You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Head Gasket Compressed Thickness

- Thread starter 1972RedNeck

- Start date

1972RedNeck

New member

Lemme get this straight, you put this engine together and can't CC the pistons, and didn't check piston to valve clearance? I wouldn't go off the calculator on Hamilton's website with all the changes you've made as far as decking the block and head.

IMO you HAVE to know those numbers when building an engine, from stock to 2000 horsepower it doesn't matter.

BTW Play-Dough works great for PTV clearance. Probably could use it to CC the pistons as well

Pretty pathetic, right? I could CC the pistons, and have many times, I just didn't take the time to. I'm a top-notch farmer and am meticulous with my soil health, soil fertility, irrigation, etc. Engine builder? Not so much. Just a rip and tear and get it done kind of mechanic. I have learned with mechanical moving parts, far enough tends to be better than close enough.

As for piston to valve clearance, if Hamilton's calculator said I was good, I was comfortable running it as I knew that they have some safety built into it and I had an extra almost .010" according to their calculator.

I finally got it up and running. Broke the cam in and then ran the wheels off of it and changed the oil.

It is running great. The timing is set similar to before the rebuild and the fuel setting and injectors are the same. So the only things that have changed are the 178/208 Hamilton cam and slightly higher compression due to shaving .010" off the block (whatever this increase comes out to be).

With the old engine, I didn't have the AFC tuned very well and it would lay out some thick black smoke before the turbo came on board.

Now, the turbo comes on board 300 to 400 RPM sooner and there is only a grey haze when I punch it. Way more low-end torque. I can lug it down to 700 RPM and punch it and the turbo starts building boost right away. The cam was definitely money well spent.

The best part is, it hasn't self destructed from piston to valve interference yet. Far enough for me.

And for the record, I finally heard back from the vendor who contacted Mahle. This head gasket is supposed to be .062" compressed. According to my super accurate chinese feeler gauges, it feels closer .060" right now.

since you and I are after the same thing, high compression VE motor, and happen to be running the same cam, I sent an email off to hamilton to see what their thoughts are on minimum piston to valve. cheers

Standard Mahle headgasket, .037" piston protrusion, .045" valve face depth with the 178/208 cam works with no apparent issues. Your mileage may vary.

If I would have had to bore it .020 and buy pistons, I would have got the 18.5:1 naturally aspirated pistons and left everything else the same.

Not sure if it is the slight increase in compression or the cam, but either way, I am sold on this combo for driveability and low-end torque. If I can get up to 15 or 16 MPG from my previous 14 MPG, I will be ecstatic. Not really holding my breath, though.

Last edited:

1972RedNeck

New member

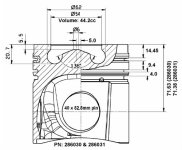

Calculating compression and piston design is part of what I do, using same piston and only increasing protrusion 0.010" you would need to reduce chamber volume 2cc's to get just over 18:1, which I find unlikely.

View attachment 73870

Would you happen to have the print for an 18.5:1 NA piston?