| Advertisement |

|

|

|

|

|

|

|

If this is your first visit, be sure to check out the FAQ by clicking the link above.

You may have to register before you can post: click the register link above to proceed.

To start viewing messages, select the forum that you want to visit from the selection below.

|

01-03-2013, 10:06 PM

01-03-2013, 10:06 PM

|

#101

|

Name: JoshH

Title: Too Much Time

Status: Not Here

Join Date: Apr 2007

Location: Tyler, Texas

Member`s Gallery

Posts: 648

|

Yep, I forgot to divide the stroke by 2. Give me a minute, and I'll rerun the calculations.

124 degree angle sprays the edge of the bowl at 42.7 degrees of timing and the cylinder wall at 50.2 degrees of timing.

143 degree angle sprays the edge of the bowl at 32.4 degrees of timing and the cylinder wall at 40.2 degrees of timing.

Sorry for the miscalculations earlier.

Last edited by JoshH; 01-03-2013 at 10:19 PM.

|

|

|

|

01-03-2013, 11:23 PM

01-03-2013, 11:23 PM

|

#102

|

Name: cquestad

Title: Too Much Time

Status: Not Here

Join Date: Oct 2007

Member`s Gallery

Posts: 1,696

|

How do you calculate the time it takes up for the fuel to actually reach its destination from the time the soleniod is signaled to fire? Are those numbers assuming zero?

Smokem...share someething other than more questions. You have skipped all of my questions.

tampax...piss off. Lol

__________________

04 Dodge MPI/Ultimate/F1/Smarty/Thuren 917hp and on a serious build

07.5 Dodge 3500

12 Dodge 3500

Quote:

Originally Posted by nwpadmax

I'm pretty sure your awesomeness gets in the way of seeing anyone else's results.

|

|

|

|

|

01-03-2013, 11:25 PM

01-03-2013, 11:25 PM

|

#103

|

Name: Tate

Title: What?

Status: Not Here

Join Date: Nov 2007

Location: Airdrie, Alberta

Member`s Gallery

Posts: 3,419

|

Quote:

Originally Posted by JoshH

Yep, I forgot to divide the stroke by 2. Give me a minute, and I'll rerun the calculations.

124 degree angle sprays the edge of the bowl at 42.7 degrees of timing and the cylinder wall at 50.2 degrees of timing.

143 degree angle sprays the edge of the bowl at 32.4 degrees of timing and the cylinder wall at 40.2 degrees of timing.

Sorry for the miscalculations earlier.

|

What are you using for a measurement for the nozzle below the piston crown at TDC? 0.050?

I got 55.9 degrees to the edge of the bowl, and 58.5 to the cylinder wall. I didn't put in a value for the nozzle depth, though.

__________________

'98 3500 2wd, 24v, 5 spd, p-pumped

'98 2500 4wd, 12v, 6 spd, VP'd

'02 VW Jetta, 5 spd.

My p-pump conversion pics

|

|

|

|

01-03-2013, 11:34 PM

01-03-2013, 11:34 PM

|

#104

|

Name: nwpadmax

Title: Turbo Geek

Status: Not Here

Join Date: Nov 2006

Location: Out in the shop

Member`s Gallery

Posts: 3,128

|

Quote:

Originally Posted by cquestad

How do you calculate the time it takes up for the fuel to actually reach its destination from the time the soleniod is signaled to fire? Are those numbers assuming zero?

Smokem...share someething other than more questions. You have skipped all of my questions.

tampax...piss off. Lol

|

Funny, tech questions from a guy who "never pays attention to details" and is always so busy hauling something or stroking himself (or both at the same time).

__________________

"What I said does equate too what can happen....Alote."

|

|

|

|

01-03-2013, 11:36 PM

01-03-2013, 11:36 PM

|

#105

|

Name: chris lang

Title: Too Much Time

Status: Not Here

Join Date: Jun 2010

Member`s Gallery

Posts: 843

|

Quote:

Originally Posted by Smokem

Look at is this way, what if we were limited to only using the marine nozzles in the mechanical engines, would we see the same level of results? The simple answer is no, there are many nozzle choices in both mechanical and CR systems, the work needs to be put into finding better options as has been done on the mechanical side for quite some time. I have a few nozzles I will be testing early this year, they are not from a Cummins application. |

Duramax?

|

|

|

|

01-03-2013, 11:45 PM

01-03-2013, 11:45 PM

|

#106

|

Name: cquestad

Title: Too Much Time

Status: Not Here

Join Date: Oct 2007

Member`s Gallery

Posts: 1,696

|

Quote:

Originally Posted by nwpadmax

Funny, tech questions from a guy who "never pays attention to details" and is always so busy hauling something or stroking himself (or both at the same time).

|

Ok..your right. I will just sign off and focus on stroking myself. That will still provide greater results than I have ever seen from your pompous azz.

__________________

04 Dodge MPI/Ultimate/F1/Smarty/Thuren 917hp and on a serious build

07.5 Dodge 3500

12 Dodge 3500

Quote:

Originally Posted by nwpadmax

I'm pretty sure your awesomeness gets in the way of seeing anyone else's results.

|

|

|

|

|

01-03-2013, 11:50 PM

01-03-2013, 11:50 PM

|

#107

|

Name: nwpadmax

Title: Turbo Geek

Status: Not Here

Join Date: Nov 2006

Location: Out in the shop

Member`s Gallery

Posts: 3,128

|

Quote:

Originally Posted by cquestad

Ok..your right. I will just sign off and focus on stroking myself. That will still provide greater results than I have ever seen from your pompous azz.

|

I'm pretty sure your awesomeness gets in the way of seeing anyone else's results.

__________________

"What I said does equate too what can happen....Alote."

|

|

|

|

01-04-2013, 12:07 AM

01-04-2013, 12:07 AM

|

#108

|

Name: cquestad

Title: Too Much Time

Status: Not Here

Join Date: Oct 2007

Member`s Gallery

Posts: 1,696

|

Thanks for the good sig material. Not sure what else you accomplished.

Good luck all with this one...I am out.

__________________

04 Dodge MPI/Ultimate/F1/Smarty/Thuren 917hp and on a serious build

07.5 Dodge 3500

12 Dodge 3500

Quote:

Originally Posted by nwpadmax

I'm pretty sure your awesomeness gets in the way of seeing anyone else's results.

|

Last edited by cquestad; 01-04-2013 at 12:09 AM.

|

|

|

|

01-04-2013, 06:32 AM

01-04-2013, 06:32 AM

|

#109

|

Name: triton

Title: Scarlet Fever

Status: Not Here

Join Date: May 2007

Member`s Gallery

Posts: 5,497

|

with those calculations, I'd say there's never going to be a problem spraying outside the bowl. Max timing... for my truck anyway is 28* using EFI. The only values I've seen close to being as high as calculated was reading the timing tables from a Diablo programmer which were in the 50*'s. Smarty could be up there too ??

|

|

|

|

01-04-2013, 06:54 AM

01-04-2013, 06:54 AM

|

#110

|

Name: zstroken

Title: For $$$ your name here

Status: Not Here

Join Date: Sep 2006

Location: Western Michigan(by the lake)

Member`s Gallery

Posts: 23,151

|

Quote:

Originally Posted by JoshH

Yep, I forgot to divide the stroke by 2. Give me a minute, and I'll rerun the calculations.

124 degree angle sprays the edge of the bowl at 42.7 degrees of timing and the cylinder wall at 50.2 degrees of timing.

143 degree angle sprays the edge of the bowl at 32.4 degrees of timing and the cylinder wall at 40.2 degrees of timing.

Sorry for the miscalculations earlier.

|

Quote:

Originally Posted by cquestad

How do you calculate the time it takes up for the fuel to actually reach its destination from the time the soleniod is signaled to fire? Are those numbers assuming zero?

Smokem...share someething other than more questions. You have skipped all of my questions.

tampax...piss off. Lol

|

Maybe it travels at the speed of light so it is negligible,

__________________

2008 4x4 Megacab, 68RFE

97 Dodge gone....

24V P-Pump Mafia member #1(retired)

Thanks to Mumau Diesel, Goerend Transmission, Northeast Diesel Service!

|

|

|

|

01-04-2013, 08:51 AM

01-04-2013, 08:51 AM

|

#111

|

Name: DIESEL_POWER

Title: NGM Diesel

Status: Not Here

Join Date: Jul 2006

Member`s Gallery

Posts: 5,178

|

I suspect that Too much PSI will "float" the needle or pintle thats in the nozzel and could cause much different timing and duration "in cylinder" conditions.

This could cause post event leakage and "Accual" event over flow...Just a thought

__________________

Proverbs 3:5-6 (KJV)

5 Trust in the Lord with all thine heart; and lean not unto thine own understanding. 6 In all thy ways acknowledge him, and he shall direct thy paths.

|

|

|

|

01-04-2013, 10:03 AM

01-04-2013, 10:03 AM

|

#112

|

Name: ENafziger

Title: Too Much Time

Status: Not Here

Join Date: Oct 2008

Location: Knoxville, TN

Member`s Gallery

Posts: 843

|

Don, Weston, etc...do people who modify nozzles (honed, EDM, whatever) keep a conical form shape to the holes? If so, do they strive to keep K and Ks factors similar to what Bosch has incorporated, or is that something that is experimented with as well?

There's some very interesting material that was presented recently at work that shows effects of inter-nozzle and near-nozzle cavitation at high pressure. I'll check if it's allowable to post in the public domain. They used a 1,000,000 fps camera to look at flow through an acrylic window in a portion of a CR injector nozzle. Pretty amazing stuff.

--Eric

__________________

2006 Dodge 3500 SRW, 62/476 twins, Flux 2.5s, G56, Carli 2.65s, etc. Jer. 33:3

2003 Ford Excursion, '97 Cummins P-Pump, HX35/475 twins, studded and o-ringed, ZF6/271, forged Rickson 19.5s.

1991.5 W250, NV4500, Rickson 19.5s, HE351, long travel suspension build

Last edited by ENafziger; 01-04-2013 at 10:09 AM.

|

|

|

|

01-04-2013, 10:11 AM

01-04-2013, 10:11 AM

|

#113

|

Name: Smokem

Title: Turbler

Status: Not Here

Join Date: May 2006

Location: Iowa

Member`s Gallery

Posts: 5,565

|

Quote:

Originally Posted by triton

Don or Weston, have you done any testing with them and what did you find if you did?

|

Sorry, I have no experience with them.

Quote:

Originally Posted by chris lang

Duramax?

|

No.

|

|

|

|

01-04-2013, 11:05 AM

01-04-2013, 11:05 AM

|

#114

|

Name: Diesel Tech

Title: #1 Crusty Old Fart

Status: Not Here

Join Date: Apr 2006

Member`s Gallery

Posts: 1,231

|

The K and Ks factors cannot really be controlled when using an extrude hone. The Extrude hone removes material from a hole and you have little to no control over it. It is best to do what it was designed for and that is to remove sharp edges. As the material runs over a restriction it begins cutting that material away. Based on how hard the material is and what media your running through the machine is how fast it will cut. Another big thing is that the holes are very small and the grit in the media can and does cause those holes to get plugged up. This is one of the biggest problems when people do not pay attention when running the equipment. Most of the tooling for running the extrude hone machine on injector nozzles does NOT allow you to see what is happening so your cannot see a hole got plugged until AFTER the machine cycle is completed. At that point it's to late most of the time.

nwpadmax has a great picture of a plugged injector nozzle hole from a Extrude Hone nozzle that stayed plugged even after they were install and run in an engine. When it didn't run right the injectors got removed and the problem found. With that said I still believe the Extrude hone process is good when used correctly.

There is just so much to this that a quick swap of nozzles alone is not going to show that is why I say you need a lot more information to really know and understand what is going on.

__________________

Tuners of quick and fast Duramax pickups.

"I would rather lose going fast enough to win than win going slow enough to lose."

|

|

|

|

01-04-2013, 12:02 PM

01-04-2013, 12:02 PM

|

#115

|

Name: mikmaze

Title: Too Much Time

Status: Not Here

Join Date: Apr 2009

Location: Fairfield NJ

Member`s Gallery

Posts: 4,292

|

I missed the part where duration plays into this? if duration is x long, don't you see half of that before the injectors time of fire, and half after?

__________________

04.5 Qcab shorty EVIL TWIN CP3's 100 % over nozzles, ats 3 piece, HTT 64 71 13 ss over S480, arp's , GOEREND , Hamilton 181 210 & valve springs, UDC beta

2006 Liberty CRD w/ GDE eco

'91 JD 1070 dzl

|

|

|

|

01-04-2013, 12:34 PM

01-04-2013, 12:34 PM

|

#116

|

Name: cquestad

Title: Too Much Time

Status: Not Here

Join Date: Oct 2007

Member`s Gallery

Posts: 1,696

|

Quote:

Originally Posted by mikmaze

I missed the part where duration plays into this? if duration is x long, don't you see half of that before the injectors time of fire, and half after?

|

Don't think so...duration is the time it stays open after the command to fire.

What rod length were you using? I got more like 38 degrees or so on a 143 degree on a stock bore before it hits the walls?

__________________

04 Dodge MPI/Ultimate/F1/Smarty/Thuren 917hp and on a serious build

07.5 Dodge 3500

12 Dodge 3500

Quote:

Originally Posted by nwpadmax

I'm pretty sure your awesomeness gets in the way of seeing anyone else's results.

|

|

|

|

|

01-04-2013, 12:56 PM

01-04-2013, 12:56 PM

|

#117

|

Name: JoshH

Title: Too Much Time

Status: Not Here

Join Date: Apr 2007

Location: Tyler, Texas

Member`s Gallery

Posts: 648

|

Quote:

Originally Posted by Tate

What are you using for a measurement for the nozzle below the piston crown at TDC? 0.050?

I got 55.9 degrees to the edge of the bowl, and 58.5 to the cylinder wall. I didn't put in a value for the nozzle depth, though.

|

No, like I stated in my first post, I don't have that information, so I just assumed the tip of the injector to be even with the top of the piston (I know it isn't, but I didn't think it would change my numbers by that much). If I used .050 with the 124 degree nozzle, it raises the timing at which the spray will hit the edge of the bowl to 44.1 degrees instead of 42.7 degrees. What are you using for stroke, rod length, spray angle, and bowl diameter to get your numbers? What formula are you using to calculate the angle?

|

|

|

|

01-04-2013, 01:16 PM

01-04-2013, 01:16 PM

|

#118

|

Name: Smokem

Title: Turbler

Status: Not Here

Join Date: May 2006

Location: Iowa

Member`s Gallery

Posts: 5,565

|

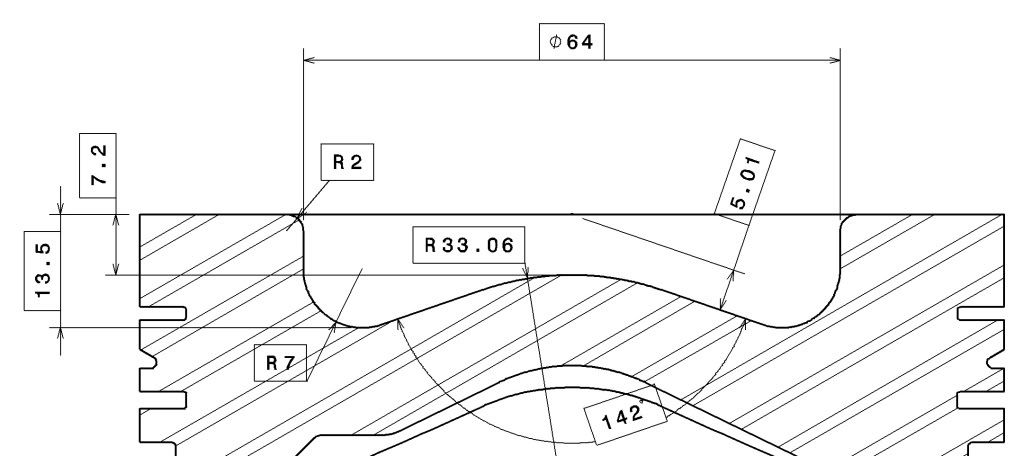

I'll add the following just to show that a wide cone angle can be used successully in a smaller bowl than many think.

Duramax piston using a 158° cone angle

|

|

|

|

01-04-2013, 01:29 PM

01-04-2013, 01:29 PM

|

#119

|

Name: Joesixpack

Title: Pull'n it.

Status: Not Here

Join Date: Apr 2008

Member`s Gallery

Posts: 4,118

|

Quote:

Originally Posted by cquestad

Don't think so...duration is the time it stays open after the command to fire.

What rod length were you using? I got more like 38 degrees or so on a 143 degree on a stock bore before it hits the walls?

|

Duration includes electrical/hydraulic latency.

__________________

Basically stock if I would have built it at the factory.....

|

|

|

|

01-04-2013, 01:35 PM

01-04-2013, 01:35 PM

|

#120

|

Name: phale

Title: Too Much Time

Status: Not Here

Join Date: Dec 2006

Member`s Gallery

Posts: 935

|

Quote:

Originally Posted by mikmaze

I missed the part where duration plays into this? if duration is x long, don't you see half of that before the injectors time of fire, and half after?

|

Depends on your timing, it has been said that a 50/50 split is optimal for power, mpg, and durability but in the case of a tune running big duration you would have to run 35+ degrees to keep a 50/50 split.

__________________

ANARCHY DIESEL TUNING

EFI Live Beta Tester Cummins/Duramax tuning

423-506-7427

|

|

|

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is Off

|

|

|

All times are GMT -5. The time now is 07:17 PM.

|