Jacob 76

Let'er Buck

Are they practical for street use at all or one of those competition only things?

What he said

Are they practical for street use at all or one of those competition only things?

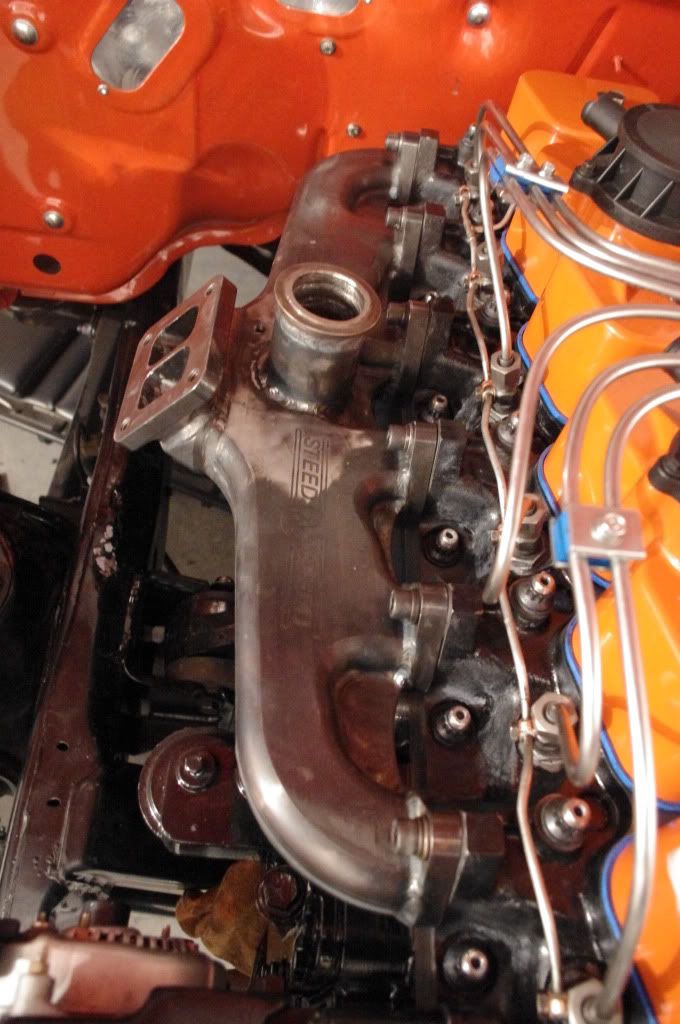

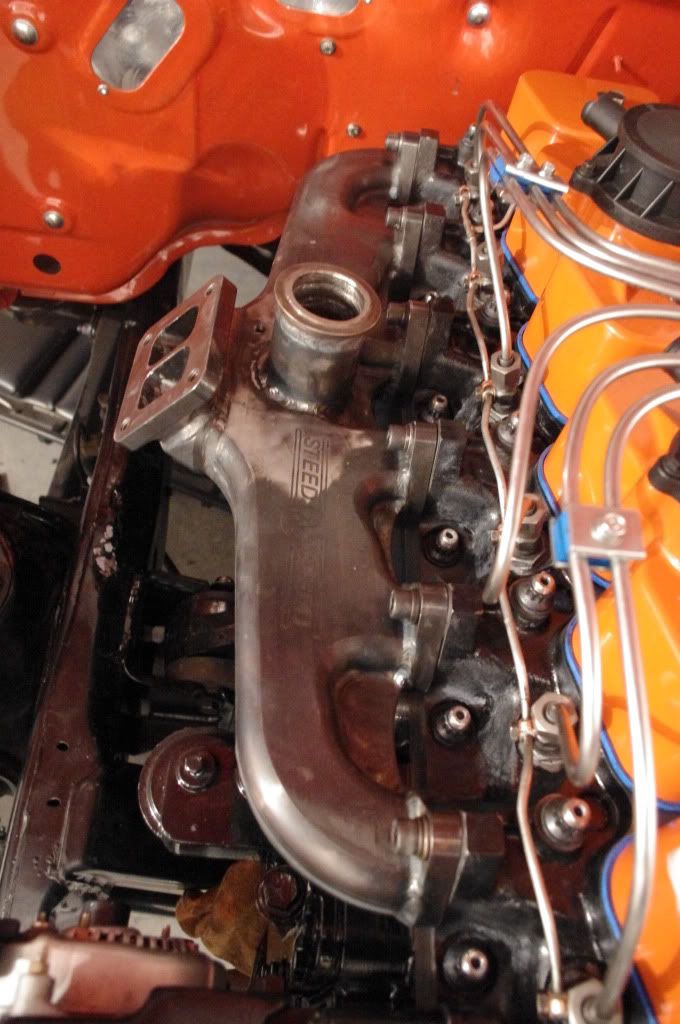

I got mine yesterday!

I got mine yesterday!

You are going to love the manifold. In testing the manifold scavenges on every cylinder. In other words, exhaust coming from any of the ports will create a major vacuum in the other two adjacent passages. Velocity at the flange is very high as all of the exhaust energy is getting to the turbo. Expect very good results!

BTW, Make sure you don't over torque the head bolts. You have to let the manifold grow and shrink independent of the head. You should get the manifold coated too. I'll be happy to do that no charge if you wish.

You are going to love the manifold. In testing the manifold scavenges on every cylinder. In other words, exhaust coming from any of the ports will create a major vacuum in the other two adjacent passages. Velocity at the flange is very high as all of the exhaust energy is getting to the turbo. Expect very good results!

How does it scavenge when that entire area is under some level of drive pressure? I can mentally picture scavenging in an open-header type of situation, where atmospheric pressure is only present... but above that, I'm not seeing it.

What torque do you suggest to the head? Factory Stec ??

It scavenges because the exhaust pulses are traveling at a high rate of speed and as they pass the point where they meet the other passages they suck the gas out of the other passge in the same way an air brush sucks paint up to the top of the feed tube. I have tested the manifolds with a leaf blower and if you blow into any of the ports the other ports will suck a sheet of cardboard up against them and hold them there due to the vacuum created by the high speed air going through the other passage. This effect is seen on every cylinder on this manifold. You don't really want to use "pressure" to drive the turbo but rather you need to harness the kinetic energy of the fast moving exhaust.

Let me ask a related, rhetorical question.... if you block the outlet of the manifold and any combination of the other ports to actually read gauge pressure, how can you then measure scavenging? (obviously not with a leaf blower and cardboard)

I'm a good ol' boy that does make do with limited tools in my garage - however, a claim that a turbo manifold scavenges simply from a 'blow-through' test at atmospheric pressure is absurd to me, and one that I would be wary of trying to stand behind if I were making the product.

It is obvious that the new design is an improvement over the previous iteration, stretching the turns out & whatnot are always improvements in stagnation and flow losses.

Let me ask a related, rhetorical question.... if you block the outlet of the manifold and any combination of the other ports to actually read gauge pressure, how can you then measure scavenging? (obviously not with a leaf blower and cardboard)

I'm a good ol' boy that does make do with limited tools in my garage - however, a claim that a turbo manifold scavenges simply from a 'blow-through' test at atmospheric pressure is absurd to me, and one that I would be wary of trying to stand behind if I were making the product.

It is obvious that the new design is an improvement over the previous iteration, stretching the turns out & whatnot are always improvements in stagnation and flow losses.

Dyno and race results are going to say all that you need to know about my methods. The manifolds can speak for themselves from here on.