Texashighways

Comp Diesel Sponsor

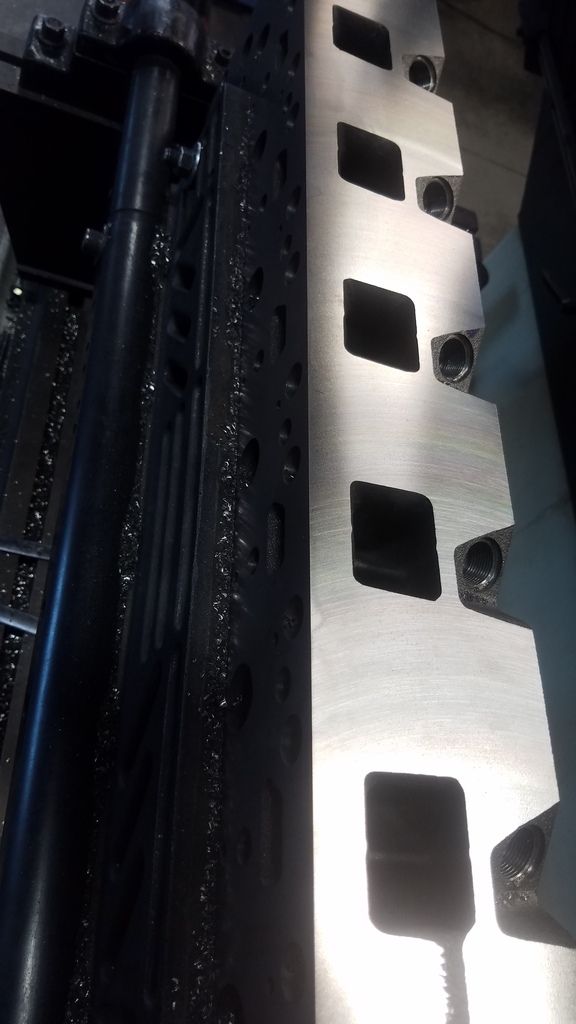

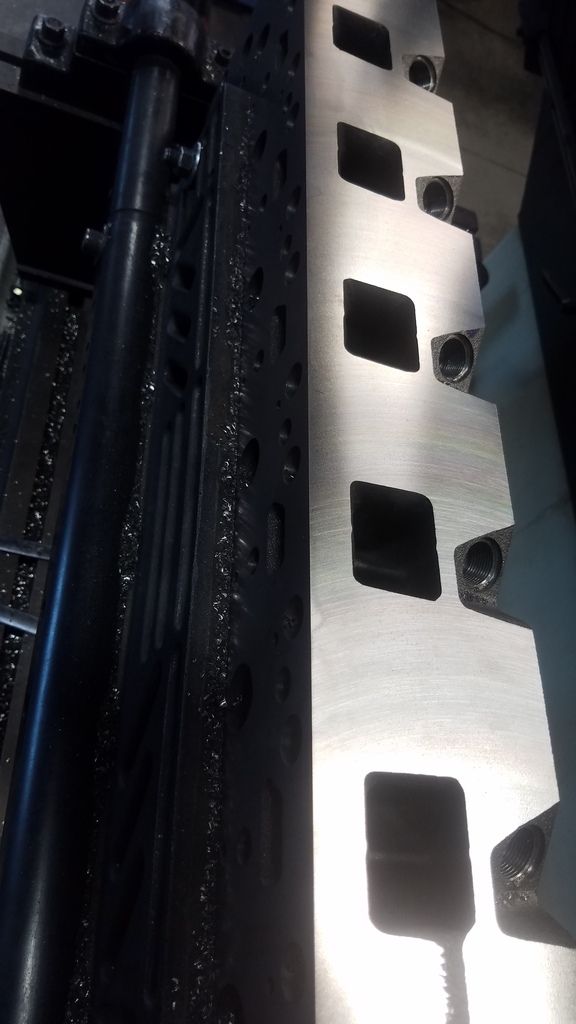

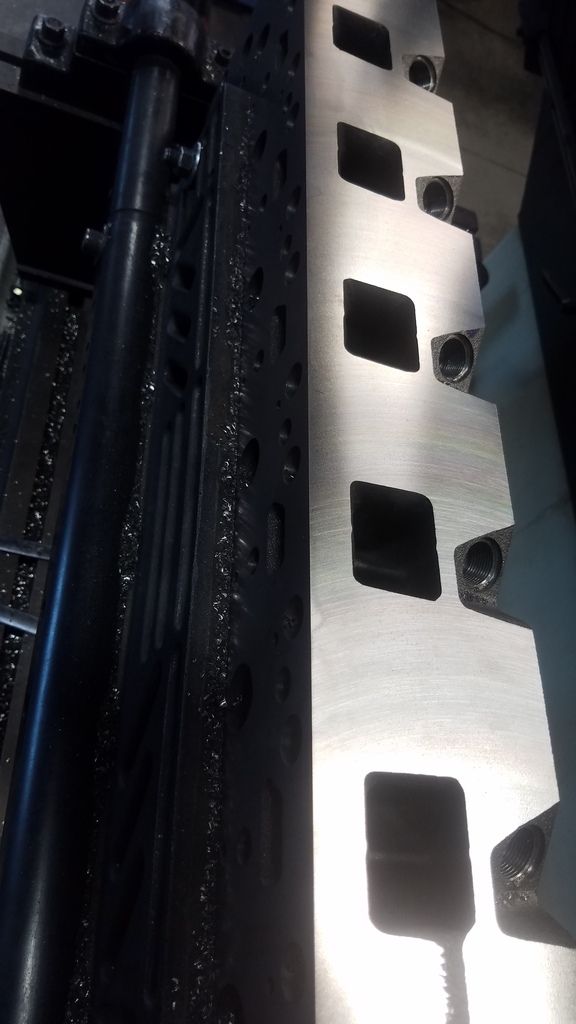

We are testing them this week.

That depends on the sticker on your window.. 250cfm-340cfm or so depending on a ton of factors

Not on the prototypes because we have to buy about 25,000 lbs of material for special non oem material

No VP love!

Sent from my SAMSUNG-SM-G930A using Tapatalk

Be kinda like putting lipstick on a pig though wouldn't it?!It would not take that much work to use it on a vp engine.

Be kinda like putting lipstick on a pig though wouldn't it?!

Sent from my SAMSUNG-SM-G930A using Tapatalk

Be kinda like putting lipstick on a pig though wouldn't it?!

Sent from my SAMSUNG-SM-G930A using Tapatalk

Been a fine pig! Going on 9-1/2 years of faithful service right now! I'm just fairly sure that if I ever have to pull the head, it's probably cracked all around the valves like most of them. But a truck like mine would never spin fast enough to truly take advantage of a head like this I think.How much do you like that pig. :cheer: