Episode 11

NOTE: Due to the limitations on the number of photos I can post on many forums, I will post a more detailed version with more photos on the

newly updated ISSPRO Website:

Please check it out over there!

Sorry for the lull in updates. Usually the gatherings of my extended family occur at my dad's house, but he was on a 3-month cruise with my aunt and uncle, so it fell to me to host those kind of gatherings. I hadn't done much housekeeping since hurting my back in December, as any "spare" time was spent on the race truck. I had LOTS of housecleaning to do before the Easter gathering. After that I went into prep mode for a child custody hearing. My attorney lets me do most of the prep work for trial so it costs me less money, but it means a significant amount of time. Immediately after that was our family Mother's Day gathering. Somewhere in there I de-winterized my gasser race car and my daughter's Jr Dragster, as we finally got in a local race without raining out.

We traveled down to Redding, CA for the Jefferson State Diesel Nationals, where I went to the 3rd round in my dually, and lost with a decent light while running on my dial-in, as the other guy had an even better light and ran on HIS dial-in!

Two weeks later we headed to Mission, BC for the BD Diesel Nationals. That race was a little less successful, as I red-lit by 0.008, and managed to do it to someone who forgot to put his truck in 4x4 and cut a 0.476 light and ran 2+ seconds off his dial-in. It was a little less painful to lose the good race in Redding!

In my Vega I have been sorting out some issues, after doing some datalogging I figured out that one source of inconsistency was my torque converter.

After replacing it with a custom built unit from Hughes Performance, I won two races in a row, then took 2nd in the consolation bracket the next week (went out first round of the regular class when the other guy had a 0.008 light and ran 0.010 off his dial, while I cut a horrible light partially due to sun glare). Note to self - when everyone is lining up in the right lane, walk around the corner and see if the sun is glaring in the eyes of the left lane racers!

