Cummins9912v

New member

Hey guys I'm getting ready to do a pump swap over the thanksgiving weekend and am starting to get the itch on what kind of power I will make, truck will have:

Max flowed 180 pump with 5k springs, full cut dvs, .120 holders and timing set at 26*

.093 injection lines and .093 crossovers

Banks high ram intake

Arp 625s

Little head porting

110lb valve springs

Extreme duty push rods

200hp Vulcan injectors

He351 over s475 compounds

3 piece pdi manifold

150 fass that will be set at 60psi

Nv4500 with kennys 4000 dual disk

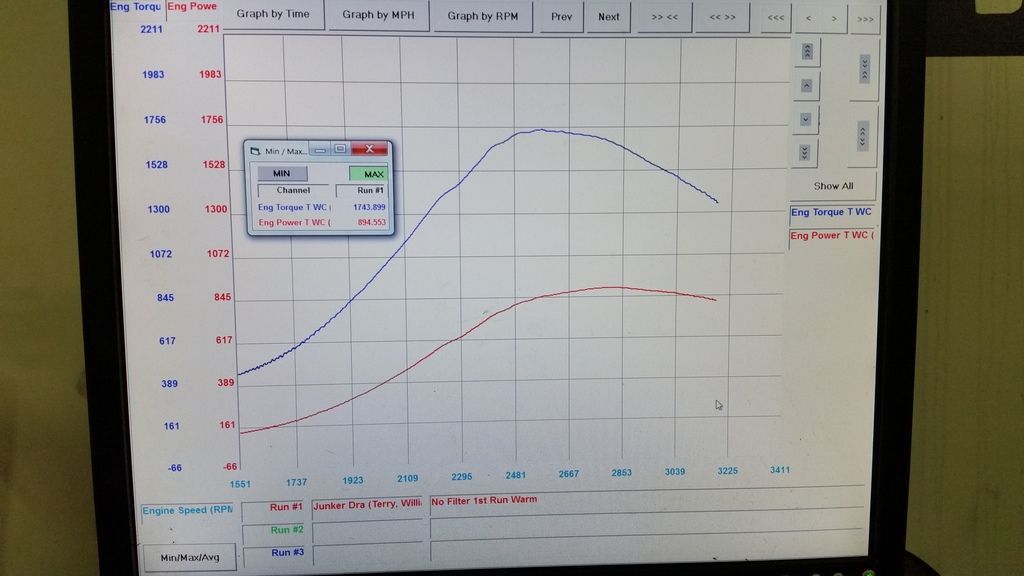

Truck made 623hp with the VP and edge juice with attitude. Thanks!

Max flowed 180 pump with 5k springs, full cut dvs, .120 holders and timing set at 26*

.093 injection lines and .093 crossovers

Banks high ram intake

Arp 625s

Little head porting

110lb valve springs

Extreme duty push rods

200hp Vulcan injectors

He351 over s475 compounds

3 piece pdi manifold

150 fass that will be set at 60psi

Nv4500 with kennys 4000 dual disk

Truck made 623hp with the VP and edge juice with attitude. Thanks!