4 years later here are some T3 manifold pictures.

The rusty one is a heavily hand ported cast 3 piece, the silver one is Stainless Diesel, and the black one is Steed Speed.

Manifold Time Line: I went from stock to a 3 piece due to the stock unit shrinking. I bought the 3 piece on here. It had a crack and I had it "professionally" welded. At a later date it cracked again and I started researching manifolds. I didn't want the same cast 3peice issues as before so I looked at quality one piece designs.

The only USA made ones I could find were Stainless Diesel and Steed. It was a tough decision but I went with stainless diesel, mainly because of the warranty. However, when it arrived I was very disappointed. The manifold was cast with round 24v ports that were half ass ported to 12v. The neck down from the rectangle gasket area to the port was terrible. Even the T3 port did not match my turbo spacer, or the gasket. I called Stainless diesel to ask if my warranty would be voided if I cleaned up the ports and gasket areas. After 3-4 calls with no response over a couple months, I decided to sell it and go with Steed. I mean, if I bought it mainly for the warranty, and voided it to make it fit, what's the point?

Steed's customer service was prompt and cordial...and they even asked for a tshirt size. When the manifold arrived I my jaw dropped. The manifold was actually bolted to a wood plank in a double thick cardboard box, not flopping loosely in a standard box one like Stainless Diesel. I removed it from the plank to reveal it's gorgeous welds, radius edges, and perfect ports. This is what I expect to see when I spend $650 on a manifold! It's almost too nice to bolt to my oil coated 12 valve in a rusty farm truck...almost.

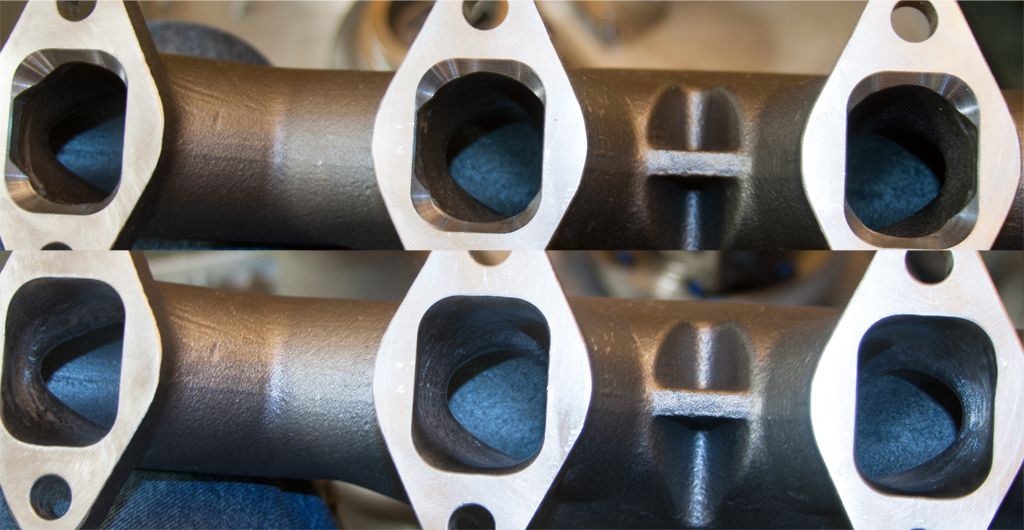

Here are some closer pictures to show what I mean when I say the ports are just chamfered 24v ports. I have measurements somewhere, but I think it was like 1/4" lost at the top and bottom of the port, plus a big chunk on the corners. I feel like it would take days to port these into nice rectangular ports. Compared to this the Steed looks like a smoothed CNC port job which retains the rectangle port design throughout the runners. The other pictures will also show a better angle and radius on all ports, especially the 1 and 6 cylinders compared to the abrupt angle of the cast iron and stainless diesel.

Hopefully the pictures above show the vast differences between these manifolds and help folks make an informed decision on which to buy. To me there is a drastic difference in quality, craftsmanship, and port design between Steed and Stainless Diesel. Material, quality, design, price, service, flow, fitment, I think Steed wins in every category except corrosion. To this day their website still shows no head port shots of the manifold. I think I know why.

PS: Did you notice Steed's bolt holes are more oval the further you get from the center? Go back and look.

Tune in next decade for a review of some injectors I bought in 2011. :hehe: