We just finished the championship becoming second place this year with our semi truck.

After the championship the race is on for next year to come up with a stronger more power full engine.

We are one of the 4 teams that run an electronic controlled engine in our class doing an the R&D our self as some teams have factory support like Iveco has.

Some of the specifications.

Engine: DC1601 V8 15,6liter 32Valve

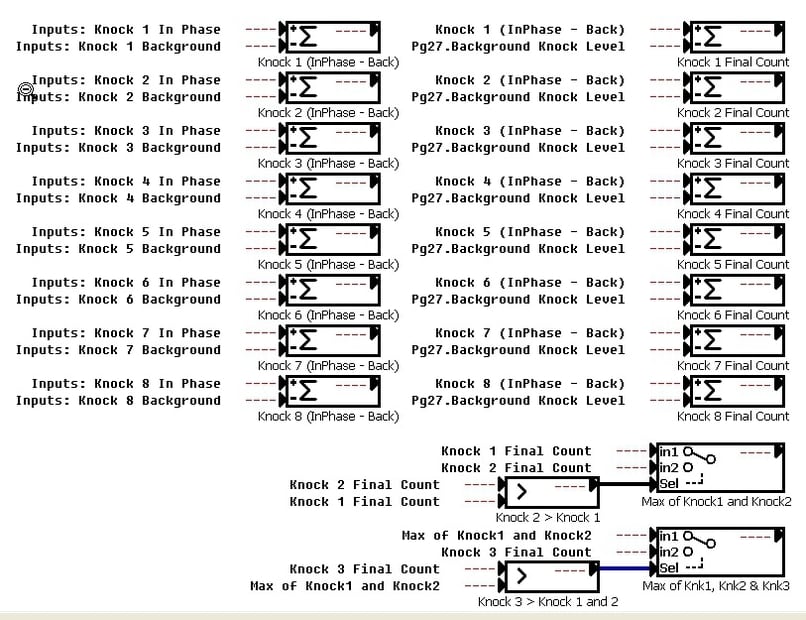

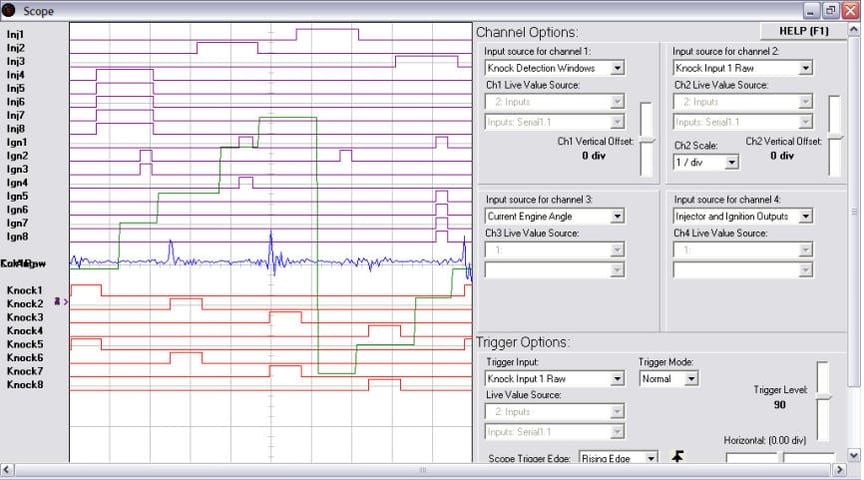

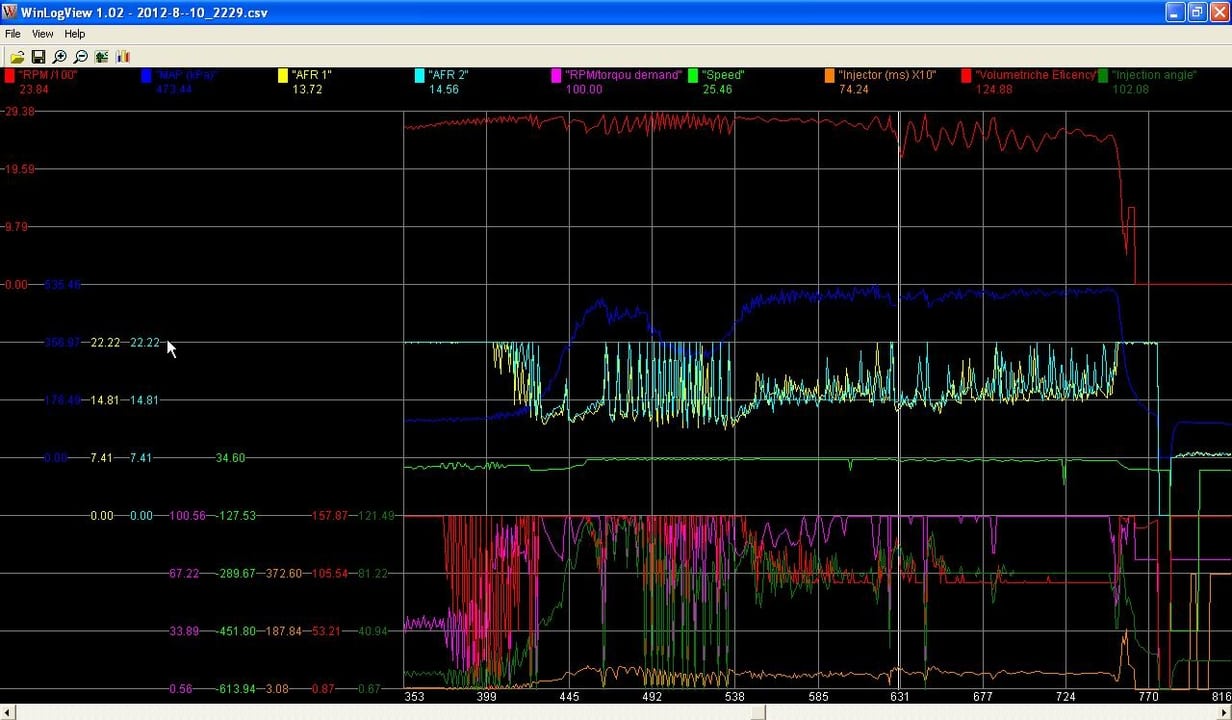

ECU system: Adaptronic 1280DI

Max RPM: 2900

Estimated Hp: 2000+

Diesel Injection system: BOSCH pump injectors camshaft activated.

Injectors upgrade

Camshaft standard ones

Turbochargers: 2x HX60 Holset.

Charge air cooling system: Intercoolers placed in water tank.

Gearbox: ZF

Rear axel: DAF

Max weight including drivers: 9500Kg

Website: De Manne van Janne

Some pictures.

Just to have an idea what it all about.

Truckpulling de Manne van Janne2 Scania V8 Almkerk 2011 pull3 - YouTube

Manne van Janne 2 finale Etten-leur 2011.wmv - YouTube

Trucktrek - Manne Van Janne 2 - YouTube

Truckpulling de Manne van Janne2 Scania V8 Montfoort 2012 pull3 - YouTube

At the begin of the year we had it all going in a good direction with the new hi pressure injectors and new exhaust manifold to give more flow making more Hp

Pretty soon we discover that the turbochargers where not up to the job blowing them up and we faced a whole lot of other things having an engine that did have big changes in performance even after we jump back to old specifications of last year but we manage to solve this but as a result we could not experiment as we needed all the championship point.

What next is that we will start again @ the point where we have stopped before. Currently we are working on the turbo specification and exhaust manifolds and having the cylinders heads put together.

We also like to play a bit. In this case pulling the sled of the track.:lolly:

