| Advertisement |

|

|

|

|

|

|

|

If this is your first visit, be sure to check out the FAQ by clicking the link above.

You may have to register before you can post: click the register link above to proceed.

To start viewing messages, select the forum that you want to visit from the selection below.

|

| Dodge Competition and Performance General Dodge Competition and Performance Discussion |

02-16-2009, 01:33 PM

02-16-2009, 01:33 PM

|

#1

|

Name: CSM diesel

Title: Engineer

Status: Not Here

Join Date: Jun 2007

Location: Golden, CO

Member`s Gallery

Posts: 479

|

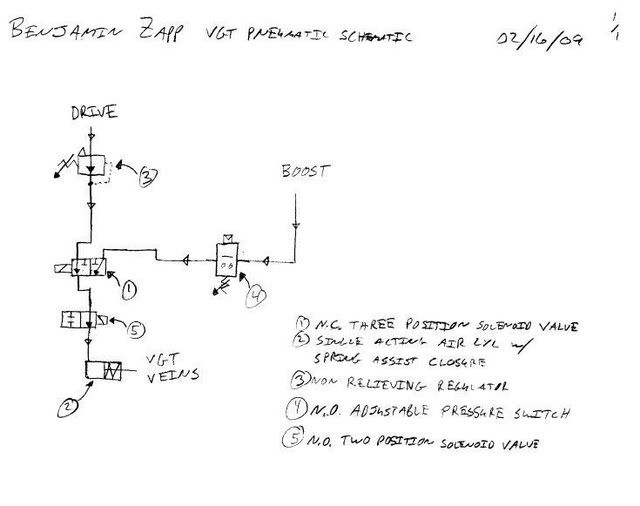

HE351VE on a 12 valve

This is more of an update thread so to speak...

I have found the flanges to build an adapter for the odd ball he351ve flange to adapt it to a standard T3 flange.

I will use a single acting spring closure air cyl. from an exhaust brake.

Here is a pneumatic schematic for the VGT actuation:

The thought process is that the neutral position of the cyl (fully closed by the spring) will hold the veins in their closed position, or slid all the way in (exhaust brake mode.)

This causes concern as the default for the system is fully closed (i.e. exhaust brake mode.) To overcome this a non-relieving adjustable pressure regulator will be in line from the drive pressure port. Drive pressure will hold the air cyl open slightly to the minimum vein position TBD.

From there, as the turbo spools and boost increases, A pressure actuated electric switch (hobbs switch) will close at a TBD boost pressure and activate the three way valve.

This will switch the supply pressure to the air cyl from being the regulated drive pressure to boost pressure.

The vein position will now slide out and open up the volute area as boost pressure increases.

To activate the exhaust brake mode, a two way solenoid valve will be closed allowing the spring in the cyl to close the veins all the way down.

Thoughts? Suggestions? Am I crazy for doing this?

__________________

1998 Dodge Ram 2500, 12 valve

|

|

|

|

02-16-2009, 02:07 PM

02-16-2009, 02:07 PM

|

#2

|

Name: dragnsled

Title: Banned

Status: Not Here

Join Date: Feb 2009

Member`s Gallery

Posts: 262

|

I would do it simple with a wastegate actuator that holds the vgt closed until boost is applied.

|

|

|

|

02-16-2009, 05:29 PM

02-16-2009, 05:29 PM

|

#3

|

Name: sdubfid

Title: Green Behind the Ears

Status: Not Here

Join Date: Sep 2008

Location: Vancouver, BC

Member`s Gallery

Posts: 91

|

would something like that work?

|

|

|

|

02-16-2009, 09:10 PM

02-16-2009, 09:10 PM

|

#4

|

Name: CSM diesel

Title: Engineer

Status: Not Here

Join Date: Jun 2007

Location: Golden, CO

Member`s Gallery

Posts: 479

|

yea looks like it would!

