You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

I'm stumped! No oil pressure

- Thread starter BC847

- Start date

jimbo486

New member

My first thoughts were similar to what Will said about comparing the cover plate to the oil filter head to see if the passages are any different.

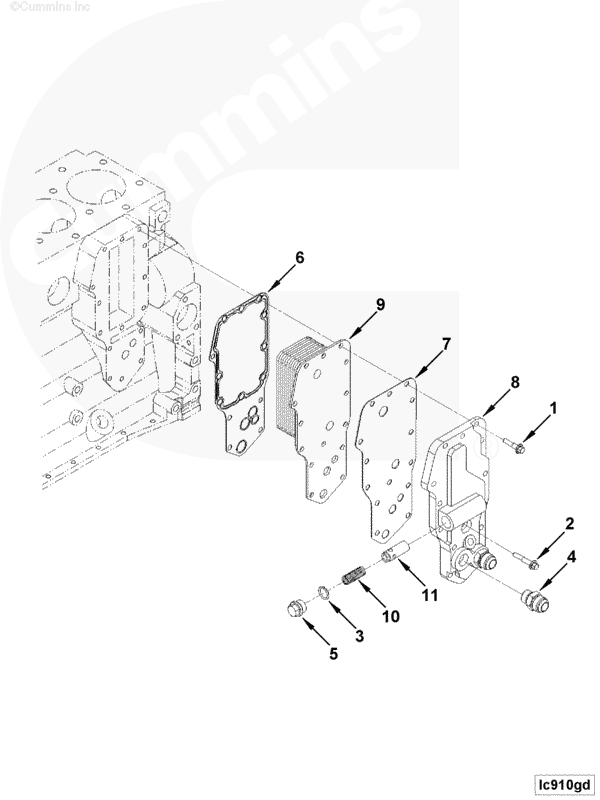

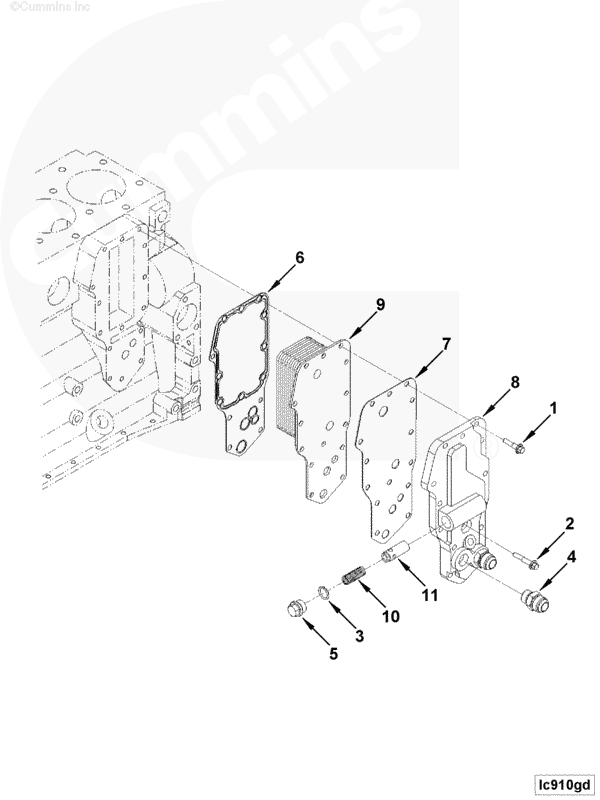

You've probably compared the gaskets and part numbers or Jeff's done so already but I attached a screen shot from QuickServe for my engine. The gaskets appear to be the same based on the images.

Is there anything inside or behind the supply port in the cover plate that would prevent feed to the turbo(s)? I imagine it's not a blind hole that requires drilling and tapping. Surely you'd have caught that. Still strange that the gauge registers pressure when cranking but not running.

You've probably compared the gaskets and part numbers or Jeff's done so already but I attached a screen shot from QuickServe for my engine. The gaskets appear to be the same based on the images.

Is there anything inside or behind the supply port in the cover plate that would prevent feed to the turbo(s)? I imagine it's not a blind hole that requires drilling and tapping. Surely you'd have caught that. Still strange that the gauge registers pressure when cranking but not running.

Attachments

Last edited:

jimbo486

New member

Try shimming the spring on the regulator. Im betting its opening up. Also put a mechanical gauge on so you can see if this helps.

Referencing part numbers between the cover plate and filter head, the pressure regulator spring returns the same number but others show as well.

Last edited:

BC847

New member

Folks, I appreciate y'all thinking about this with me.

jimbo486, I suppose you've found as I, there's not a lot of info out there about this filter relocation plate.

biggy238, Yes, the oil pressure regulator piston is shown backwards as hell in the Cummins photo. That pic of the filter relocation plate is shown minus the oil pressure regulator. It's purchased separately.

I found an article about the Cummins engine written by Roy Berndt that sheds some light on the oil system and coolers. It includes:

In talking with Snedge, I should be using that gasket shown as A (from a STORM block).

I've still got to pull the turbos so as to get to the thing and compare the storm gasket to the OEM (B) gasket. The STORM gasket should be here by Friday. (I hope).

jimbo486, I suppose you've found as I, there's not a lot of info out there about this filter relocation plate.

biggy238, Yes, the oil pressure regulator piston is shown backwards as hell in the Cummins photo. That pic of the filter relocation plate is shown minus the oil pressure regulator. It's purchased separately.

I found an article about the Cummins engine written by Roy Berndt that sheds some light on the oil system and coolers. It includes:

Covers and Coolers

The B series engine could experience high oil pressure spikes on cold start up (up to 130 PSI), especially in low ambient temperatures. The original design would take oil bypassed by the oil pressure regulator and route it to the oil pump inlet (dump to pump). To correct this, use an oil cooler, oil cooler cover and oil cooler gasket that takes the oil bypassed by the regulator and routes it into the oil pan (dump to sump).

Oil coolers and gaskets can give you fits if used in the wrong combination, with either extremely high or low oil pressure, when used in the incorrect combinations.

Cooler #1 is used as follows: Coolers with four-passage drillings have drillings at both the dump-to-sump and dump-to-pump locations. These are not to be used on the ISB (STORM) blocks and are no longer produced for production or service.

Cooler #2 is used as follows: Coolers with three-passage drillings designed for dump-to-sump lubricating systems can be used in a STORM or pre-STORM block if the engine uses a dump-to-sump oil system.

Cooler #3 is used as follows: Coolers with 3-passage drillings designed for dump-to-pump lubricating systems can only be used on STORM or pre-STORM blocks with a dump-to-pump oil system.

Gasket #1 is for a STORM Block and can be easily identified by the “window” and slot in it.

Gasket #2 is for a Pre-STORM Block. The cylinder block, oil cooler, oil cooler gasket and oil cooler cover must be matched up correctly. If not done correctly, high oil pressure or low oil pressure will be experienced.

In talking with Snedge, I should be using that gasket shown as A (from a STORM block).

I've still got to pull the turbos so as to get to the thing and compare the storm gasket to the OEM (B) gasket. The STORM gasket should be here by Friday. (I hope).

Last edited:

BC847

New member

Yes. That shown as cooler #2. In the stock/OEM form, that cooler works in my heap with gasket B.Are you still using the factory oil cooler in the block?

Last edited:

Financial Mistake

New member

Not to derail, but whose triple kit is that? And what turbos??

Sent from my iPhone using Tapatalk

Sent from my iPhone using Tapatalk

Mooner1

New member

I've been keeping up with BC's sweet tripe build on 1stgen.org. He built it himself and they are 62mm borg sxe's I believe. I can never get logged in over there for some reason but I have been checking on his progress daily for a long time. Sweet as hell I think and can't wait to see how 'ol mean green runs once he gets it all buttoned up!

Financial Mistake

New member

That's a super clean setup for being home brewed. I'm impressed.

Sent from my iPhone using Tapatalk

Sent from my iPhone using Tapatalk

12vCumminsFTW

Active member

I've been keeping up with BC's sweet tripe build on 1stgen.org. He built it himself and they are 62mm borg sxe's I believe. I can never get logged in over there for some reason but I have been checking on his progress daily for a long time. Sweet as hell I think and can't wait to see how 'ol mean green runs once he gets it all buttoned up!

Link? I love triple builds lol.

Hope you figure out the oil issue. Cant wait to see how it runs.

BC847

New member

It happens. Keep going forward! :Cheer:

BC847

New member

When I fabricated and installed the remote engine lube-oil filter bracket and filter-head, I bet I spent a good cumulative hour studying the filter lines exclusively. Confirming the Asian fella's idea of the English In/Out and which port to cast them to. Ciphering the proper dirty oil in, and clean oil out of the filter-head. All that and more is required to build a working thing. The top idea in all of this was to have the chit work and be reliable. I'm use to beating the snot out of my heap on a Thursday night, only to drive it to the coast and back the following weekend. Been doing THAT thing with a HT3B blowing into an S362 for fiveish years.

I guess there's folks out there who would have thought the gauge was wrong and drove it to disaster . . . . . .

Anyhoo . . . .

Y'all took the time to mess with me and my heap, let me return the favor . . .

My 1993 Cummins 12v block is of the "Dump to Sump" in terms of where the oil pressure regulator dumps that excess oil pressure it vents. It dumps it to the sump (oil pan). There apparently are blocks out there that "Dump to Pump" and might have issues with substantial oil pressure spikes as a result. That's why there's two or three gaskets for the 12v application of stuff. Don't quote me there as the dump to pump didn't pertain to me so . . .

Anyway, the illustration of parts for MY heap is in fact correct as show here.

My 1993 stock/OEM cooler-cover gasket works with this remote filter cooler-cover.

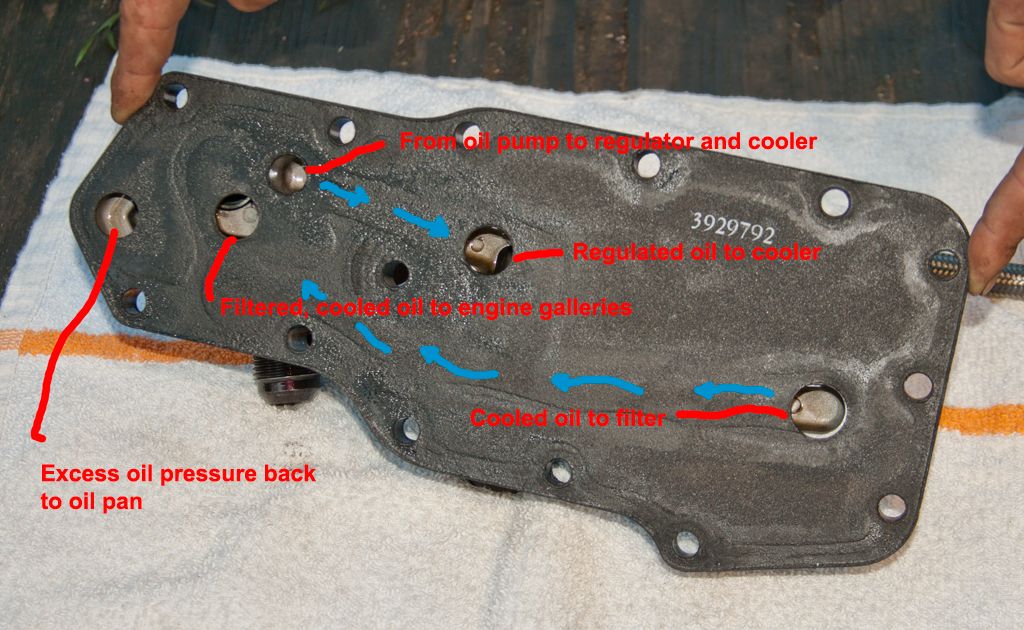

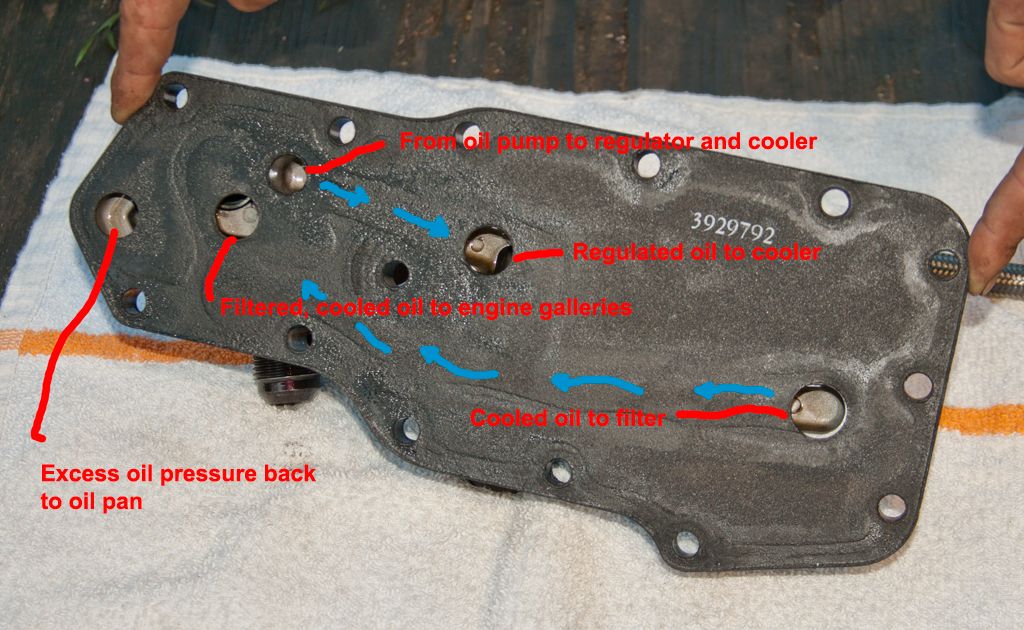

This is the block-side of the remote-filter cooler-cover:

My 1993 cover to cooler gasket fits all ports involved as shown:

(Blue is oil flow direction)

The foot-prints of the remote-filter cooler-cover passages are clearly seen and present where they should:

The STORM/Encore whatever block gasket does not work on my 1993 12v block. The gasket's extra port makes a leak in the seal of the clean/cooled oil supply to the engine passage. As such, it will dump clean/cooled oil to the regulator's drain to the pan.

I'll round up and post the part numbers that work on my heap in a short while.

Phacking oil filter's anti-drainback valve made the weird oil pressure/flow stuff. :doh:

I guess there's folks out there who would have thought the gauge was wrong and drove it to disaster . . . . . .

Anyhoo . . . .

Y'all took the time to mess with me and my heap, let me return the favor . . .

My 1993 Cummins 12v block is of the "Dump to Sump" in terms of where the oil pressure regulator dumps that excess oil pressure it vents. It dumps it to the sump (oil pan). There apparently are blocks out there that "Dump to Pump" and might have issues with substantial oil pressure spikes as a result. That's why there's two or three gaskets for the 12v application of stuff. Don't quote me there as the dump to pump didn't pertain to me so . . .

Anyway, the illustration of parts for MY heap is in fact correct as show here.

My 1993 stock/OEM cooler-cover gasket works with this remote filter cooler-cover.

This is the block-side of the remote-filter cooler-cover:

My 1993 cover to cooler gasket fits all ports involved as shown:

(Blue is oil flow direction)

The foot-prints of the remote-filter cooler-cover passages are clearly seen and present where they should:

The STORM/Encore whatever block gasket does not work on my 1993 12v block. The gasket's extra port makes a leak in the seal of the clean/cooled oil supply to the engine passage. As such, it will dump clean/cooled oil to the regulator's drain to the pan.

I'll round up and post the part numbers that work on my heap in a short while.

Phacking oil filter's anti-drainback valve made the weird oil pressure/flow stuff. :doh:

Last edited:

YOUNG GUNS15

Im AWESOME!!!!

So it's fixed?

Sent from my iPhone using Tapatalk

Sent from my iPhone using Tapatalk

Big Blue24

Comp Diesel Sponsor

I knew it was your problem, I honestly didn't have the pictures to back up the problem, thank you for taking the time to post pictures to help others who follow in your foot steps. The only other thing I'll mention is if you use the early style gasket that does not have the cut out, it will hold pressure, but it scares me to have oil pushing against the gasket that is unsupported on the backside, so we drill, tap, and plug that small hole (return to pump) on storm blocks when using the early style cooler/filter head.

The only way to learn about this problem is to make the mistake, scratch your head for a day or two, and then dig in and follow the oil flow passages from oil pickup tube to main oil galleys in the block.

Glad you found your problem. I was a bit worried about your slow crank oil pressure, that one stumped me so I wasn't too assertive about the cooler/filter head/gasket differences, but the filter internal bypass makes sense, so I learned something from this as well.

Once again, thanks for posting pictures and fairly detailed explanation of the oil flow, I'll bet it helps out many more "hotrodders" in the future.

The only way to learn about this problem is to make the mistake, scratch your head for a day or two, and then dig in and follow the oil flow passages from oil pickup tube to main oil galleys in the block.

Glad you found your problem. I was a bit worried about your slow crank oil pressure, that one stumped me so I wasn't too assertive about the cooler/filter head/gasket differences, but the filter internal bypass makes sense, so I learned something from this as well.

Once again, thanks for posting pictures and fairly detailed explanation of the oil flow, I'll bet it helps out many more "hotrodders" in the future.