| Advertisement |

|

|

|

|

|

|

|

If this is your first visit, be sure to check out the FAQ by clicking the link above.

You may have to register before you can post: click the register link above to proceed.

To start viewing messages, select the forum that you want to visit from the selection below.

|

| Dodge Competition and Performance General Dodge Competition and Performance Discussion |

11-20-2009, 06:47 AM

11-20-2009, 06:47 AM

|

#21

|

Name: SWALLDOG

Title: Too Much Time

Status: Not Here

Join Date: Jun 2008

Location: Woods Cross, Utah

Member`s Gallery

Posts: 454

|

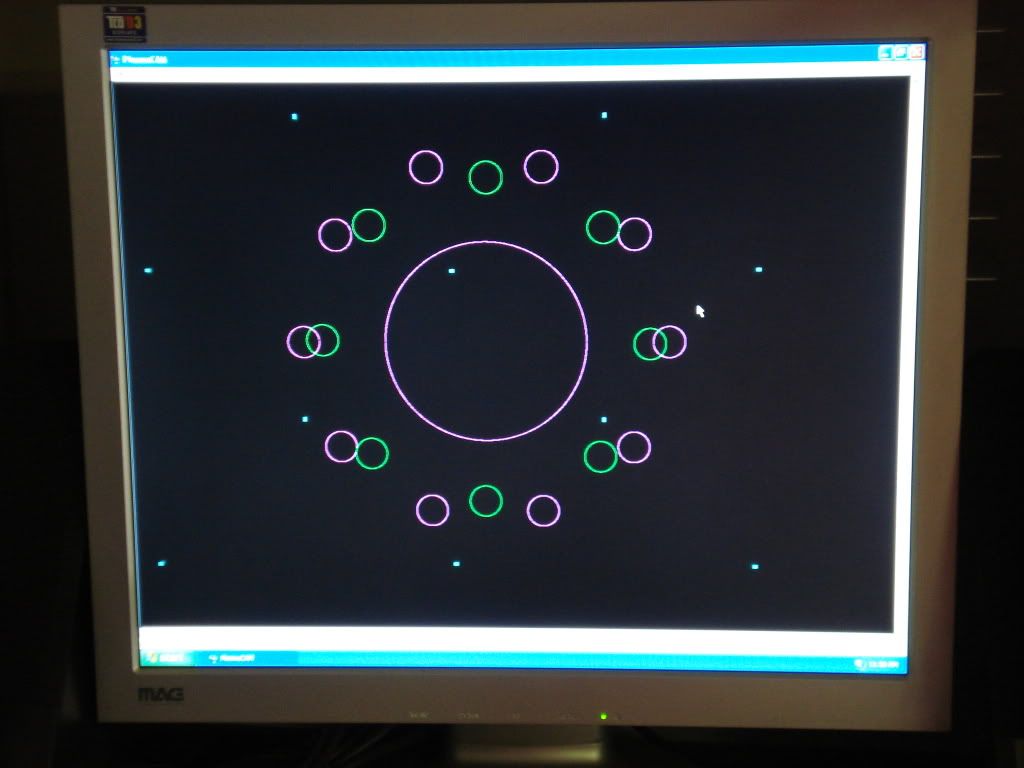

my buddie and i played around with how to re-machine the holes. no matter how we rotated it at least 4 holes intersected. 2 on each side. so i welded in 4 of the 10 holes. 2 on each side. figured that would be the best.

