ComnRailPwr

New member

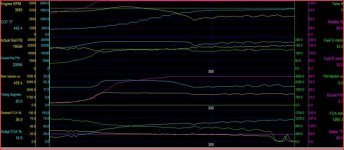

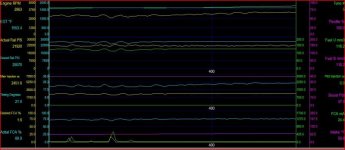

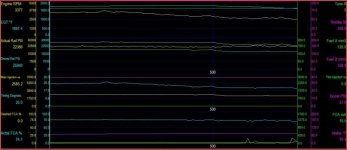

I finally got my truck done and made pull down the track. My desired vs actual rail pressure is off and it takes a very hard hit once I'm out of the clutch and never really recovers. Unfortunately the Truck is competition only and I cannot test on the road and would like to wrap my head around this pump tuning. The truck wend down the track very clean so I could use more PW to get more power but am wondering whats going on with my pumps before so. Their not keeping up but is there anything I can do in my tune. I read this thread and am kind of confused. Why is 71 the magic number for max duty cycle. What relationship does mA have With Pump flow or recovery? I'm having a stupid attack right now. So far the only FP tables I have touched are the Base and air densities. Not sure which way to go when tuning the injection pumps. The more I try to make since of desired and actual duty cycle the dumber I think I get. Any help is appreciated. Attached are some screenshots of the pull.

900-1000RWHP

Dual Pumps - stock/Floor It 3.5

200% NOZZLES

Aeromotive A1000 Fuel System @ 35psi

Here is a link to the actual Data log. CompD won't let this type of file upload. The log in this link, post #16, is in EDA format. The Tune was in CSP operating system tune #5 so you may need the latest unreleased version to view the log for those of you who got to test CSP.

FCA duty cycle questions. - Page 2

900-1000RWHP

Dual Pumps - stock/Floor It 3.5

200% NOZZLES

Aeromotive A1000 Fuel System @ 35psi

Here is a link to the actual Data log. CompD won't let this type of file upload. The log in this link, post #16, is in EDA format. The Tune was in CSP operating system tune #5 so you may need the latest unreleased version to view the log for those of you who got to test CSP.

FCA duty cycle questions. - Page 2