| Advertisement |

|

|

|

|

|

|

|

If this is your first visit, be sure to check out the FAQ by clicking the link above.

You may have to register before you can post: click the register link above to proceed.

To start viewing messages, select the forum that you want to visit from the selection below.

|

09-30-2019, 08:46 AM

09-30-2019, 08:46 AM

|

#921

|

Name: tall boy

Title: Too Much Time

Status: Not Here

Join Date: Sep 2012

Member`s Gallery

Posts: 797

|

So last pull of this year. Did look like we found some more power with changing injector timing a bit but need more boost on this machine and can not work out what turbo?

Looking into a Garrett 88mm inducer but need something like a 120mm or 130mm inducer turbine side with a 0.8A/R TH. Or maybe only possible to use a smaller turbine wheel.

|

|

|

|

10-13-2019, 06:36 AM

10-13-2019, 06:36 AM

|

#922

|

Name: tall boy

Title: Too Much Time

Status: Not Here

Join Date: Sep 2012

Member`s Gallery

Posts: 797

|

Real fun project to support this from Dieselmeken AB and there Mercedes OM648 engine.

They build some insane big injectors and CP pump for this engine. Think it’s idle on around 5 microseconds if you take off the injector dead time to open the injector so idle can be a bit on off sometimes but yes engine makes fantastic power and currently running a S369SX-E turbo boosting up intake air pressure.

|

|

|

|

10-13-2019, 11:16 AM

10-13-2019, 11:16 AM

|

#923

|

Name: jasonc

Title: Too Much Time

Status:

Here

Join Date: Nov 2009

Member`s Gallery

Posts: 4,412

|

That little thing is bad ass. What rpms was it turning up to in that vid?

|

|

|

|

10-13-2019, 01:38 PM

10-13-2019, 01:38 PM

|

#924

|

Name: tall boy

Title: Too Much Time

Status: Not Here

Join Date: Sep 2012

Member`s Gallery

Posts: 797

|

Quote:

Originally Posted by jasonc

That little thing is bad ass. What rpms was it turning up to in that vid?

|

For now it sets @ 5500Rpm

|

|

|

|

10-20-2019, 02:34 AM

10-20-2019, 02:34 AM

|

#925

|

Name: tall boy

Title: Too Much Time

Status: Not Here

Join Date: Sep 2012

Member`s Gallery

Posts: 797

|

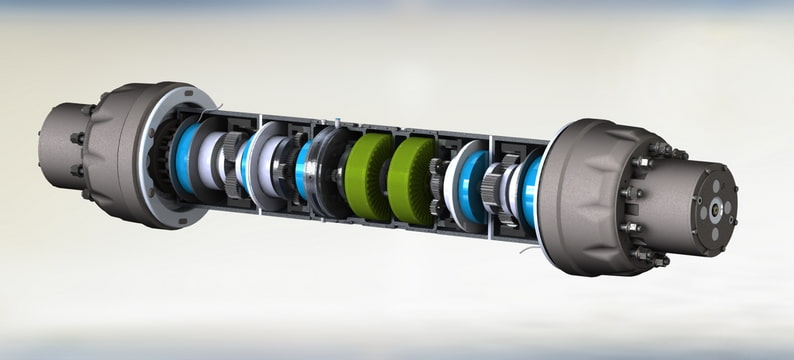

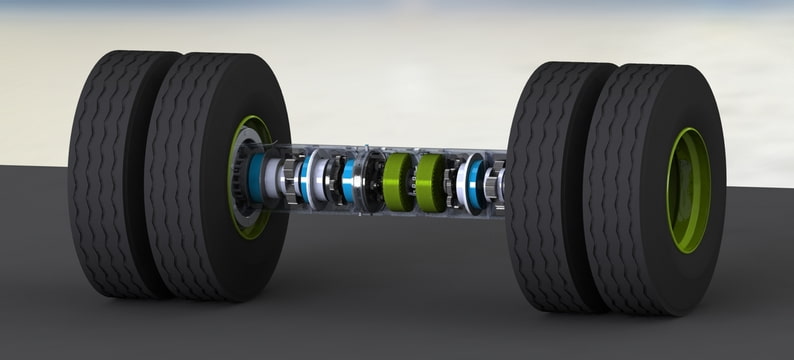

Something we have been working on for some time and yes this axle it’s electrical but we can also put the Smech Grears in to a gearbox driven of a diesel engine for example.

This axle has two E motor and delivers 220Kw nominal and 460Kw peak power and total weight of only 40Kg for 2 E motors and in lowers gear it pulls 16 tons on nominal power.