Manne van Janne 2 Semi truckpuller ALS kicking in at the start. Run 1 in Berts 2012 - YouTube

After the championship the race is on for next year to come up with a stronger more power full engine.

We are one of the 4 teams that run an electronic controlled engine in our class doing an the R&D our self as some teams have factory support like Iveco has.

Some of the specifications.

Engine: DC1601 V8 15,6liter 32Valve

ECU system: Adaptronic 1280DI

Max RPM: 2900

Estimated Hp: 2000+

Diesel Injection system: BOSCH pump injectors camshaft activated.

Injectors upgrade

Camshaft standard ones

Turbochargers: 2x HX60 Holset.

Charge air cooling system: Intercoolers placed in water tank.

Gearbox: ZF

Rear axel: DAF

Max weight including drivers: 9500Kg

Website: De Manne van Janne

Some pictures.

Just to have an idea what it all about.

Truckpulling de Manne van Janne2 Scania V8 Almkerk 2011 pull3 - YouTube

Manne van Janne 2 finale Etten-leur 2011.wmv - YouTube

Trucktrek - Manne Van Janne 2 - YouTube

Truckpulling de Manne van Janne2 Scania V8 Montfoort 2012 pull3 - YouTube

At the begin of the year we had it all going in a good direction with the new hi pressure injectors and new exhaust manifold to give more flow making more Hp

Pretty soon we discover that the turbochargers where not up to the job blowing them up and we faced a whole lot of other things having an engine that did have big changes in performance even after we jump back to old specifications of last year but we manage to solve this but as a result we could not experiment as we needed all the championship point.

What next is that we will start again @ the point where we have stopped before. Currently we are working on the turbo specification and exhaust manifolds and having the cylinders heads put together.

We also like to play a bit. In this case pulling the sled of the track.:lolly:

Manne van Janne 2 Semi truckpuller ALS kicking in at the start. Run 1 in Berts 2012 - YouTube