__________________

1998 Dodge Ram 2500, 12 valve

|

|

|

|

02-16-2009, 09:16 PM

02-16-2009, 09:16 PM

|

#5

|

Name: CSM diesel

Title: Engineer

Status: Not Here

Join Date: Jun 2007

Location: Golden, CO

Member`s Gallery

Posts: 479

|

Quote:

Originally Posted by dragnsled

I would do it simple with a wastegate actuator that holds the vgt closed until boost is applied.

|

I have both a wastegate and an air cyl at my disposal. So i will see how it goes.

The problem is that holding it fully closed is like having an exhaust brake on.

__________________

1998 Dodge Ram 2500, 12 valve

|

|

|

|

02-17-2009, 10:35 AM

02-17-2009, 10:35 AM

|

#6

|

Name: dragnsled

Title: Banned

Status: Not Here

Join Date: Feb 2009

Member`s Gallery

Posts: 262

|

Quote:

Originally Posted by sdubfid

would something like that work? |

With the actuator in this picture I would make a bracket and mount it going the other direction so it takes air pressure to open and the internal spring makes it close, that way you have an exhaust brake.

|

|

|

|

02-18-2009, 10:46 AM

02-18-2009, 10:46 AM

|

#7

|

Name: BlackSkyRacing

Title: Living Under a Rock

Status: Not Here

Join Date: Mar 2007

Location: Sparta, WI

Member`s Gallery

Posts: 1,394

|

I was wondering the same thing myself. But I managed to to get a HE451VeTi which came off of an ISL. What I'm hoping is that the exhaust brake that worked on an 8.9L engine will make for rather quick spool in a 5.9

Also, I don't know if you noticed this, But when the Exhaust housing opens up all the way the piston (or whatever you want to call it) slides about 1/8-3/16ths of an inch past the bottom of the turbine wheel... Knowing I have an enormous exhaust housing meaning I probably won't need to open it all the way; I marked in the travel of the arm where the piston is level with the bottom of the exhaust wheel. After measuring the travel from fully closed to "optimal" open and only coming up with 4.5mm at the little hole in the arm and 10mm at the end of the arm where it's cut for gear teeth; I decided to make a little longer arm. I think there will be a few advantages to this. A normal wastegate actuator should be able to travel it's full throw and not go past "optimal" open (if I do my math right when I make the extension). And the actuator should have better control over the exhaust housing since it wont open it too fast and kill the drive pressure. In fact I'm debating using either drive pressure or boost to run the wastegate actuator

Just thought I'd throw that out there, thoughts? BTW I have some pretty nice pics of the comp wheel and the VGT workings in my other thread http://www.competitiondiesel.com/for...540#post613540

__________________

Stan

08 QCSB 4x4 stock (ish) - 68RFE parts test pig

49 Dodge 2.6 pulling project "Gold Digger"

|

|

|

|

02-18-2009, 11:12 AM

02-18-2009, 11:12 AM

|

#8

|

Name: dragnsled

Title: Banned

Status: Not Here

Join Date: Feb 2009

Member`s Gallery

Posts: 262

|

Quote:

Originally Posted by sdubfid

would something like that work? |

I just discovered something!!

This is NOT a HE351v!! However the picture in my avatar is getting one before it goes back in the truck

Quote:

Originally Posted by BlackSkyRacing

I was wondering the same thing myself. But I managed to to get a HE451VeTi which came off of an ISL. What I'm hoping is that the exhaust brake that worked on an 8.9L engine will make for rather quick spool in a 5.9

