runsideways2

New member

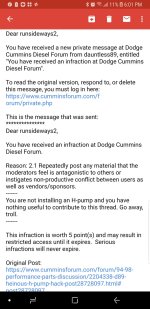

I'm not going to post a link to a page that got me charged with trolling. D89 is a mod over there and he made a assumption that nobody else could get a h pump retrofitted to a 12 valve and deleted my post. Its upsetting that someone would suspend me because I might be tearing Into his profit that he is trying to turn out of what is suppose to be a place for help when we have issues with our trucks as there is not to many shops out there that work on these ol'12 valves. Let alone do something that is good for performance and Mother nature.Got a link? What all is involved to add one? What size barrels ? Hows the timing work