|

|

|

|

11-20-2009, 06:48 AM

11-20-2009, 06:48 AM

|

#22

|

Name: SWALLDOG

Title: Too Much Time

Status: Not Here

Join Date: Jun 2008

Location: Woods Cross, Utah

Member`s Gallery

Posts: 454

|

|

|

|

|

11-20-2009, 06:49 AM

11-20-2009, 06:49 AM

|

#23

|

Name: SWALLDOG

Title: Too Much Time

Status: Not Here

Join Date: Jun 2008

Location: Woods Cross, Utah

Member`s Gallery

Posts: 454

|

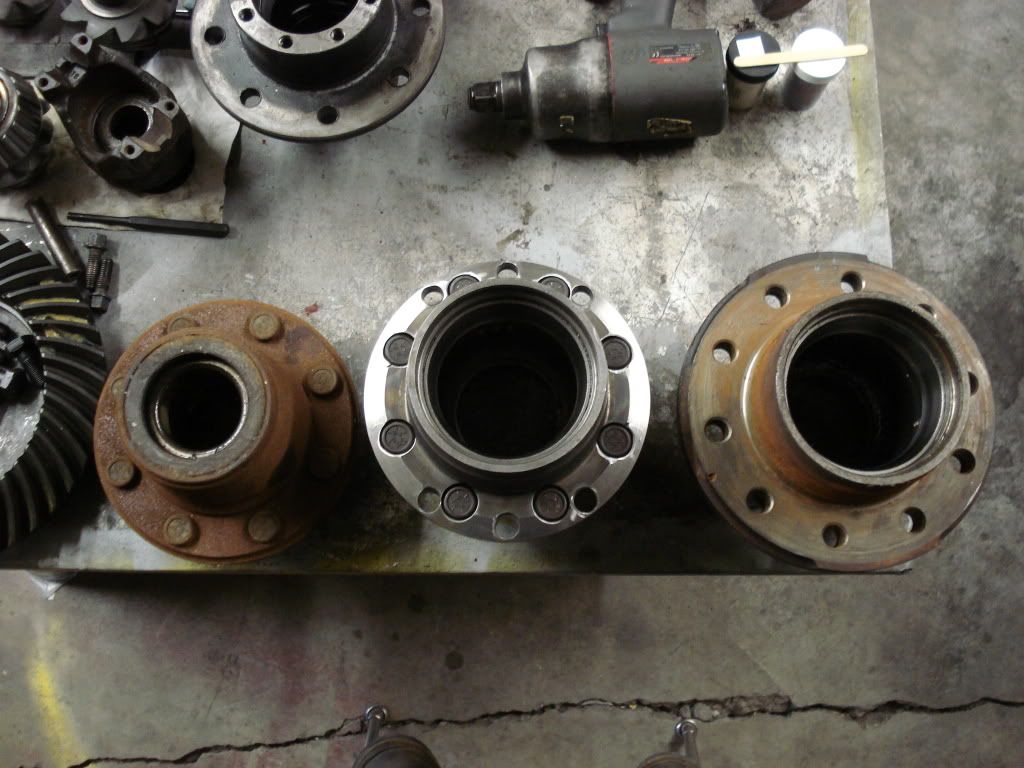

here is the hub all machined. had to turn it down small enough to get the stock dodge rotors to fit over it.

left to right. stock dodge dana 80 hub, machined 10 lug hub, stock 10 lug hub. look at the diffrence in the bearing size. :shock:

the two 10 lug dana 80 hubs before and after machining.

|

|

|

|

11-20-2009, 06:51 AM

11-20-2009, 06:51 AM

|

#24

|

Name: SWALLDOG

Title: Too Much Time

Status: Not Here

Join Date: Jun 2008

Location: Woods Cross, Utah

Member`s Gallery

Posts: 454

|

|

|

|

|

11-20-2009, 06:52 AM

11-20-2009, 06:52 AM

|

#25

|

Name: SWALLDOG

Title: Too Much Time

Status: Not Here

Join Date: Jun 2008

Location: Woods Cross, Utah

Member`s Gallery

Posts: 454

|

i was going to machine some plate to make a spacer that that would just clamp between the hub and the brake bracket so i could weld it in place. the center hole was machined pretty close to to the size on the axle tubing. figured it would center it really well. then my buddie said i should just machine a spacer out of tube that fits over the lip on the flange and in the step in the hub. then it would be perfectly centered. :headbang: got some 5" OD 1/2" wall DOM tubing and cut a chunk off.