Also, I don't know if you noticed this, But when the Exhaust housing opens up all the way the piston (or whatever you want to call it) slides about 1/8-3/16ths of an inch past the bottom of the turbine wheel... Knowing I have an enormous exhaust housing meaning I probably won't need to open it all the way; I marked in the travel of the arm where the piston is level with the bottom of the exhaust wheel. After measuring the travel from fully closed to "optimal" open and only coming up with 4.5mm at the little hole in the arm and 10mm at the end of the arm where it's cut for gear teeth; I decided to make a little longer arm. I think there will be a few advantages to this. A normal wastegate actuator should be able to travel it's full throw and not go past "optimal" open (if I do my math right when I make the extension). And the actuator should have better control over the exhaust housing since it wont open it too fast and kill the drive pressure. In fact I'm debating using either drive pressure or boost to run the wastegate actuator

Just thought I'd throw that out there, thoughts? BTW I have some pretty nice pics of the comp wheel and the VGT workings in my other thread http://www.competitiondiesel.com/for...540#post613540  |

Hey you think like me  Boost works better than drive pressure and limiting travel is a must.

Last edited by dragnsled; 02-18-2009 at 11:23 AM.

|

|

|

|

02-18-2009, 11:30 AM

02-18-2009, 11:30 AM

|

#9

|

Name: BlackSkyRacing

Title: Living Under a Rock

Status: Not Here

Join Date: Mar 2007

Location: Sparta, WI

Member`s Gallery

Posts: 1,394

|

Quote:

Originally Posted by dragnsled

Hey you think like me  Boost works better than drive pressure and limiting travel is a must.  |

Hahaha, great minds think alike then eh? I still think I'm going to be adding another gauge to the dash to keep an eye on the drive pressure

__________________

Stan

08 QCSB 4x4 stock (ish) - 68RFE parts test pig

49 Dodge 2.6 pulling project "Gold Digger"

|

|

|

|

02-18-2009, 11:45 AM

02-18-2009, 11:45 AM

|

#10

|

Name: dragnsled

Title: Banned

Status: Not Here

Join Date: Feb 2009

Member`s Gallery

Posts: 262

|

Quote:

Originally Posted by BlackSkyRacing

Hahaha, great minds think alike then eh? I still think I'm going to be adding another gauge to the dash to keep an eye on the drive pressure  |

I used a piece of steel brake line coiled a few times to keep heat out of the plastic boost hose and gauge.

|

|

|

|

02-18-2009, 12:10 PM

02-18-2009, 12:10 PM

|

#11

|

Name: BlackSkyRacing

Title: Living Under a Rock

Status: Not Here

Join Date: Mar 2007

Location: Sparta, WI

Member`s Gallery

Posts: 1,394

|

Quote:

Originally Posted by dragnsled

I used a piece of steel brake line coiled a few times to keep heat out of the plastic boost hose and gauge. |

I was under the impression that 10ft of copper tubing would work??? Can't remember where, I think in the March Diesel Power they showed a drive pressure gauge install...

__________________

Stan

08 QCSB 4x4 stock (ish) - 68RFE parts test pig

49 Dodge 2.6 pulling project "Gold Digger"

|

|

|

|

02-18-2009, 02:54 PM

02-18-2009, 02:54 PM

|

#12

|

Name: dragnsled

Title: Banned

Status: Not Here

Join Date: Feb 2009

Member`s Gallery

Posts: 262

|

Quote:

Originally Posted by BlackSkyRacing

I was under the impression that 10ft of copper tubing would work??? Can't remember where, I think in the March Diesel Power they showed a drive pressure gauge install...

|

You should be fine.I only used steel cause it was cheap and I already had a piece at the shop at midnight.

|

|

|

|

02-18-2009, 03:10 PM

02-18-2009, 03:10 PM

|

#13

|

Name: BlackSkyRacing

Title: Living Under a Rock

Status: Not Here

Join Date: Mar 2007

Location: Sparta, WI

Member`s Gallery

Posts: 1,394

|

Quote:

Originally Posted by dragnsled

You should be fine.I only used steel cause it was cheap and I already had a piece at the shop at midnight.   |

I know how that goes... 30 miles from the nearest town with anything to speak of for supplies. Our shop is so cluttered with stuff because "we may need that someday". Funny part is only about 10% of that stuff will ever get used  My dad's a pack rat...

__________________

Stan

08 QCSB 4x4 stock (ish) - 68RFE parts test pig

49 Dodge 2.6 pulling project "Gold Digger"

|

|

|

|

08-03-2009, 10:06 AM

08-03-2009, 10:06 AM

|

#14

|

Name: CSM diesel

Title: Engineer

Status: Not Here

Join Date: Jun 2007

Location: Golden, CO

Member`s Gallery

Posts: 479

|

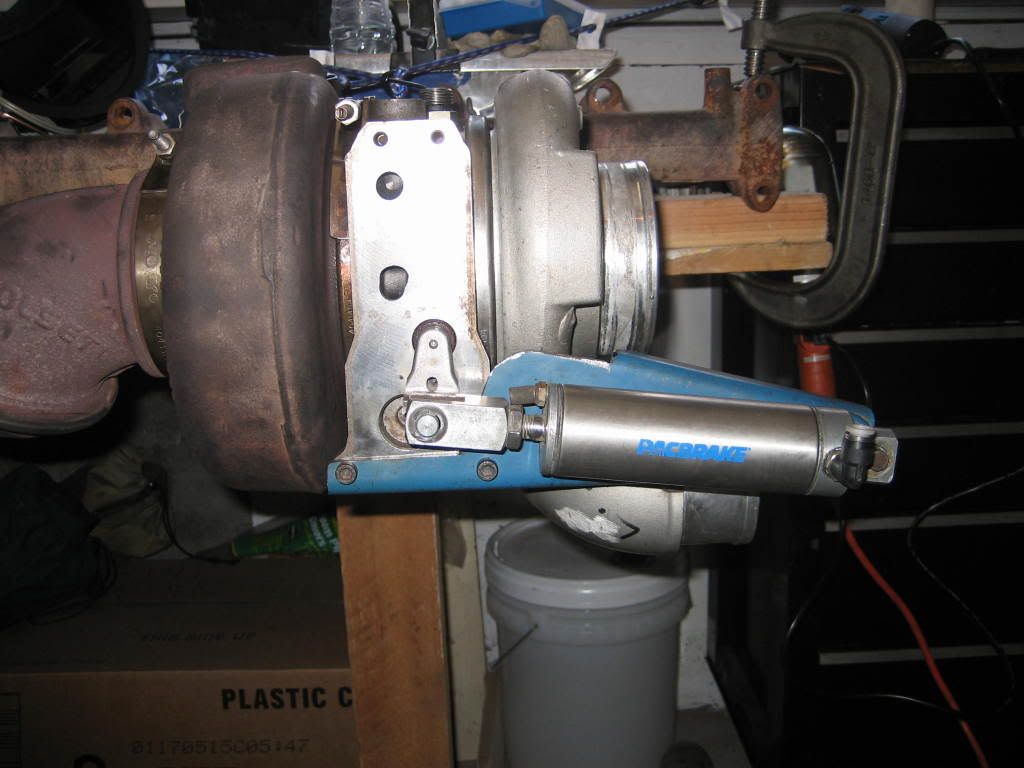

Back from the DEAD!

It has been a long time since I have made any progress worth noting on this little endeavor.

Here it is on the manifold...

And with the actuator...

And again...

And yet again...

And finally, on the truck...

I have chosen to flip the manifold and mount the turbo as high as possible, I am "going for broke" with this and will be hanging a K31 under it eventually.

I will be hopefully building the exhaust for it this weekend. The discharge pipe is done and the factory intake hooks up to it as well.

__________________

1998 Dodge Ram 2500, 12 valve

|

|

|

|

08-03-2009, 02:56 PM

08-03-2009, 02:56 PM

|

#15

|

Name: lorendiesel5.9

Title: OG Hunnybadger

Status: Not Here

Join Date: Apr 2009

Location: NE IA or the lower 48

Member`s Gallery

Posts: 3,909

|

Why are you going with the he351 ? IMO you won't gain anything cause your not moving more air on the top end over the stock turbo.

__________________

Rest in Peace Dex aka BFD99 6/2/12

97 #12vqclbmafia slipping auto

00 Pete 378 12.7 Detroit 10spd

03 Pete 379 6NZ Caterpillar 18spd

|

|

|

|

08-03-2009, 02:59 PM

08-03-2009, 02:59 PM

|

#16

|

Name: CSM diesel

Title: Engineer

Status: Not Here

Join Date: Jun 2007

Location: Golden, CO

Member`s Gallery

Posts: 479

|

It is a 60mm turbo. It will move more air than a "stocker." Plus, I live and drive at elevation (6k - 11k feet) and spool-up is my primary concern.

__________________

1998 Dodge Ram 2500, 12 valve

|

|

|

|

08-03-2009, 03:24 PM

08-03-2009, 03:24 PM

|

#17

|

Name: BlackSkyRacing

Title: Living Under a Rock

Status: Not Here

Join Date: Mar 2007

Location: Sparta, WI

Member`s Gallery

Posts: 1,394

|

You will have to let me know how that works for you... I know my 451 using boost to control the housing was a pooch in Colorado Springs at about 6k'. I think for my set up using drive pressure might make it a little less finicky about elevation. But yours having a smaller housing and a more tunable set up should work quite well. I will tell you this VGT stuff is fun, it makes massive low end torque. But I too am definitely considering a K31 or a HT3B

EDIT: Strange enough, my truck ran better going up the Mountain on Gold Camp Road then in town

On a side note, it's not cool when you are working outside and the sirens at NORAD start going off

__________________

Stan

08 QCSB 4x4 stock (ish) - 68RFE parts test pig

49 Dodge 2.6 pulling project "Gold Digger"

|

|

|

|

08-03-2009, 03:37 PM

08-03-2009, 03:37 PM

|

#18

|

Name: CSM diesel

Title: Engineer

Status: Not Here

Join Date: Jun 2007

Location: Golden, CO

Member`s Gallery

Posts: 479

|

I just drove up and over Loveland and Vail passes this weekend. Touched 1200deg a time or two with the hx35 and my fueling.

The rub is going to be finding where to switch over from dive pressure to boost pressure control. Staying at 1:1 boost to drive ratio is paramount.

__________________

1998 Dodge Ram 2500, 12 valve

|

|

|

|

08-03-2009, 03:39 PM

08-03-2009, 03:39 PM

|

#19

|

Name: CSM diesel

Title: Engineer

Status: Not Here

Join Date: Jun 2007

Location: Golden, CO

Member`s Gallery

Posts: 479

|

Quote:

Originally Posted by BlackSkyRacing

You will have to let me know how that works for you... I know my 451 using boost to control the housing was a pooch in Colorado Springs at about 6k'. I think for my set up using drive pressure might make it a little less finicky about elevation. But yours having a smaller housing and a more tunable set up should work quite well. I will tell you this VGT stuff is fun, it makes massive low end torque. But I too am definitely considering a K31 or a HT3B

EDIT: Strange enough, my truck ran better going up the Mountain on Gold Camp Road then in town

On a side note, it's not cool when you are working outside and the sirens at NORAD start going off  |

I live at 6k feet. How big are the wheels on the 451? The 351 is 60/60/VGT IIRC.

__________________

1998 Dodge Ram 2500, 12 valve

|

|

|

|

08-03-2009, 08:11 PM

08-03-2009, 08:11 PM

|

#20

|

Name: Trapper

Title: Hater

Status: Not Here

Join Date: Aug 2006

Location: Arizona

Member`s Gallery

Posts: 2,878

|

Can you post a pic of your recent set up?

__________________

Work In Progress

|

|

|

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is Off

|

|

|

All times are GMT -5. The time now is 10:31 PM.

|