dieselbeef

dick doggin

how does it affect the lifespan of the vp being 10% higher pressures

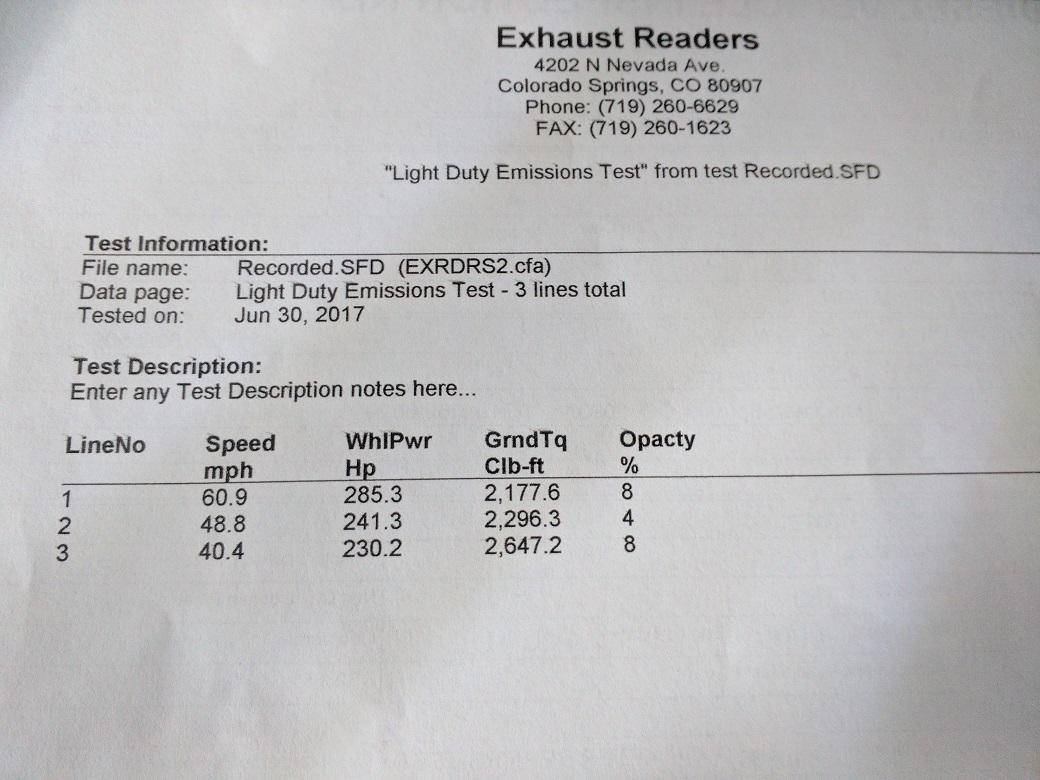

Pressure increases until the needle valve in the injector lifts (approximately 4,500

psi) and injection begins. Pressure continues to rise due to the VP44 pump

pressurizing the fuel faster than the holes in the injector can discharge it. This

pressure can reach approximately 20,000 psi at maximum fuel flow.

how does it affect the lifespan of the vp being 10% higher pressures

No wiretap for me. Still seems like common sense says the extra pressure means extra wear to me though. Besides I thought that the "breakthrough" of the v2 tuning was that you could now get away with running larger fuel/turbo setups, and be able to tune it work nicely?

Is higher pop pressure going to cause more seat wear?

being the ignorant one here..would not bosch have done any kind of this research to reach a recommended pop pressure?

also I think the statement was made that press builds beyond pop press by the vp..help me to understand that if the inj pops off..isn't the press releasing?

cuz im really just not following most of this for some reason idk