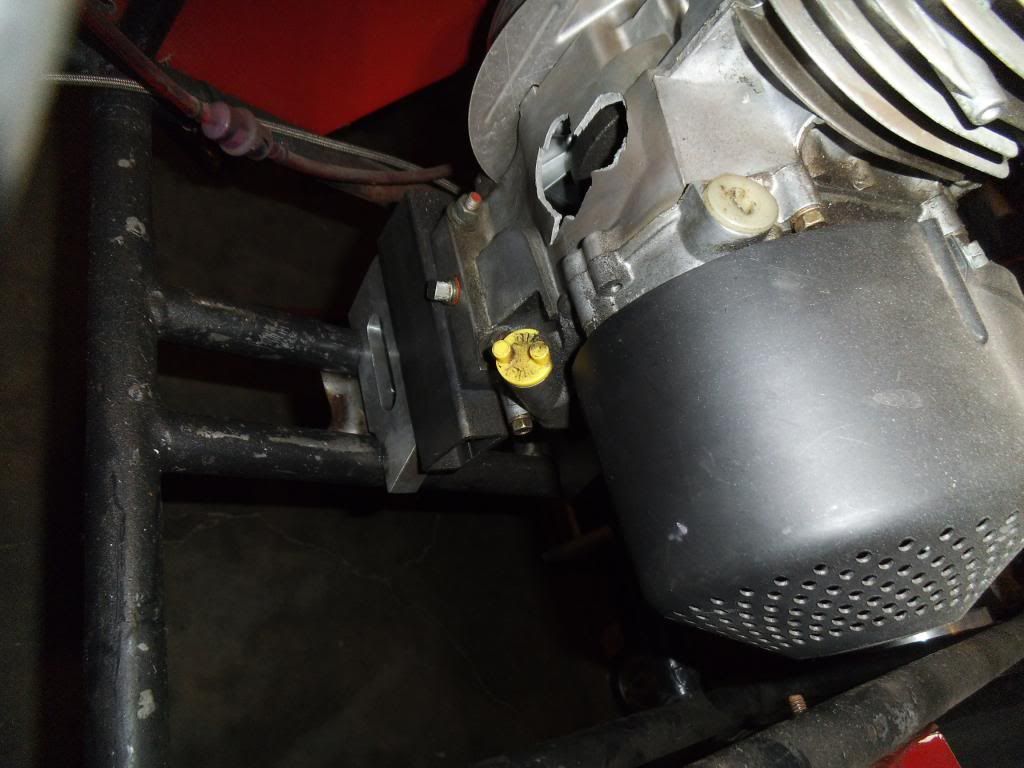

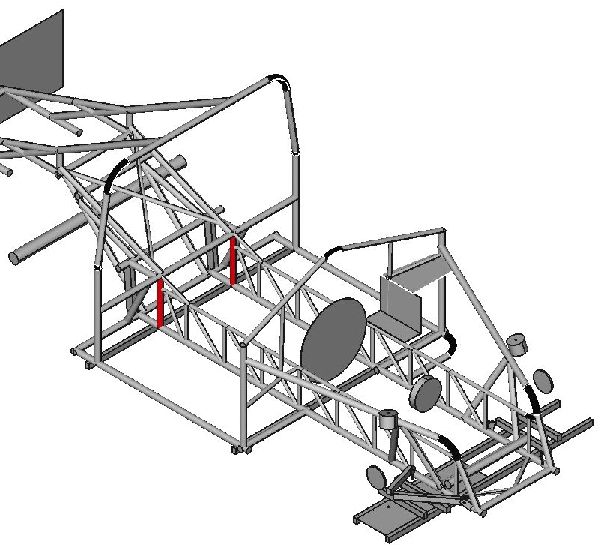

I updated the rendering of the truck to represent the altered wheelbase. I wanted to see how goofy it looks. I'm a bit biased but I kinda like it!

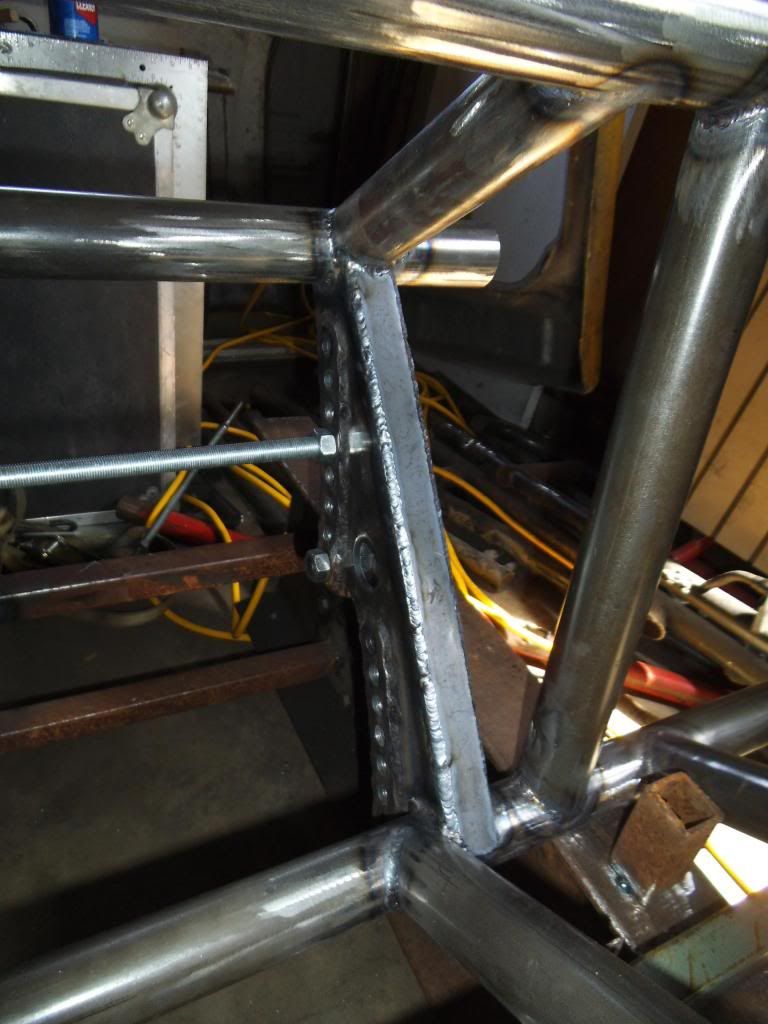

Despite the aforementioned items taking up my time, I still managed to keep working steadily (if not slowly) on the race truck. As we last left off I was basically starting the chassis over. With the help of my friend Duane Merritt and his chassis shop, we bent up some new bars. It was nice to start from scratch and make a few changes in the design of the chassis. A key part was the way the main hoop ties into the floor area and main crossmember. With this change I could get less likelihood of the main hoop collapsing, without resorting to gussets which can cause a stress concentration.

Just to help understand some of the decisions I have made on this chassis, here is a quick Structural Engineering 101:

When it comes to structural strength, bigger is NOT always better. In many cases you can make a part STRONGER (able to carry more load without failure) by REMOVING material. As counter-intuitive as this sounds, let me see if I can explain in a way that makes sense.

Metal fails when the load causes a stress level beyond its limit at that specific location. If a bar is undergoing a bending load, that bar will deflect proportinally to the load. However, if one section of that bar is "reinforced" such that it has much less deflection, the section adjacent to it will have substantially MORE localized deflection than without that reinforcement, as it is now the weak point with higher stress. This extra deflection is effectively a "stress riser", or a spot with increased stress, and a likely point of failure. If you remove some of that reinforcement such that the whole bar "distributes" the deflection evenly, the peak stress level will decrease. Basically you want to avoid drastic changes in cross section.

To save you from going back a few pages, this is what the main hoop used to look like:

With the old layout the main hoop did not tie directly to the outermost frame rails, so I would have needed extra tubes running there, forming a joint that is not as strong as it could be, and with some stress concentrations.

I removed the old main hoop and the right side roof/pillar bar, leaving almost nothing of the original chassis (and even more of that in the photo will be removed by the time this is completed). I left a lot of the floor in place so I had something to stand on when welding towards the top!

Now a quick tip - when using a tubing notcher, be damn sure that A) the tubing is well secured, and B) the hole saw shaft support is close to the saw itself, so flex does not allow it to move significantly. Here is a shot of me violating both of those rules, trying to cut at an angle the notcher would not otherwise work on:

And this was the result:

Yup, those teeth did not survive the rocking of the hole saw!

I am on my 3rd hole saw, the 1st 2 lasted about 4 notches total. The 3rd one is still going strong after about 16 notches. I also use wax cutting lubricant instead of cutting oil, it seems to stay in place better.

As you can see in this photo, sometimes you have to get a little redneck in supporting the workpiece while working alone.

The redneck steps also include holding the main hoop with a ratchet strap while I tack welded it into place.

Next up was notching and welding in the new roof-pillar bar on the passenger side.

The door bars were next, which run from the main hoop at shoulder level down to the pillar bars down at the floor. These were relatively simple to notch, especially once I figured out some of the idiosyncracies of my new notching tool.

This photo was taken while mocking up with the old main hoop, so it shows another angle of the old main hoop.

You can see here where I added a bend to give me a little more space with the driver's side door bar. I figure space between the cage and the door is wasted space, I'd rather have that space to be more comfortable, and to allow me to leave more space for the engine and trans towards the center of the truck.

Here is the passenger door bar installed:

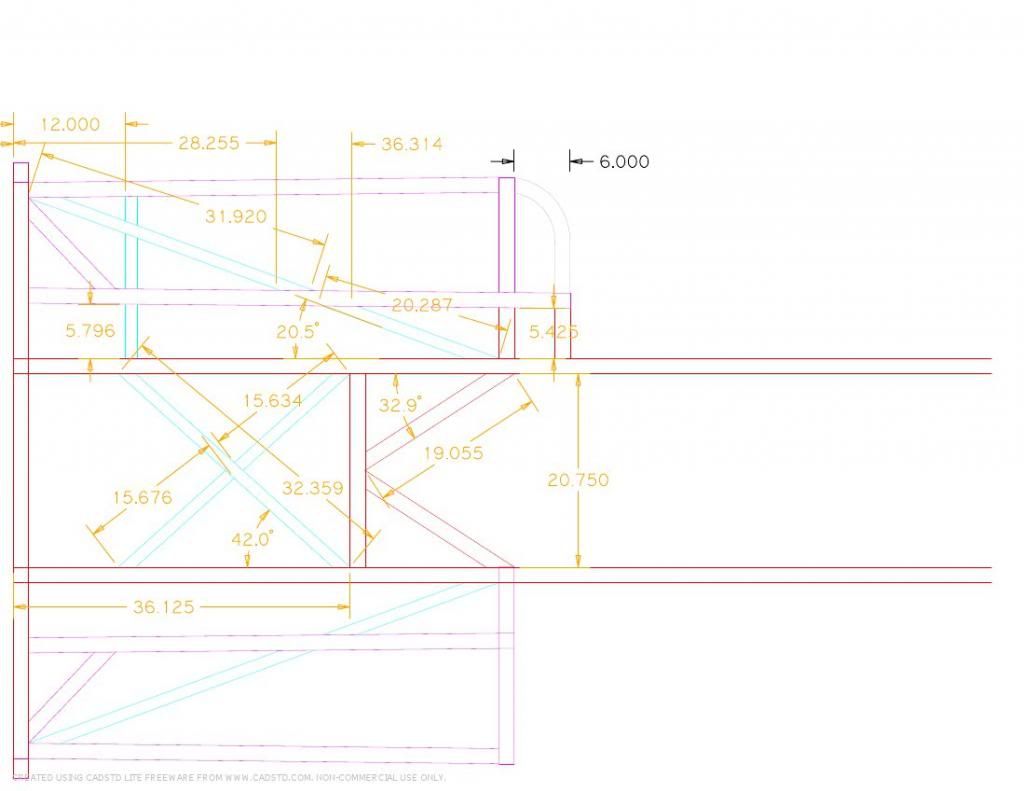

The X-bars in the door opening (lower rear to upper front) are divided up at the intersection with the door bars. This was a little tricky to notch, as the angles were beyond the capabilities of the notching tool. I did them by hand with grinding tools, a time consuming and frustrating task!

Duct tape is your friend when gravity doesn't help hold bars in place for welding!

I notched the top portions of these bars, but did not tack weld them yet since I would be climbing in and out of the cab area for all of the funny car cage construction.

When I laid out my tubes for the funny car cage, I made the mistake of not mocking up the driver's seat properly, and had to revise the tubes accordingly. The main hoop angles in quite a bit towards the top, to follow the contour of the cab, and the tube that runs behind and to the left of my helmet ends up intersecting in the bend of the main hoop instead of at the top/horizontal portion. This ended up being a major pain to notch the tube, as it had a weird angle and was also tying in to where the pillar bar intersected. After MANY hours and a few cuss words, I finally got it notched and tack welded into place.

Since this bar effectively blocked off access to a couple of other joints, I had to finish weld those joints first. Most chassis builders will tack the whole chassis together then work their way around slowly doing the finish welding (to avoid having the weld draw pulling the chassis out of square). Working in small sections you can avoid heating up the joint to the point of causing this, but it is a lot more time consuming!

Working in these tight spaces required using the short end cap on the TIG torch, which in turn required breaking the electrodes off fairly short. I made it a point to be even more careful of not contaminating my electrode, because the "shorty" electrodes are a pain to sharpen!

As I get more tubing in place, it becomes important to figure out the order that the next tubes will go in. For example, if you have two parallel tubes which will have another tube tying them together in the perpendicular direction, with the perpendicular tube properly notched you can't just insert it into place! If it is a snug fit you can't slide it in and rotate it perpendicular. I have tried to "think ahead" and not paint myself into a proverbial corner, but managed to do it on one pair of tubes. If you look at the parallel tubes in the photo above, I needed to get a cross-tube between them!

This was also a VERY important tube, as it's the one my harness will wrap around securing me into the car. The seat-back brace will also tie into this tube. I decided to make this tube larger and thicker than the minimum requirements because of this. I did NOT want to have any gaps in the mating joints, so I needed to spread the vertical tubes out and insert a properly fitted cross tube.

Building a chassis is inherently a redneck exercise, given the use of ratchet straps, duct tape and welders, and stuff is usually sitting with the wheels off and blocked in the air!

I'm getting closer to having the necessary tubes for the SFI certification of the chassis. I really want to get it certified before I reinstall the body and start doing the tinwork, both for the ease of inspecting it and in case I overlooked a tube!

Next up I will be adding the remaining tubes for the FC cage area, then the new bent dash bar, then a roof x-brace, then the floor with its crossmembes and x-braces. After that about 10 small gussets go in. Even though they are just short pieces of tubing, they take every bit as long to notch and install as a longer piece! With those parts in I can get the chassis certified.

I've also obtained most of the remaining components for the build, except for the engine rotating assembly. I'll take some photos of those parts and post them in an upcoming installment.