Smokin ACE

1st gen turbo tester

- Joined

- Aug 26, 2010

- Messages

- 250

I woke up with a wild hair this morning. Can a truck make more power in a runaway situation rather than just full throttle? Or does anyone really know?

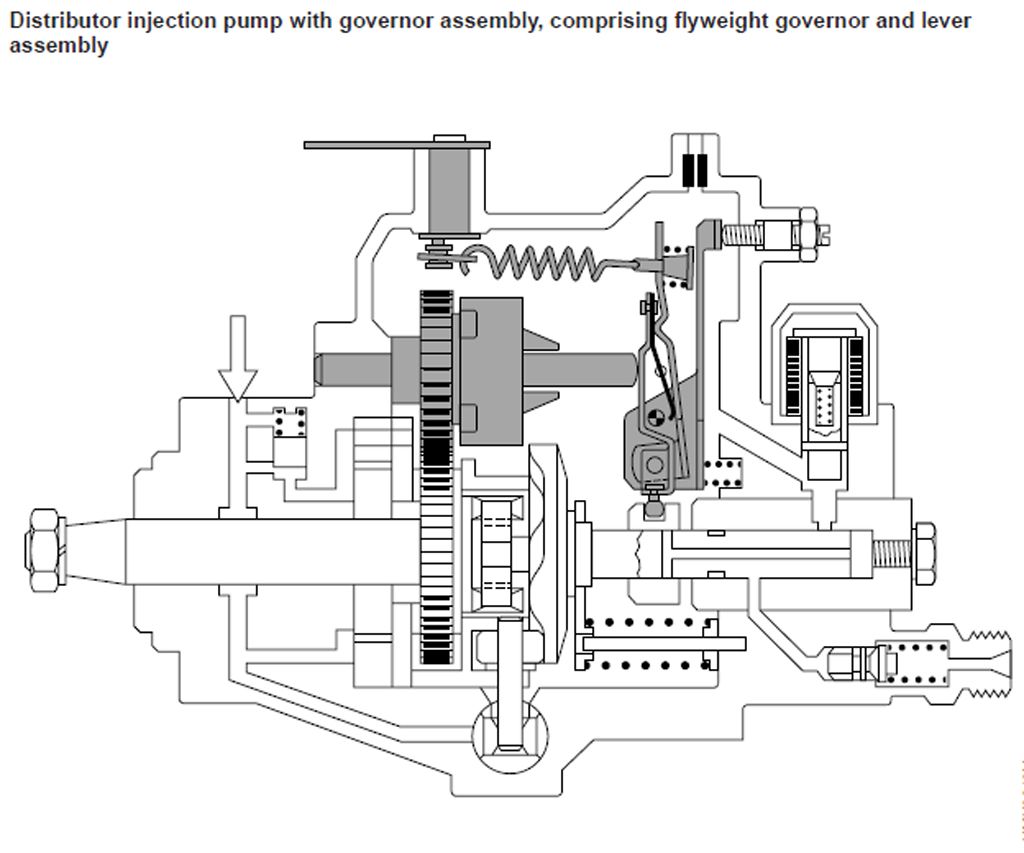

Now I know runaway is kinda scary but what exactly happens when a VE pump runs away? I've heard the governor just loses total control and just winds out til something gives, is this correct? Under a load will it still wind out to high heaven or will it find a balance?

Since VE pump runaway is so easy to reach I got to thinking. When you turn the power screw in so far the truck will "runaway", now the question is if you bring the screw back out real fast as it starts to runaway will it come back to normal? I've never personally tried it as I am usually panicking trying to get the board over the turbo as I'm sure many have been in the same boat. If it does work this way, then I thought about modifiying the power screw hole and rig up a strong actuator I can control in the cab. So in theory, in case of a sled pull or drag race (not street use of course) I could bump the actuator up to get the truck to runaway during the run then back it off as soon as the run is over with a safety button or switch on the brake pedal in case of a mishap. Thats if the theory worked and it would come from runaway back to normal. Of course I would have both fuel and air shut offs ready to be the backup plan.

Now I know this sounds kind of crazy but like I said I woke up this morning and thought "wonder if this would work" and so I thought I'd see what kind of answers I could come up with or if its a lost cause.

Now I know runaway is kinda scary but what exactly happens when a VE pump runs away? I've heard the governor just loses total control and just winds out til something gives, is this correct? Under a load will it still wind out to high heaven or will it find a balance?

Since VE pump runaway is so easy to reach I got to thinking. When you turn the power screw in so far the truck will "runaway", now the question is if you bring the screw back out real fast as it starts to runaway will it come back to normal? I've never personally tried it as I am usually panicking trying to get the board over the turbo as I'm sure many have been in the same boat. If it does work this way, then I thought about modifiying the power screw hole and rig up a strong actuator I can control in the cab. So in theory, in case of a sled pull or drag race (not street use of course) I could bump the actuator up to get the truck to runaway during the run then back it off as soon as the run is over with a safety button or switch on the brake pedal in case of a mishap. Thats if the theory worked and it would come from runaway back to normal. Of course I would have both fuel and air shut offs ready to be the backup plan.

Now I know this sounds kind of crazy but like I said I woke up this morning and thought "wonder if this would work" and so I thought I'd see what kind of answers I could come up with or if its a lost cause.