ahale2772

New member

so ive finally started puttin in time on porting my spare head. (p-pump 7mm head with log milled off and manifold)

im gona keep posting pictures to see if anyone has any advice on what to watch out for, what to port, and what swirl charicteristics to leave.

ive started on the intake runners, allready matched my maifold flange to the ports, and ive got a gasket that I will match later.

im gona start by making the intake runners a little more round to compensate for the round runners I'm using on my intake. I figure if i optimise how the intake flows I can gain some CFM over a stock log... is that wrong? should I leave the runners alone?

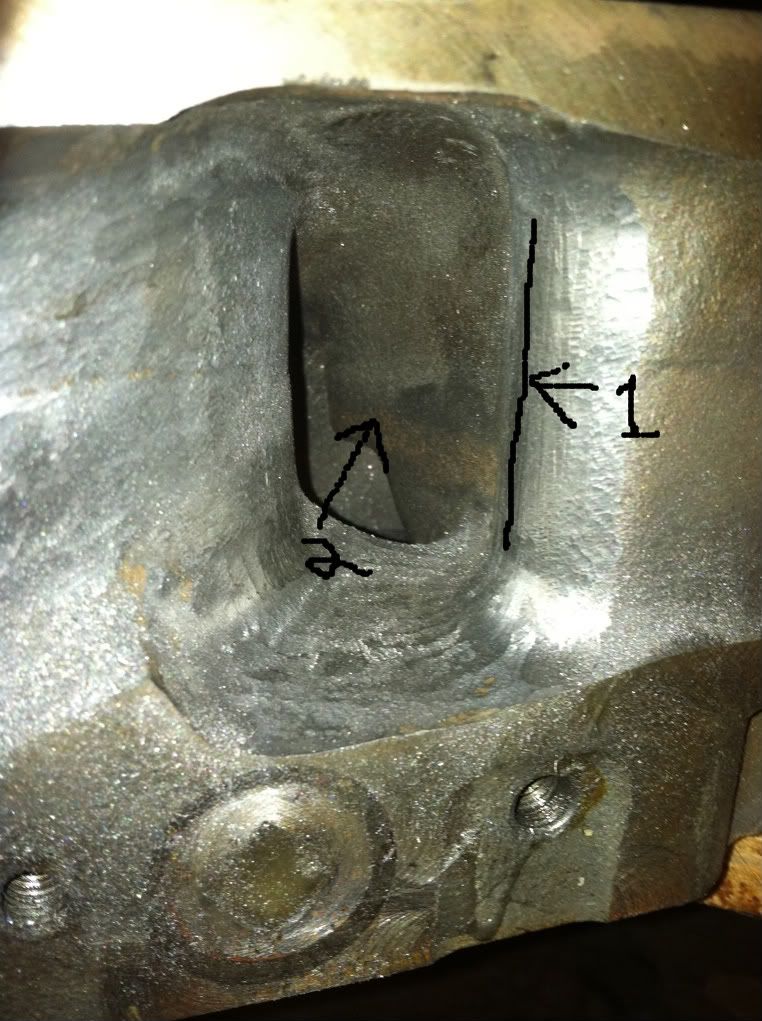

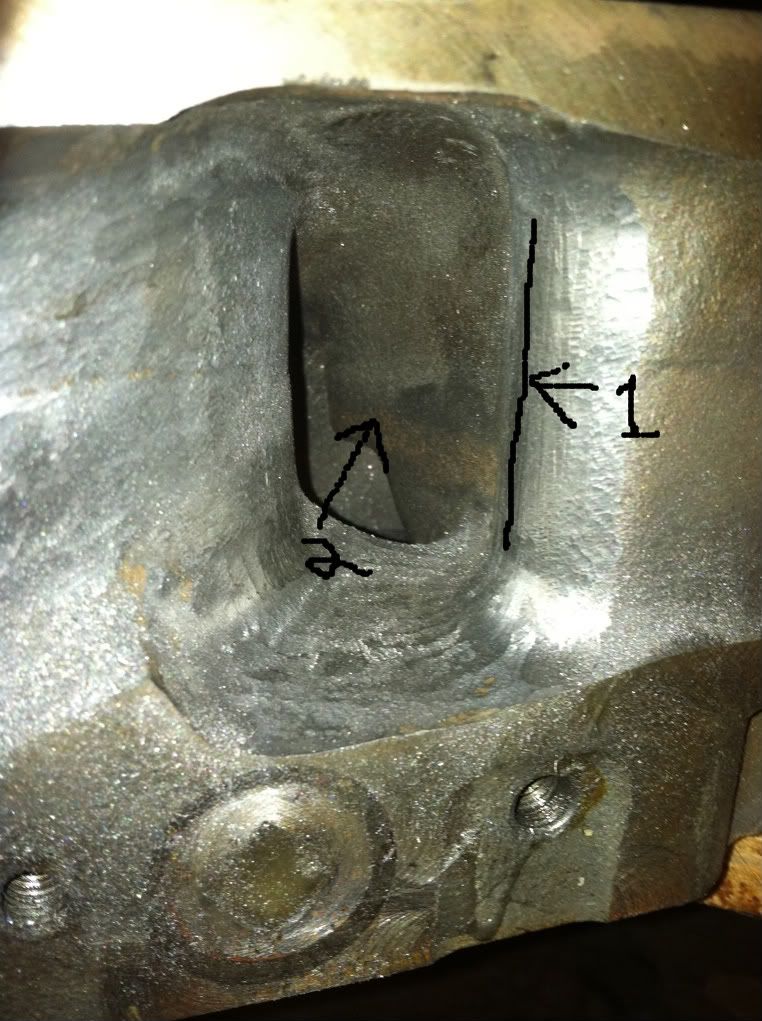

anyways ive started smoothing out the port walls and removing some obstructions. ive smoothed out the area around the pushrod holes untill its only about 1/8 thick... kinda alot but it eliminates a bump here... (#1)

the area labled as #2 is the next area im concerned about, its the wall before the turn into the bowl, should I just clean it up or try to remove some? im gona focus on the ceiling and that wall because it is the main path the air takes before entering the bowl to swirl

next... im wondering what kind of material i should remove below the valve seats, there is alot there and I dont know how much to take off the walls. there is about 1/8 of an inch of material that seems to be supporting the seats, and in pictures such as this....

the area is almost completly removed (i dont want to have the seats pound into the head

the area is almost completly removed (i dont want to have the seats pound into the head

any advice is good, im a newb at porting cummins heads but i have done a ton of reading...

thanks

im gona keep posting pictures to see if anyone has any advice on what to watch out for, what to port, and what swirl charicteristics to leave.

ive started on the intake runners, allready matched my maifold flange to the ports, and ive got a gasket that I will match later.

im gona start by making the intake runners a little more round to compensate for the round runners I'm using on my intake. I figure if i optimise how the intake flows I can gain some CFM over a stock log... is that wrong? should I leave the runners alone?

anyways ive started smoothing out the port walls and removing some obstructions. ive smoothed out the area around the pushrod holes untill its only about 1/8 thick... kinda alot but it eliminates a bump here... (#1)

the area labled as #2 is the next area im concerned about, its the wall before the turn into the bowl, should I just clean it up or try to remove some? im gona focus on the ceiling and that wall because it is the main path the air takes before entering the bowl to swirl

next... im wondering what kind of material i should remove below the valve seats, there is alot there and I dont know how much to take off the walls. there is about 1/8 of an inch of material that seems to be supporting the seats, and in pictures such as this....

any advice is good, im a newb at porting cummins heads but i have done a ton of reading...

thanks