biggy238

Active member

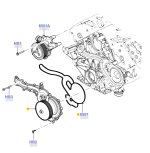

My wife's brother in law just picked up a SCSB with 207k and it's bleeding to death from something above the crank. It looks to me from Google images that it's likely the vacuum pump.

How much time are we talking to access this thing, is it a throw away and get a new one or reseal it and reinstall?

I'm assuming it's not ruptured and the threads that attach it aren't damaged.

Truck has a level/lift and I didn't feel like climbing to really inspect it. I'm thinking about getting my bore scope and feeding down in there tomorrow after work.

Sent from my motorola one 5G using Tapatalk

How much time are we talking to access this thing, is it a throw away and get a new one or reseal it and reinstall?

I'm assuming it's not ruptured and the threads that attach it aren't damaged.

Truck has a level/lift and I didn't feel like climbing to really inspect it. I'm thinking about getting my bore scope and feeding down in there tomorrow after work.

Sent from my motorola one 5G using Tapatalk