spacer all machined.

test fit

installed and clamped with backing plate tacked in place

all welded up. one pass on the out side and three passses on the inside. the inside of the plate had a big bevel machined in it to get some good penitration. all welds were done in sections and alowed to cool before the next pass. dont want any thing warping. :thumbsup:

|

|

|

|

11-20-2009, 06:53 AM

11-20-2009, 06:53 AM

|

#26

|

Name: SWALLDOG

Title: Too Much Time

Status: Not Here

Join Date: Jun 2008

Location: Woods Cross, Utah

Member`s Gallery

Posts: 454

|

this is just a pic of me makin some set up carrier bearings for the dana 80. when my friend and i were going to set up the ring and pinion, well let me back up. so this 10 lug dana 80 had new carrier, 4.10 gears and bearings, but when i pulled it all apart i knew that it was not set up right. it was pretty bad. so i bought a shim kit so we could re-set up the gears. well when we started to pull the carrier bearings off things got worse. the bearings looked new but the races were defiantly old. same with the front pinion bearing and the pinion dam was all bent up. so i ordered a full install kit. new bearings and all. :thumbsup: so with the old carrier bearings, that were still new, i polished out the inside so they would just barley slide on the carrier. that way i dont have to press them on and off when changing shims. then once its set up press the good bearings on. :thumbsup:

|

|

|

|

11-20-2009, 06:56 AM

11-20-2009, 06:56 AM

|

#27

|

Name: SWALLDOG

Title: Too Much Time

Status: Not Here

Join Date: Jun 2008

Location: Woods Cross, Utah

Member`s Gallery

Posts: 454

|

my buddie cut me out some spring perches on his plas table. turned out pretty slick.

all welded up on the axle.

|

|

|

|

11-20-2009, 07:01 AM

11-20-2009, 07:01 AM

|

#28

|

Name: SWALLDOG

Title: Too Much Time

Status: Not Here

Join Date: Jun 2008

Location: Woods Cross, Utah

Member`s Gallery

Posts: 454

|

hubs painted ready to install.  arty018:

|

|

|

|

11-20-2009, 07:02 AM

11-20-2009, 07:02 AM

|

#29

|

Name: SWALLDOG

Title: Too Much Time

Status: Not Here

Join Date: Jun 2008

Location: Woods Cross, Utah

Member`s Gallery

Posts: 454

|

the last thing (for now) that i'm working on, to get it back on the road, is the wheel speed sensor. i drilled a hole in the housing before i got all the gears installed. today (guess it would be yesterday now) i got the block all machined that holds the sensor in place. forgot to take some pics.  but today after i get home from work and get some sleep, i should have it welded on. then i can throw the axle in and take it for a burn! :headbang:

|

|

|

|

11-20-2009, 06:27 PM

11-20-2009, 06:27 PM

|

#30

|

Name: kalder

Title: Kevin Alder

Status: Not Here

Join Date: Oct 2006

Location: Kittitas Valley, WA

Member`s Gallery

Posts: 1,286

|

Wow! Nice work!

__________________

Kevin

03 3500

|

|

|

|

11-20-2009, 07:04 PM

11-20-2009, 07:04 PM

|

#31

|

Name: jackblack99

Title: Too Much Time

Status: Not Here

Join Date: Sep 2008

Member`s Gallery

Posts: 1,813

|

thats sweet man. good job!

__________________

03 RCLB Lb7 6spd.

|

|

|

|

11-20-2009, 07:18 PM

11-20-2009, 07:18 PM

|

#32

|

Name: milldog

Title: Yup...

Status: Not Here

Join Date: May 2009

Member`s Gallery

Posts: 108

|

I need to buy some more tools!!! First off a lathe...

