what in the hell? are all those aircraft engines? how the? i wana see a dyno graph or it didnt happen. haha

Someone translate that whole page. What language? Norwegian? Is that a language? I am going to have to check that out when I get home.

Garrett

Probably getting paid at work to post this from my D1

It is German. Google Chrome will auto translate it for you, just saying

.

What you guys aren't up on your cold war era Soviet radial diesel engines?LOL.

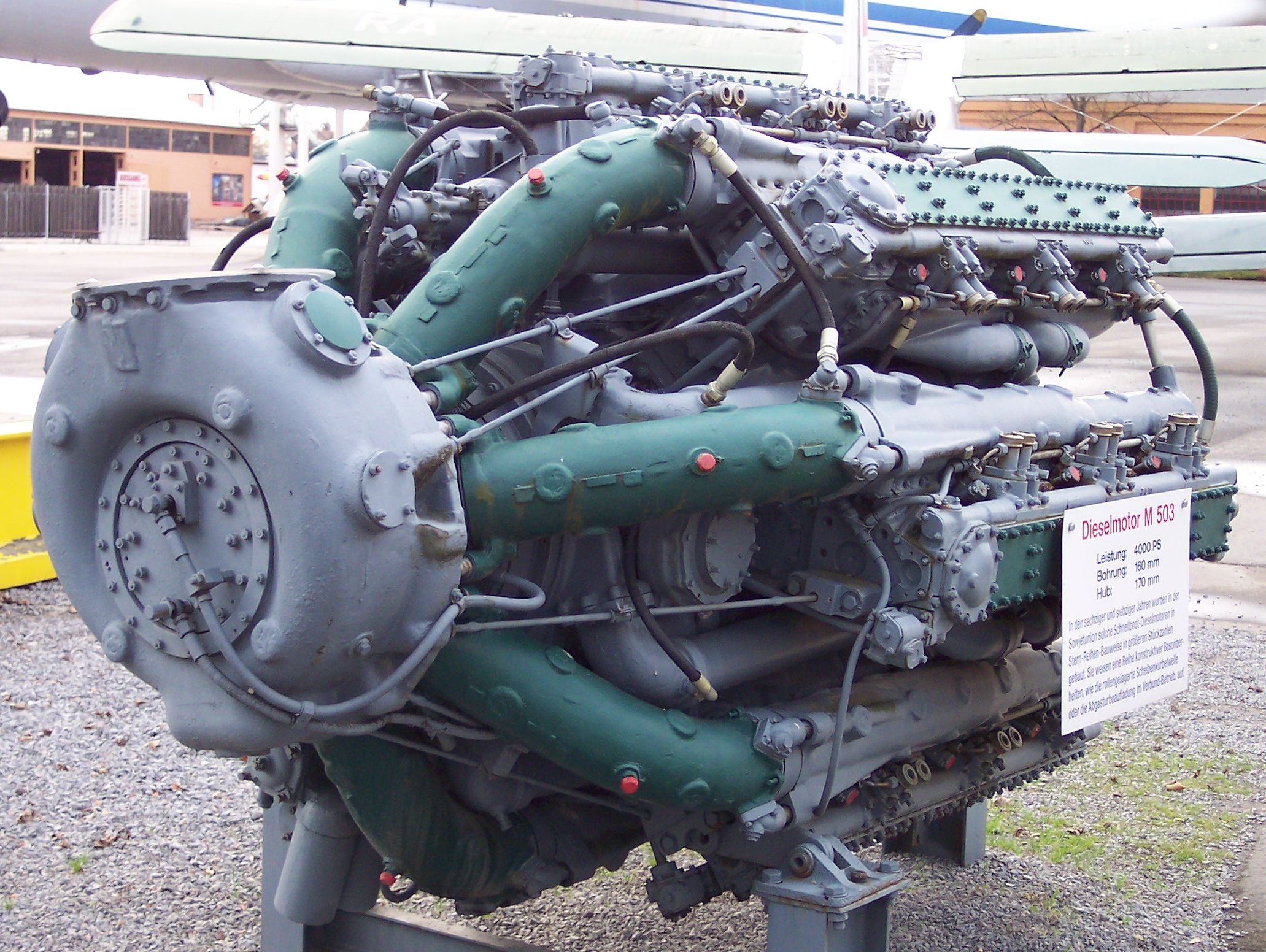

The engine in the tractor/puller I posted pics of is a highly modified Zvezda M503A marine diesel mainly used in Soviet missile boats.

Six rows of cylinders. Seven cylinders per row. 42 cylinders total. 143.6L.

General specs:

Specifications (Zvezda M503A)

General characteristics

Type: 42-cylinder Liquid cooled 6 row, 7 cylinder per row diesel radial engine

Bore: 6.29 in (160 mm)

Stroke: 6.69 in (170 mm)

Displacement: 8,763 in³ (143.6 L)

Length: 145.66 in (3,700 mm)

Diameter: 61.41 in (1,560 mm)

Dry weight: 12,015 lb (5,450 kg)

Components

Valvetrain: 7 overhead cam shafts, one per bank.

Fuel type: Diesel fuel

Cooling system: Liquid-cooled

Performance

Power output: 3,942 hp (2,940 kW, 3,997 PS) at 2,200 rpm

Specific power: 0.44 hp/in³ (20.47 kW/L)

Power-to-weight ratio: 0.32 hp/lb (0.53 kW/kg)

Then the Germans got their hands on it (this is were things get a little crazy).

The info on the this page translated:

http://www.kramp.com/info/index.php?id=2370

--------------------------------------------------------------

ZVEZDA M 503 A (DRAGON FIRE)

Zvezda M 503 A

Zvezda M 503 A

first test run

Probably the most powerful engine pulling the world

The core of the Fire Dragon is the ship's diesel engine made by Zvezda M503A in St. Petersburg. To save weight, the gear and the entire water cooling system were dismantled. The engine is run in methanol service. The methanol injection is controlled by the original diesel pump elements.

Technical data:

Engine Type: M 503A

Power: 10,000 HP

Cylinder configuration: star-shaped blocks in seven

Number of cylinders: 42

Displacement: 147.10 liters.

Compression ratio: 10.4: 1

Boost pressure: 2.1 bar

max. Speed: 2,500 rpm /

Consumption at full capacity: 4.5 ltr. per second

Number of spark plugs: 126 (3 pcs per cylinder)

Magnetzündanlagen Number: 21

Weight: 5.4 t

Here is a picture gallery of the entire renovation period.

In the following, the motor is described in its original state.

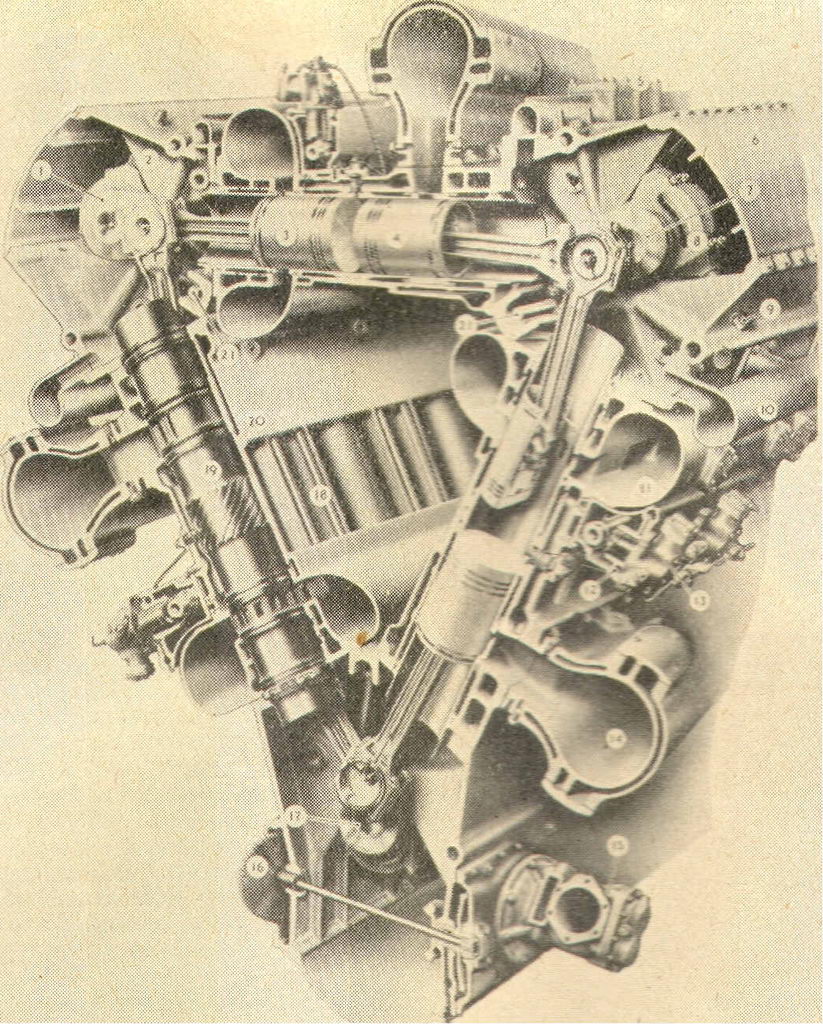

The marine diesel M 503 A is a high-speed, supercharged multi-cylinder four-stroke radial engine with water cooling. Three engines were to drive the missile speedboats (RSB) "Project 205" and the torpedo boats (TSB) "Project 206" of the People's Navy of the former GDR. These boats were delivered in the sixties by the USSR and formed about 20 years for the backbone of the "shock forces" of the People's Navy.

The cylinder block and cylinder head of the engine are cast from an aluminum alloy. In the cylinder block, the steel liners are pressed, which are sealed in the base with rubber rings. The cylinder blocks are fastened to the crankcase with tie rods that are screwed into the sections of the crankcase. The crankcase is made of seven steel sections that are joined together by bolts. The crankshaft in the crankcase runs on seven roller bearings, which locks the thrust bearing (bearing 7), the crankshaft in the axial direction.

For each star, which consists of seven cylinders, one belongs to a Pleuelgruppe Hauptpleuel and six Nebenpleueln. The Nebenpleuel are connected to the Hauptpleuel by bolts, which are pressed into the eyes of Hauptpleuels. The pistons are forged aluminum stages. Each piston is equipped with two compression rings made of steel and two oil control rings made of cast iron. The piston pins are floating.

Each cylinder head is equipped with two intake and two exhaust valves. The valves are controlled by the camshaft through rocker arms that are in the upper part of the pump block installed. The camshafts are driven by the crankshaft via a toothed gear and bevel. At the inlet channels of the cylinder block intake pipes are attached, are connected to the housing of the blower of the exhaust turbocharger connected. Along the cylinder blocks the exhaust manifolds are fitted, get out of the exhaust gases through the exhaust manifold to the exhaust gas turbocharger.

At the front flange of the crankcase of the engine, the device drive unit is attached, in which the gear train for driving the camshafts and the injection timing and the Kühlwassersammeleitung of the engine are . Two fresh water pumps are mounted on the housing of the blower. They promote the water on the bus in the transition part in the cylinder blocks.

The lubrication diagram of the motor: From the circulation tank, the lubricating oil is sucked from the pressure pump and a control filter which is housed in the units part of the engine, the main oil pipe of the engine pumped for lubrication. From the engine, the oil in the fork of one of the first and 7 Cylinder block oil sump located collector for the housing of the Umsteuerkupplung dissipated. In this special oil drain pump is pumped through the oil from the bottom two cylinder blocks and the transmission housing. From the oil sump, the oil is extracted and pumped back through a separately established oil filter and cooler in the circulation tank.

Technical data (original state):

Work designation of the motor: M 503A

Engine Type: Four-stroke diesel engine with turbocharging and Umsteuerkupplung

Cylinder configuration: star-shaped blocks in seven

Number of cylinders: 42

cylinders of the counting sequence blocks: starting from the bottom I left (as viewed from the side loader) to the right through VII,

counting sequence of cylinders: 1 to 6 (from the starting side of the turbocharger)

D cylinder bore: 160 mm

Stroke:

a) cylinder block III (Hauptpleuel): 170.00 mm

b) cylinder blocks II and IV: 174.80 mm

c) Cylinder Blocks I and V: 178.10 mm

d) Cylinder Blocks VI and VII: 171.98 mm

Displacement: 147.10 liters.

Compression ratio: 13

Rotation of the crankshaft: the left

Umsteuerkupplung: Reibungssyncronisator with rigid coupling and driving forward with planetary gearbox with reverse brake band for

Engine power at 2200 r / min: 2,940 kW (4,000 hp)

Total operating time: 600 h

Specific fuel consumption: 231 g / kWh (170g/PSh)

Injection: Einplungerpumpen, a pump for each cylinder

Injectors: Abspritzdruck 245 bar

Voreinspritzwinkel: 23 ° to 28 ° BTDC

Charge air pressure: max. 2.1 bar

Cause of the motor system: compressed air system

max. The starting air pressure: 150 bar

Dimensions of the motor (with gearbox and Umsteuerkupplung)

Length: 3,700 mm

Height: 1,560 mm

Width: 1,560 mm

Dry mass of the engine: 5,400 kg (with gear and units)

Fill in the engine cooling water: Max. 160 kg

Fill in the engine lubricating oil: max. 70 kg

--------------------------------------------------------------------------

Crazy bastards huh.

--------------------------------------------------------------------------

Rest of the page translated:

ISOTOW TV 2-117 (KIEPENKERL III)

Kiepenkerl III

Turbine Isotow TV 2-117

The Klimov TV2-117 (also Isotow TV2-117) is a turbine helicopter designed in 1964 by the Russian Klimov engine manufacturer for the Mil Mi-8 and the export version of Mi-17th She is the most commonly built-turbine helicopter in the world. The starting power is 1,500 hp.

The company Klimov in St. Petersburg, Russia, after his former chief designer Vladimir Klimov, who died in 1960 named. His deputy and successor, Sergei Petrovich Isotow, designed the engine and the associated reduction gear. The production took place in the Perm Engine Company, it manufactured more than 23,000 pieces. Successor was the Klimov TV3-117.

Versions:

TV2-117A, (1964), the original version

TV2-117AG, (1985) with improved bearing seal

TV2-117F, for Mi-8FT (with increased emergency power)

TV2-117TG, a testbed for the Mi-8TG, which can be operated with different fuels and under extreme climatic conditions

Technical data:

Start Power: 1500 hp

Specific power consumption at start: 374 g / kWh

Continuous Power: 1000 hp

Specific consumption at continuous power: 421 g / kWh

Length: 2843 mm

Width: 550 mm

Height: 748 mm

Weight: 334 kg

up

CONTINENTAL AVI-1790-8 (KIEPENKERL I + II)

I Kiepenkerl

Kiepenkerl II

Continental AVI 1790-8

These engines of type AVI-1790-8 were installed in the recovery tank including MX 48th The motor is powered by two large fans that sit on him in a special enclosure, are cooled. They are driven by the crankshaft via the front-seated control gearbox using Axialgetriebes. For about 200 hp engine power are needed. The camshaft is driven by vertical shafts.

Each cylinder has two spark plugs of the engine and therefore two magnetic-ignition of the make-Bendix Scintilla or Bosch-American. In addition, two injectors, a fuel pump as a vane pump and an electric fuel pump from Continental Energy.

Technical data:

Displacement: about 29.4 liters

Cylinder: V 12, 90 °

Bore: 146.1 mm

Stroke: 146.1 mm

Compression ratio: 6,5: 1

Power: 820 hp at 2,800 rev /

Torque: 2260 Nm or 226 kpm at 2,250 U /

Idle speed: 650 rpm /

Full speed in the tank: 2800-2830 rpm /

Curb weight: 1384 kg

Of electronic data:

Battery system: 24 V, 200 AH

Generator: 27.5 V, 300 A

Speed of the starter: 42 U / min

Torque of the starter: 1240 Nm or 124 kpm

-----------------------------------------------

Sorry for the massive derail.