Thanks!

It's getting there.

Here's a few things about it and what all is getting done.

Stuff it already had before this build.

SunCoast Trans, TC and Flex

ATS Compounds, intercooler and Waterboy

DDP 160's

PPE Dual CP3's

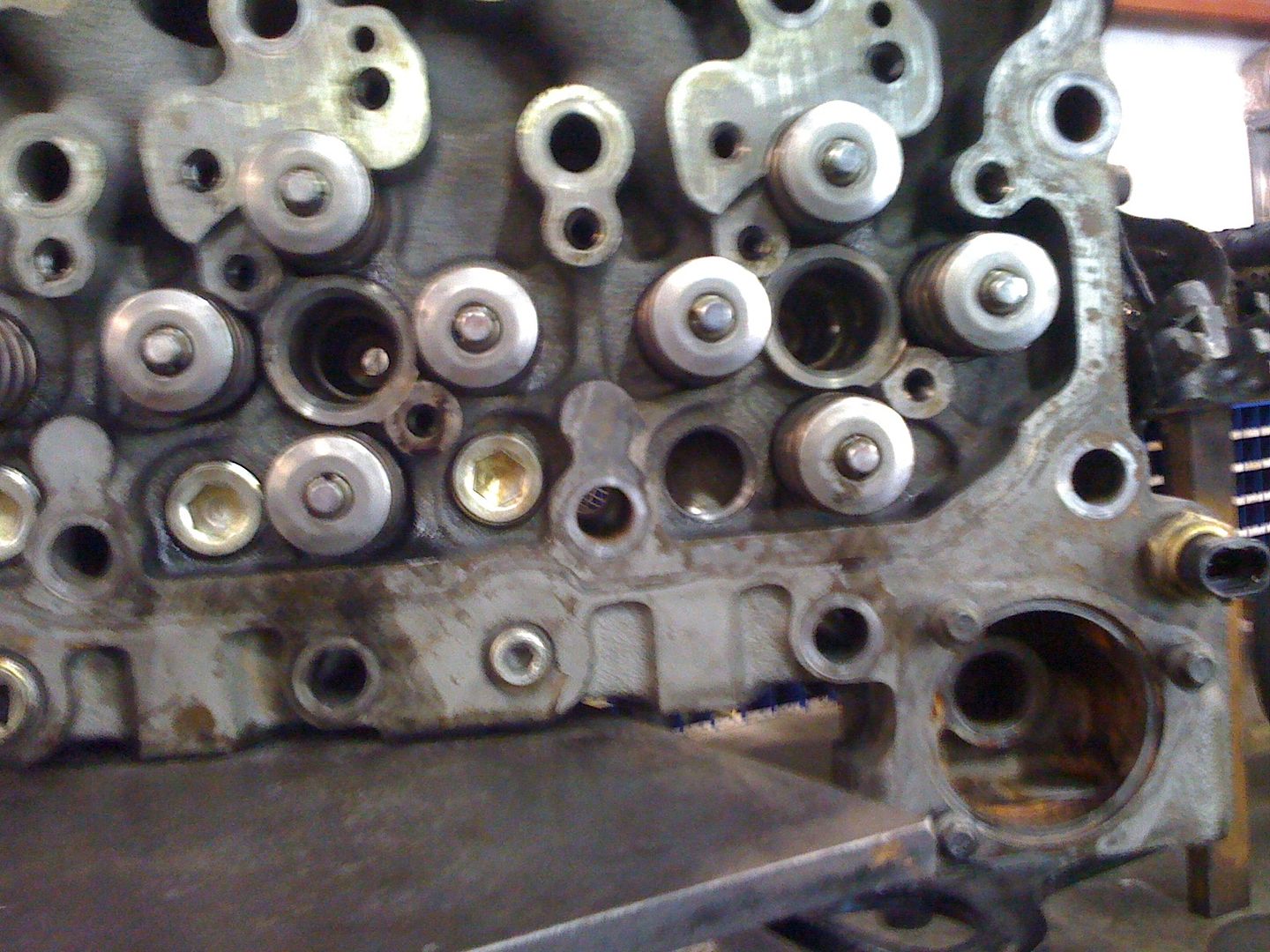

ARP head and rocker studs

Hamilton 110# springs

Billet pushrods

FASS 150

stainless charge piping

CFM+ (being replaced with an S&B on the build)

Smarty TNT/R

Guages (adding drive press, oil press and new trans gauge on the build)

Mag-Hytec pan and covers

a bunch of other small stuff I'm sure I'm forgetting

What it's getting during the build is:

ARP main studs

12V connecting rods

pistons coated (looks like possibly new ones)

head is fire ringed

batteries relocated to the back of the truck, under the bed. Battery cut-out on the rear bumper

electric fans

Hamilton cam

Fluidampr

Nitrous Express NXD4000

TST PowerMax

All the hot side parts of the turbos were blasted and ceramic coated

-10 fuel line from tank to pump and pump to y-fitting. -8 from y to CP3's

fuel tank sump

trans is getting new soft parts

traction bars and driveshaft loops

deleting the OEM filter housing and heat exchanger

Most current numbers the truck put down, before this round of mods was 742 HP / 1492 TQ on fuel.

It's a daily driver, tows the trailer, does all the normal crap that a truck is suppossed to do.