Have to have this axle running next year same time on a hydrogen power semi truck but it can be any combination most likely it will be diesel and battery power hybrid for long distance use. The idea behind the hybrid with internal combustion engines is that the combustion engine runs on max efficiency all the time so no extra fuel use to keep the DPF and SRC up to temperature on low load. Battery power will be used for acceleration and deceleration power recovery or uphill and downhill same story to get your energy back while going downhill so in all run more efficient. Other options will be on applications with a large drive train like 8x8 fire tender on airports where 800 to 1000Kw is needed for fast response time so good acceleration is a must but more payload due to less space needed for the drive train is also very welcome same as independent control between the drive train and fire pumps for example.

Smech Grear is a automatic gearbox and it’s mechanical shifting and your able to shift under full power and there is one running with this gearbox on a farm stock pulling tractor.

Smesh-E-Axle Smesh-E-Axle

|

|

|

|

11-09-2019, 06:05 AM

11-09-2019, 06:05 AM

|

#926

|

Name: tall boy

Title: Too Much Time

Status: Not Here

Join Date: Sep 2012

Member`s Gallery

Posts: 797

|

Brands Hatch last truck race weekend of the year 2019

Normally you do all your upgrades during the winter break but no we where there early this year able to test them last weekend on Brands Hatch.

So what have we done? B division trucks. Slam some bigger injectors into the D13 Volvo engine and gain some more power the easy way.

Bint racing with there very old and heavy but bullet prove Detroit 60 series engine still makes loads of power but best way to explain how is bigger is not better but this has a load to do with the cam profile used in these engines and how to set-up your injectors.

A division trucks. Well gain some lose some. Scania engine we testes some things on the fuel system. Point is it works well but now the engine spools the turbo so fast and hard as we now run short of fuel form low to top end and the truck it self gets harder to handle dos not provide the stability to put all this power on the tarmac. Bigger picture for the Scania engine is that we are well on our way to build a new rally truck with a Alison 4000 gearbox and yes do not think this AT can handle the toque well of the Scania engine but turning power down is a lot easier than making more power and plan is to run the AT with the lockup on all the time giving it the feeling of a MT gearbox so fast turbo spool-up will be great to have.

MAN D26 engine. Sometimes you discover new things as a simple switch not active of connected and when this dos work the clutch is unable to hold the engine torque so you run of pole on the starting grid ending up 3e place on last race. But yes told the customer to use an upgraded pressure plate on the clutch. Must say some of the engine management systems and engines for A division trucks are complicated. There is a lot of driver assist things you can adjust with switches helping you to reduce power per gear for example so for most race drivers it takes time to adjust to this finding out what setting work best for them sometimes even running on a lower power setting without them knowing so thatís where data logging comes in so you can find out and tell the driver what to do or next race. Essentially every A division team should a have a race engineering for driver support on and of the race track telling him what to do.

YouTube

|

|

|

|

11-15-2019, 08:26 AM

11-15-2019, 08:26 AM

|

#927

|

Name: Kannif

Title: Rookie

Status: Not Here

Join Date: Mar 2012

Member`s Gallery

Posts: 7

|

The electrics/hybrid stuff is interesting. Just wish we had a diesel/hybrid option in the US.

|

|

|

|

11-20-2019, 10:59 AM

11-20-2019, 10:59 AM

|

#928

|

Name: tall boy

Title: Too Much Time

Status: Not Here

Join Date: Sep 2012

Member`s Gallery

Posts: 797

|

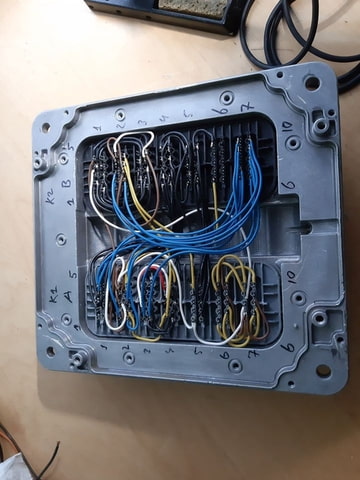

Scania Rally proof concept of engine.

Taking a new a engine apart? Well yes we need all the good part for max performance so not a massive job with massive changes just all the correct part that will last and make great Powerrrr. Proper Engineering often takes less for more. A spec engine build in progress. Ow yes we can build these for race applications as well.

AT is a Alison 4000 series

Last edited by tall boy; 11-20-2019 at 11:01 AM.

|

|

|

|

12-15-2019, 06:18 AM

12-15-2019, 06:18 AM

|

#929

|

Name: tall boy

Title: Too Much Time

Status: Not Here

Join Date: Sep 2012

Member`s Gallery

Posts: 797

|

We had a nice end of year party in Esch of the MVJ truckpulling team.

What will 2020 bring? Well I am currently temporarily inactive with the diesel injection technology until the V8 engine (s) can reliably handle more power, but I'm certainly not going to sit still. We still have truck Race and Rally engines that run on common rail and we can also develop and test the necessary things on that.

As I already mentioned V8 engines. We are going to a lot of effort in to get both the 17L that did so well over the past year, but also the 18.4L that did a little less power despite more cylinder capacity getting the maximum performance going.

|

|

|

|

12-31-2019, 11:59 AM

12-31-2019, 11:59 AM

|

#930

|

Name: allan5oh

Title: Too Much Time

Status: Not Here

Join Date: Oct 2012

Member`s Gallery

Posts: 1,106

|

Has common rail pretty much made unit injectors obsolete in high performance diesel?

__________________

All of your BSFCs are belong to me

|

|

|

|

01-02-2020, 09:28 AM

01-02-2020, 09:28 AM

|

#931

|

Name: tall boy

Title: Too Much Time

Status: Not Here

Join Date: Sep 2012

Member`s Gallery

Posts: 797

|

Quote:

Originally Posted by allan5oh

Has common rail pretty much made unit injectors obsolete in high performance diesel?

|

Common rail in last generation stock configuration out performs any pump injector on low end.

On Hi end or Hi RPM we are working on it to get more flow out of the common rail injectors. <25% more flow can be done with extruder honing. I you need more flow we can use Micro-EDM, hydro-grinding equipment, etc to get that factory quality performance with minimum flow difference between nozzle so yes CR will out perform pump injectors as getting more fuel per stroke in, in a shorter time.

|

|

|

|

01-02-2020, 02:15 PM

01-02-2020, 02:15 PM

|

#932

|

Name: Leiffi

Title: Too Much Time

Status: Not Here

Join Date: Jan 2013

Member`s Gallery

Posts: 1,381

|

Quote:

Originally Posted by tall boy

Common rail in last generation stock configuration out performs any pump injector on low end.

On Hi end or Hi RPM we are working on it to get more flow out of the common rail injectors. <25% more flow can be done with extruder honing. I you need more flow we can use Micro-EDM, hydro-grinding equipment, etc to get that factory quality performance with minimum flow difference between nozzle so yes CR will out perform pump injectors as getting more fuel per stroke in, in a shorter time. |

+150% should be possible Extrude Honing when it is done right with right equipment.

|

|

|

|

01-03-2020, 05:25 AM

01-03-2020, 05:25 AM

|

#933

|

Name: tall boy

Title: Too Much Time

Status: Not Here

Join Date: Sep 2012

Member`s Gallery

Posts: 797

|

Quote:

Originally Posted by Leiffi

+150% should be possible Extrude Honing when it is done right with right equipment.

|

Well not according to our standards. <25% more flow and if you think different not my problem but just to remind you we build top spec racing engines.  . Ow your so loved M11 all mechanical fuel system is banned for truck racing in Europe FIA and BTRA as for this year. That goes for all mechanical fuel systems but must say some Select M11 run well for B division so these live on @ a big budged but @ division no chance there as the MAN D26 E6 engines we build are dominant and one customer slammed on a HX60 80mm induser turbo making 1500Hp based on fuel injected but most say have no lambda data to confirm this so bit over 1300Hp sound more realistic with max Nm set to just under 6000Nm.

Last race in UK where already problematic for M11 all mechanical fuel system getting some power out of these all mechanical PT system getting no low end smoke.

Have fun.

|

|

|

|

01-03-2020, 01:01 PM

01-03-2020, 01:01 PM

|

#934

|

Name: Leiffi

Title: Too Much Time

Status: Not Here

Join Date: Jan 2013

Member`s Gallery

Posts: 1,381

|

I have used +30% nozzles in my working truck unit pumps for about 500000 km now, they were not extruded but hydro grinded like nozzle manufacturers do because it is cheaper and faster, but causes problems after 30% because of wrong type of erosion. Extrude Honing makes it possible to do bigger.

Ask S&S Motorsport, they did ISX XPI injectors some time ago, they are same as Scanias.

Celect M11 had problems with shifter, and it used stock nozzles..

|

|

|

|

01-03-2020, 01:44 PM

01-03-2020, 01:44 PM

|

#935

|

Name: bracker8040

Title: Too Much Time

Status: Not Here

Join Date: Jan 2007

Member`s Gallery

Posts: 818

|

Quote:

Originally Posted by Leiffi

I have used +30% nozzles in my working truck unit pumps for about 500000 km now, they were not extruded but hydro grinded like nozzle manufacturers do because it is cheaper and faster, but causes problems after 30% because of wrong type of erosion. Extrude Honing makes it possible to do bigger.

Ask S&S Motorsport, they did ISX XPI injectors some time ago, they are same as Scanias.

Celect M11 had problems with shifter, and it used stock nozzles..

|

Yes you can go larger than 30% with Extrude Hone, but it makes for a dirty, smokey mess. Even extrude honing only 30% will net you the same dirty, smokey mess.

Micro EDM, and a very minimal bump hone will yield the best results by far.

|

|

|

|

01-03-2020, 03:47 PM

01-03-2020, 03:47 PM

|

#936

|

Name: tall boy

Title: Too Much Time

Status: Not Here

Join Date: Sep 2012

Member`s Gallery

Posts: 797

|

Quote:

Originally Posted by Leiffi

I have used +30% nozzles in my working truck unit pumps for about 500000 km now, they were not extruded but hydro grinded like nozzle manufacturers do because it is cheaper and faster, but causes problems after 30% because of wrong type of erosion. Extrude Honing makes it possible to do bigger.

Ask S&S Motorsport, they did ISX XPI injectors some time ago, they are same as Scanias.

Celect M11 had problems with shifter, and it used stock nozzles..

|

ISX XPI the same. No not even close to Scania ones but we will see as we have to validate them both soon. Still waiting to the ISX ones in and if the Scania nozzle will fit and has the same spay angle it could be they done a load of work for nothing. My first estimation is they are 33% bigger original out of the box as ISX and if you can count to 10 you know why.

Leiffi we test some of the fuel systems before they go in to production and we get to know first hand what it takes to make them works well. Makes you think twice before going stupid.

All the nozzle we used so far are OEM production ones used on off highway and ship engines and they are all made with Micro-EDM, hydro-grinding, and some are silly expensive ass for low number of production but we are up agents factory teams spending loads of money on R&D so how can we win from them? Simple we are independent and are able to combine things/brands and build the perfect engine even down to the level reducing PTO losses as a CR fuel pump consumes a load of power as well so you start concentrating on reducing return fuel from the injectors for example.

|

|

|

|

01-03-2020, 04:08 PM

01-03-2020, 04:08 PM

|

#937

|

Name: Leiffi

Title: Too Much Time

Status: Not Here

Join Date: Jan 2013

Member`s Gallery

Posts: 1,381

|

Scania nozzle will fit because those injectors are same.

I just wonder why your engines dont win anything ?

|

|

|

|

01-04-2020, 04:06 AM

01-04-2020, 04:06 AM

|

#938

|

Name: tall boy

Title: Too Much Time

Status: Not Here

Join Date: Sep 2012

Member`s Gallery

Posts: 797

|

Quote:

Originally Posted by Leiffi

Scania nozzle will fit because those injectors are same.

I just wonder why your engines dont win anything ?

|

Well we won the DTR championship again with the Scania and for the rest you do not know what teams run our engines and yes we do not advertise all our engines and all our A spec engines won races this year so Iím happy. As for truck racing having a better power plant on board is not a easy task getting it on the road. One team even swapped out the truck for a better one as the stiffness to handle the torque was not there so takes more than just an engine to win races. Task for this year will be to instruct the drivers how to use the toque setting a lot better and it will take time and practice for them to adjust to this and maybe some will be on system overload just to keep the truck on the track unable to dial in engine settings.

Just so you all get the picture what will happen on a dry worm track coming out of a corner in 8e gear (gearbox has only 8 gears in hi range) not even using full engine power as the ECU setting for torque not smoke was not on max setting and you can see the driver reduces power not to slide out on the back preventing a power slide. To give you some idea it like a tesla on steroids, it just goes when you want it to go. If you have a closer look @ the data log you notice boost rice RPM is a constant regarding of engine power as TPS is not 100% all the time. Yes we have antilag on mid range power request.  .

Not the same corner and different track but to get an idea on what it looks like.

Same corner bit better power management by the driver end of second corner you see the end stepping out a bit hitting max torque. Fist corner in about 1150Rpm end of second corner about 1580Rpm.

So Leiffi can you build an engine and engine management system that can do all of this???? You make thing sound so easy fooling many others with you smooth talk.

Have fun.

|

|

|

|

01-18-2020, 11:22 AM

01-18-2020, 11:22 AM

|

#939

|

Name: tall boy

Title: Too Much Time

Status: Not Here

Join Date: Sep 2012

Member`s Gallery

Posts: 797

|

Woke up the EVO2 Scania XPI engine today. Set of new injectors was badly needed after running many Rally stages on very bad fuel. The continent of south America & Africa has a big variety of fuel blends.  .

Picture of the new build Dakartruck DKR3 Rally Truck. 12.7L Scania XPI Engine will be the EVO3 with more advanced fuel system tested in 2019 on a race truck able to spool the turbo a lot faster if needed but do not think we going to use that option as saving fuel and there for less weight to carry or more range in distance is more important.

|

|

|

|

02-14-2020, 04:28 AM

02-14-2020, 04:28 AM

|

#940

|

Name: tall boy

Title: Too Much Time

Status: Not Here

Join Date: Sep 2012

Member`s Gallery

Posts: 797

|

|

|

|

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is Off

|

|

|

All times are GMT -5. The time now is 08:35 AM.

|