Rustin

Let the Beatings Begin!

- Joined

- Jul 11, 2010

- Messages

- 2,212

Please forgive me if this is long and or vague. If I put everything this thread would be looked past for to much content.

I am not out to try to Start a WAR on opinions. However; it might happen with this thread! I am just looking for guidance, and wondering if I am thinking the right way? I want to inspire out of the box thinking, without trying to reinvent the wheel (I seem to get that allot).

I want to go at it a different way. I have seen allot of injectors over the years including performance injectors, and the fuel pressures have increased, as well as injector timing. When looking back at older trucks (5.9 6bt for an example) We notice the evolution of performance injectors. First it was advance injector timing, then increase fuel pressure, followed by installing Marine injectors (after the initial intake exhaust and others, we will just considers this done throughout this post). Performance Shops discovered the weakness of the originals and started to modify accordingly. These shops and businesses are now the pioneers of diesel performance! Injector orifices were increased in size to allow more fuel (not to mention the pumps were modded to produce more fuel flow) when we start to get into black smoke that is when we are maxed out in timing, fuel pressure.

Question 1. What size are the diesel fuel droplets when atomized on a maxed out or fully modded injector?

Question 2. What size are the diesel droplets when atomized on the new power-plants?

Question 3. Does diesel get more volatile when extremely atomized?

29,000*psi (1,999 bar) high-pressure common rail Bosch fuel system on 6.7l this is the pressures that Ford is using. I do not know the pressures of the other power-plants yet. I was just trying to set up my next question. My Idea is to go another direction, fuel economy and power in an older engine. Starting with injector tips.

Question 4. How about smaller nozzles and more of them? I mean really small like half the size of a normal nozzle.

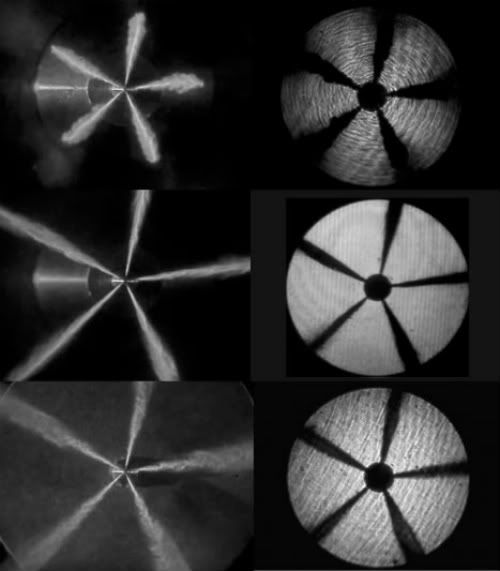

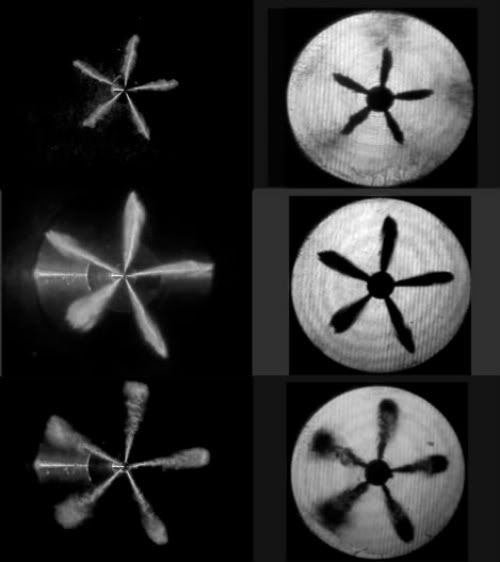

Granted we have a typical star pattern, that works well.

Question 5. How about a Cloud spray or Conical spray pattern that goes directly into the bowl, or maybe have the nozzles juxtaposition (Either against air current or with the current) in the intake swirl. I do know this is already happening in stock setting just looking to squeze mor efficency.

Now I am all for the performance and the search for more power. I just want to look at this in a different angle. I do not care if this Idea is put to good use, and that I do not make anything from it. (The manufacterers are already hip to this any way so no loss. That is besides the point (I cannot afford it anyway) might as well let somebody capitalize on this.

I know the basics about Injectors, I am just trying to see if anybody has the same Ideas. Granted I have no funds to actually do this experiment, nor the funds to process data to see the spray patterns that are actually happening in the combustion chamber. I do know that there are allot of shops out there that might. I would like some guidance please.

Forgive me for posting on a general subject everyone knows, I just want to make sure I am not stupid. I have over 150 new Ideas every day, some have to do with Mechanical, Software, Musical, and Marketing. I was told I would never be taken serious unless I have a degree. Well, I am almost done with my A/S will try to get my B/S. The unfortunate thing is I am late should have done this in my 20s. Now I am being told I am to old to be taken serious.

Thanks

Rustin

I am not out to try to Start a WAR on opinions. However; it might happen with this thread! I am just looking for guidance, and wondering if I am thinking the right way? I want to inspire out of the box thinking, without trying to reinvent the wheel (I seem to get that allot).

I want to go at it a different way. I have seen allot of injectors over the years including performance injectors, and the fuel pressures have increased, as well as injector timing. When looking back at older trucks (5.9 6bt for an example) We notice the evolution of performance injectors. First it was advance injector timing, then increase fuel pressure, followed by installing Marine injectors (after the initial intake exhaust and others, we will just considers this done throughout this post). Performance Shops discovered the weakness of the originals and started to modify accordingly. These shops and businesses are now the pioneers of diesel performance! Injector orifices were increased in size to allow more fuel (not to mention the pumps were modded to produce more fuel flow) when we start to get into black smoke that is when we are maxed out in timing, fuel pressure.

Question 1. What size are the diesel fuel droplets when atomized on a maxed out or fully modded injector?

Question 2. What size are the diesel droplets when atomized on the new power-plants?

Question 3. Does diesel get more volatile when extremely atomized?

29,000*psi (1,999 bar) high-pressure common rail Bosch fuel system on 6.7l this is the pressures that Ford is using. I do not know the pressures of the other power-plants yet. I was just trying to set up my next question. My Idea is to go another direction, fuel economy and power in an older engine. Starting with injector tips.

Question 4. How about smaller nozzles and more of them? I mean really small like half the size of a normal nozzle.

Granted we have a typical star pattern, that works well.

Question 5. How about a Cloud spray or Conical spray pattern that goes directly into the bowl, or maybe have the nozzles juxtaposition (Either against air current or with the current) in the intake swirl. I do know this is already happening in stock setting just looking to squeze mor efficency.

Now I am all for the performance and the search for more power. I just want to look at this in a different angle. I do not care if this Idea is put to good use, and that I do not make anything from it. (The manufacterers are already hip to this any way so no loss. That is besides the point (I cannot afford it anyway) might as well let somebody capitalize on this.

I know the basics about Injectors, I am just trying to see if anybody has the same Ideas. Granted I have no funds to actually do this experiment, nor the funds to process data to see the spray patterns that are actually happening in the combustion chamber. I do know that there are allot of shops out there that might. I would like some guidance please.

Forgive me for posting on a general subject everyone knows, I just want to make sure I am not stupid. I have over 150 new Ideas every day, some have to do with Mechanical, Software, Musical, and Marketing. I was told I would never be taken serious unless I have a degree. Well, I am almost done with my A/S will try to get my B/S. The unfortunate thing is I am late should have done this in my 20s. Now I am being told I am to old to be taken serious.

Thanks

Rustin

Last edited: