Since I want to paint the engine before I'm all done, I need to get as much of the grease and chipped paint off as possible first. So off to the car wash we go!

Back from the car wash I actually took the time to assemble some sort of crate to sit the engine on.

The first thing I did to the engine was to tackle the rear freeze plug. I don't really intend to run a lot of rpm with this truck, the fear of this freeze plug leaking on me while in the truck worries me. So I bought a billet rear freeze plug from eatsoot.com that shouldn't leak at all. Plus this lets me install a coolant bypass later if I decide that is needed.

Simply tap out the original freeze plug....

Then a light film of grease on the O-ring and bolt in the billet freeze plug. I'm really impressed with the quality and price of this piece.

Then I replaced the rear main seal.

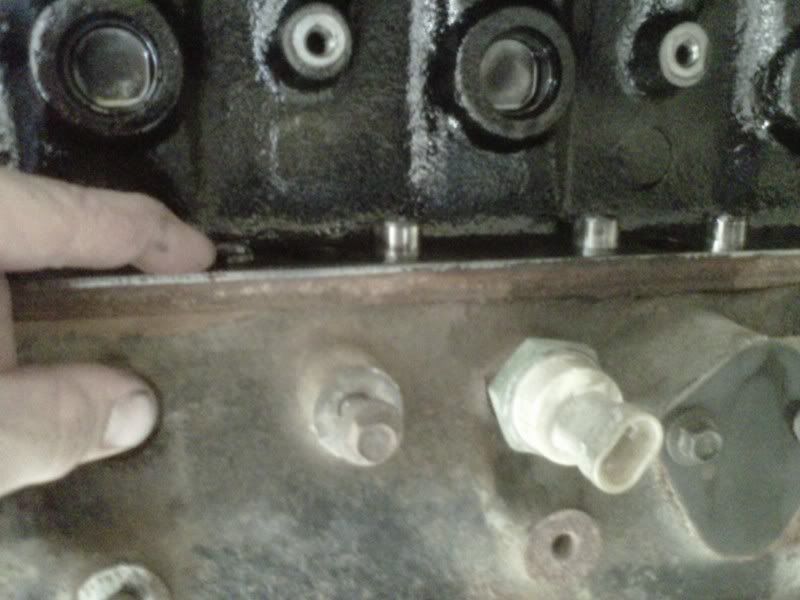

Next I decided to get the 12valve gear housing ready by removing the TDC pin from the housing.

Then I bolted the cam sensor relocation block in place of the TDC pin.

You can see how much material that you have to remove in order to place the cam sensor properly. I simply followed the instructions which tell you to mark the area that needs to be removed and grind it away. Again, this piece is from eatsoot.com and am impressed with both the quality and price of this piece.

Now I'm ready to start tearing the engine down! So back up on the flywheel housing it goes. I rotated the camera to make the engine look like it was sitting normally and wasn't hard to look at.

Oh no, now my warranty is voided! I couldn't resist taking this picture.

First off come the injection lines.

Then the fuel filter.

Then the

VP44 injection pump.

Then the ECM and the wire harness.

Next the tappet cover comes off.

Then the valve cover, along with the push tubes and rockers.

Here's a picture of the entire engine at this point.

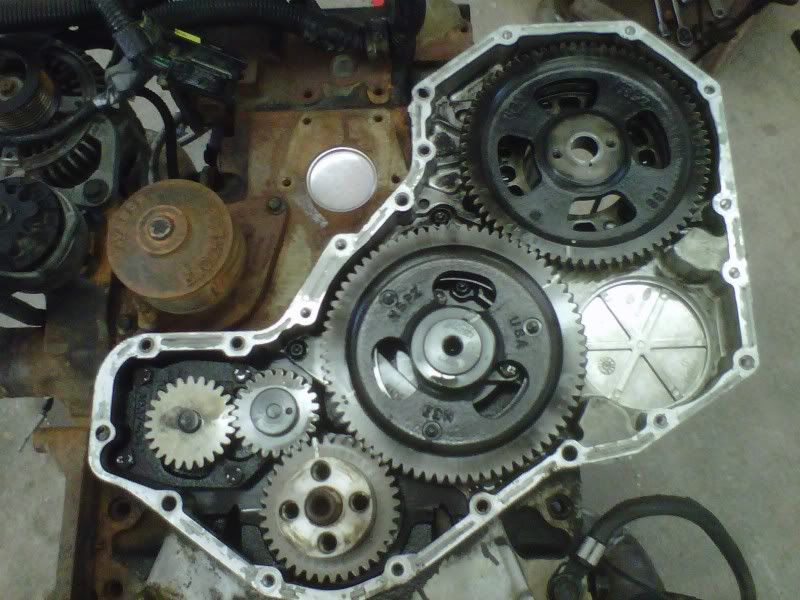

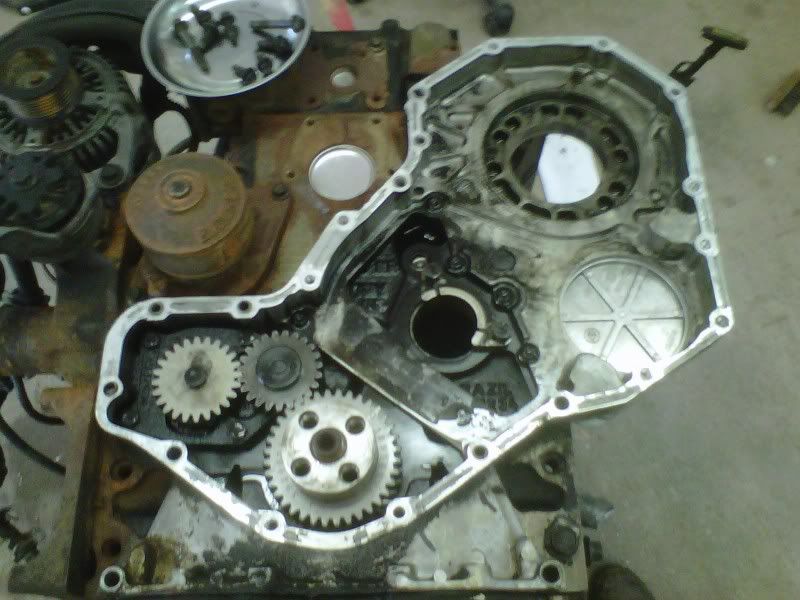

Focusing on the gear train.

No need for the

VP44 pump drive gear anymore. Now I'm ready to pull the cam out. I've never done any of this (but have wanted to ever since I can remember) so I'm really anxious at this point.

First I have to unbolt the cam retainer.

Cam coming out.

Cam is out!

"Look ma, no dowel rods!" Here's probably the biggest advantage to sitting the engine on the flywheel housing to do this job. I don't have to worry about the tappets falling because gravity isn't pulling them down.

Next I take off the 24valve gear housing. I ended up taking the oil pump off too so that I could scrape the old gasket off better.