You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

building traction bars

- Thread starter crash85

- Start date

rbmedic75

Cummins Fanatic

As to what material all depends on what HP and class your running in. I am going to assume your running in a street type class and 500 HP +/-. Commonly used is 2" schedule 40 pipe, higher dollar would be 2" .250 DOM tubing about $15-17 per foot. A comfortable length seems to be mid point of the rear door area. Short bars will put a lot more force on the frame and could cause problems, so try to stay at least to the back of the cab preferable the mid rear door area that should get ya close to the same angle as the drive shaft.

06 diesel beat me to it lol

06 diesel beat me to it lol

Last edited:

BigBadDodge

New member

2" DOM 1/2" wall and be done with it.

BBD

BBD

jordanjames81

New member

2" DOM 1/2" wall and be done with it.

BBD

This what my new one's are made out of, using 3/4'' eye's welded in them. Mine are on a 03 short bed crew cab cummins. They are 7 ft long.

I used some 2" DOM tubing for my traction bars. I picked it up at the local metal fab shop. I ordered some RH and LH threaded heim joints from Barnes 4WD. They also had some tabs for the rear axle mounts. All I had to do was to drill out the hole to match the heim joint mounting hole. As for traction bars vs. ladder bars, some class rules state that there can only be two mounting points. A ladder bar will not meet that rule.

jlibert

New member

here's the thread on the ones I built...

my ladder bars - Competition Diesel.Com - Bringing The BEST Together

my ladder bars - Competition Diesel.Com - Bringing The BEST Together

why make the links stonger then the heims/rod ends.

just lots of weight with 1/2" thick...............3/8" thick will be just fine...dom is the best.But ive used hrew and poo pipe.usually only run dom for cages pipe for stingers/rock bars and hrew everything else

and id run ballistic fab or evolution machine ends.

ive build a few link set up s with qa1 heims and they wear out very fast

just lots of weight with 1/2" thick...............3/8" thick will be just fine...dom is the best.But ive used hrew and poo pipe.usually only run dom for cages pipe for stingers/rock bars and hrew everything else

and id run ballistic fab or evolution machine ends.

ive build a few link set up s with qa1 heims and they wear out very fast

Last edited:

HIGH TECH RAM

Haters!

Drawn Over Mandrel

Red Sleeper

Active member

I think your answer to that is in the second post..

jlibert, nice write up and great info.

jlibert, nice write up and great info.

rbmedic75

Cummins Fanatic

folow the driveline angle (driveshaft) and should put you very close to the mid section of the rear door...

Pretty sure the .500 wall tubing was suggested by a VERY well respected Professional puller on here because the OP is looking to pull 2.8 class at 800 hp. thats a LOT of axle wrap to tame.

DOM Drawn over Mandrel is TUBING that is "seamless" and measured by OD outside diameter.

regular Pipe is measured by INSIDE diameter and has a visible weld seam in it.

DOM for 2" .500 wal is probably over $20/foot .250 wall is about $15/foot

PIPE is less than $2/foot

I would use the DOM at that HP and Pulling. Buy a full stick Random length of 17'-21'. Most places it will be cheaper if you buy it by the stick (full length)

Pretty sure the .500 wall tubing was suggested by a VERY well respected Professional puller on here because the OP is looking to pull 2.8 class at 800 hp. thats a LOT of axle wrap to tame.

DOM Drawn over Mandrel is TUBING that is "seamless" and measured by OD outside diameter.

regular Pipe is measured by INSIDE diameter and has a visible weld seam in it.

DOM for 2" .500 wal is probably over $20/foot .250 wall is about $15/foot

PIPE is less than $2/foot

I would use the DOM at that HP and Pulling. Buy a full stick Random length of 17'-21'. Most places it will be cheaper if you buy it by the stick (full length)

Last edited by a moderator:

jlibert

New member

I think your answer to that is in the second post..

jlibert, nice write up and great info.

Thanks. They did the job.

-jp

there is way more too it then welding lengths of steel from frame to axle..and they certainly dont need to be ten feet long.

with ladder bar type links it will change your roll axis and actually create less traction. Zero axle wrap but less traction. as you throttle down you would want a weight transfer to the rear and load the tires..creating traction not lifting the rear end.

i was a 4x4 guy before a diesel guy and have learned this the hard way.

a proper link calculator should be used in a race/full performance set-up.

when the time comes for traction bars with my ride it will be 4 linked....your half way their with traction bars just loose the leafs:lolly:

with ladder bar type links it will change your roll axis and actually create less traction. Zero axle wrap but less traction. as you throttle down you would want a weight transfer to the rear and load the tires..creating traction not lifting the rear end.

i was a 4x4 guy before a diesel guy and have learned this the hard way.

a proper link calculator should be used in a race/full performance set-up.

when the time comes for traction bars with my ride it will be 4 linked....your half way their with traction bars just loose the leafs:lolly:

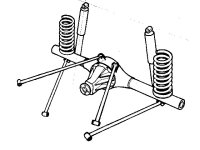

Attachments

Sandaholic

Bangin' through the gears

How? Are you talking about on the front axle? With a ladderbar you would be pushing up on the frame which would in turn drive the rear axle towards the ground......I think?there is way more too it then welding lengths of steel from frame to axle..and they certainly dont need to be ten feet long.

with ladder bar type links it will change your roll axis and actually create less traction. Zero axle wrap but less traction. as you throttle down you would want a weight transfer to the rear and load the tires..creating traction not lifting the rear end.

i was a 4x4 guy before a diesel guy and have learned this the hard way.

a proper link calculator should be used in a race/full performance set-up.

when the time comes for traction bars with my ride it will be 4 linked....your half way their with traction bars just loose the leafs:lolly:

Last edited: