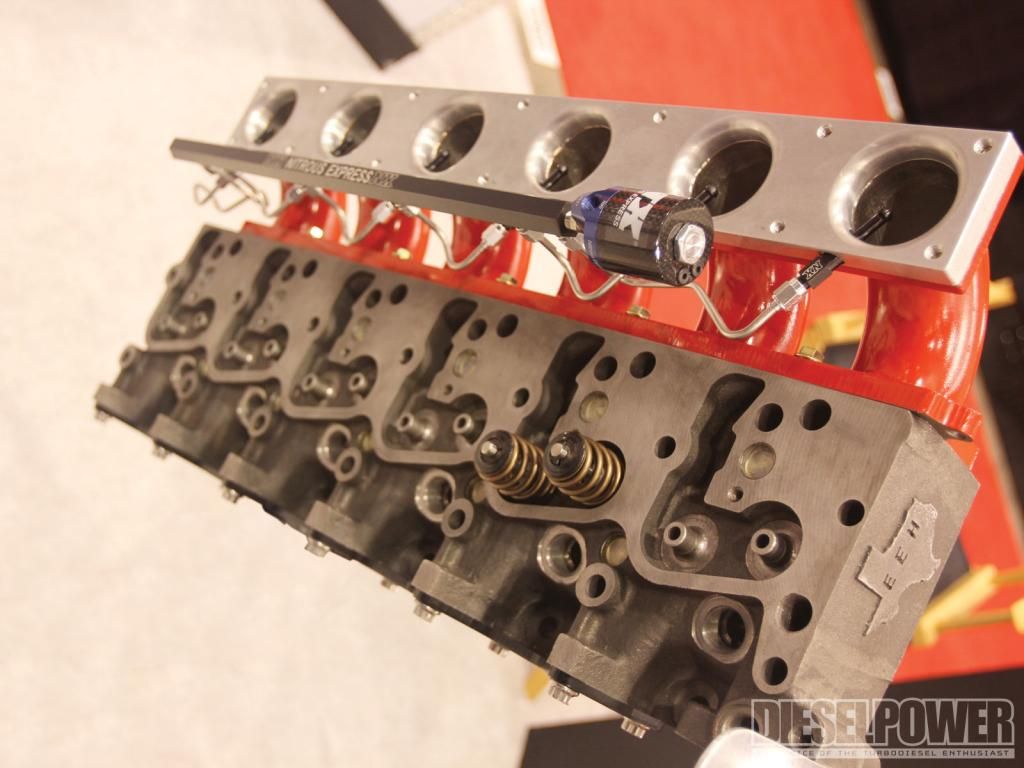

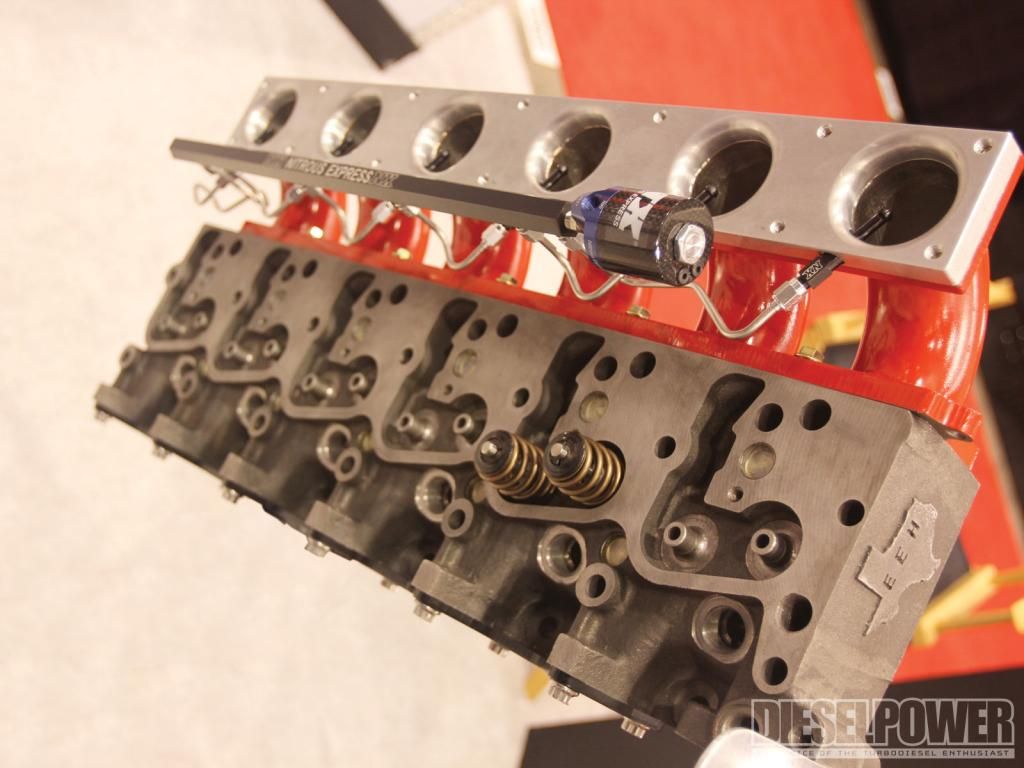

Looking for someone running a Cummins with a nitrous rail with a nozzle in each cylinder similar to this...

Making a new product for people running or interested in running a setup like this and want to see what someone else that has set something up like this thinks about it and see if they have any ideas and what not. If you are helpful you could be rewarded with a heavy discount on it, or a hug.

Don't really want to put out there what it is until I get them done.

Making a new product for people running or interested in running a setup like this and want to see what someone else that has set something up like this thinks about it and see if they have any ideas and what not. If you are helpful you could be rewarded with a heavy discount on it, or a hug.

Don't really want to put out there what it is until I get them done.