RonA

Active member

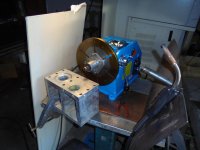

My M&K products unit quit on me for a second time so I bit the bullet and bought another(larger) unit. Place back east called All-fab. Larger unit with muck heavier grounding capability. Got about 10 years out of the M&K unit so if I can get at least that much out of the new one I'll be fine.