__________________

04.5 A little extra fuel and air

|

|

|

|

11-20-2009, 08:02 PM

11-20-2009, 08:02 PM

|

#33

|

Name: jordanjames81

Title: Too Much Time

Status: Not Here

Join Date: Jan 2009

Location: marion, ky

Member`s Gallery

Posts: 3,411

|

nice fab work

__________________

Hidden Valley Diesel Performance

BD Diesel Performance

Industrail Injection

Amsoil oil Dealer

AirDog Fuel Systems

Farmer's Machine

AutoMeter Gauges

AFE Power

Check us out on FaceBook

Incompatible Browser | Facebook

|

|

|

|

11-20-2009, 10:44 PM

11-20-2009, 10:44 PM

|

#34

|

Name: SWALLDOG

Title: Too Much Time

Status: Not Here

Join Date: Jun 2008

Location: Woods Cross, Utah

Member`s Gallery

Posts: 454

|

Quote:

Originally Posted by kalder

Wow! Nice work!

|

Quote:

Originally Posted by jackblack99

thats sweet man. good job!

|

Quote:

Originally Posted by jordanjames81

nice fab work

|

THANKS! its finally comming together.

|

|

|

|

11-20-2009, 11:49 PM

11-20-2009, 11:49 PM

|

#35

|

Name: SWALLDOG

Title: Too Much Time

Status: Not Here

Join Date: Jun 2008

Location: Woods Cross, Utah

Member`s Gallery

Posts: 454

|

|

|

|

|

11-21-2009, 05:16 AM

11-21-2009, 05:16 AM

|

#36

|

Name: Chevycummins

Title: Bad case of Tinkeritis!

Status: Not Here

Join Date: Jul 2008

Member`s Gallery

Posts: 3,488

|

nice work. got some pretty good fab skills. wish i had time to do something like that with my cummins conversion.

could you not use like a pop can or something and cut you out a couple shims to space that back to your 0.020???

__________________

2020 Ram 2500 4x4 Big Horn

|

|

|

|

11-22-2009, 06:33 AM

11-22-2009, 06:33 AM

|

#37

|

Name: SWALLDOG

Title: Too Much Time

Status: Not Here

Join Date: Jun 2008

Location: Woods Cross, Utah

Member`s Gallery

Posts: 454

|

|

|

|

|

11-22-2009, 06:47 AM

11-22-2009, 06:47 AM

|

#38

|

Name: SWALLDOG

Title: Too Much Time

Status: Not Here

Join Date: Jun 2008

Location: Woods Cross, Utah

Member`s Gallery

Posts: 454

|

Quote:

Originally Posted by Chevycummins

nice work. got some pretty good fab skills. wish i had time to do something like that with my cummins conversion.

could you not use like a pop can or something and cut you out a couple shims to space that back to your 0.020???

|

thanks man! yeah pop can for custom shims is a great idea. i just stuck 2 small pinion shims in there for now. kinda geto but i wanted to get it on the road. worked for today.

|

|

|

|

11-22-2009, 08:15 AM

11-22-2009, 08:15 AM

|

#39

|

Name: JFlagg

Title: Gun for Hire

Status: Not Here

Join Date: Jul 2007

Location: St. Louis, MO

Member`s Gallery

Posts: 5,630

|

Thats some nice machine work and fabbing you did there! I think the 37 spline is a good upgrade for the D80's. That, along with the bigger bearings and 4.10's should make for a great rearend for a tow rig. Now the next question is, when are you doing the 4.10's in the front? Or did you do that at the same time, but didn't mention it since it didn't require any fancy fab work?

__________________

P-pumped 24V... with a few mods

|

|

|

|

11-22-2009, 08:19 AM

11-22-2009, 08:19 AM

|

#40

|

Name: Goinbyyabig

Title: Free Thinker, Innovator

Status: Not Here

Join Date: Apr 2009

Member`s Gallery

Posts: 185

|

X2 on the "I need to buy some more tools", having access to the lathe, bridgeport, welders, etc. is nice but only part of the game. You have some excellent fab and machining skills man, takes brains as well for that stuff to come out right and last, keep us posted!!

|

|

|

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is Off

|

|

|

All times are GMT -5. The time now is 01:46 AM.

|