79fordcrew

Banned

Would a 362sxe over a 369sxe be a good compound setup or are they two close in size. I would think it would spool crazy fast. Also if it would work what kind of power would it support.

Look at power driven diesels video of their towing compounds using the s369 as the primary. Iirc, they did 690 hp.

Would it flow enough to support 800 to say a 1000hp. Definitely not saying that's my goal. But also don't want to buy turbos two or three times. Truck is driven daily and I like drag racing so I like the idea of fast spoolup. Just wondering if it would flow the air to support those numbers.

With a 25% correction factor......

Absolutely not.....

An s480 or comparable primary. A smaller s362/68 will work but it is going to require an external gate.

And wouldn't the k27 limit airflow on power drivens compound setup? Just thinking out loud here.

I completely agree with your 7hp/lb generally speaking for a 12v. I made 824hp flowing ~120lbs and 964hp flowing ~140lbs (both uncorrected). But, I couldn't check the actual mass flow. Everything was calculated based on rpm/pressure/air temp with a guesstimated VE of 90%.

But I'd also like to point out, that there are 80mm wheels for a s480 that flow a lot more than 120lbs. So while it's not likely you'll hit 1000hp with a stock s480, it's not impossible to hit it with a 80mm turbo. Good luck though.

We recently dyno tested a 369sxe single vs. 366sxe single same-day, same-fueling, same-turbine housing on my Junker Drag Truck, and we ended up with a 6% peak power difference, not the flow map predicted 14% difference. Next round of testing will be with a larger exhaust housing setup and T4 manifold to test the theory that turbine flow is somewhat limiting the 369sxe and not allowing it to make the full 14% increase over the 366sxe.

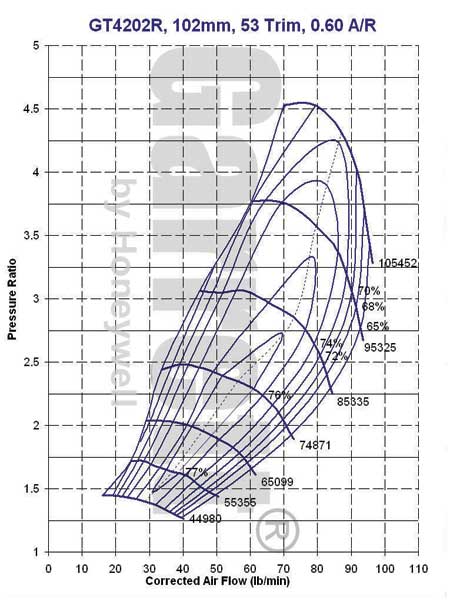

What about a gta4202 would it flow enough to support 1000hp under a 62

Why would you assert that our 690 HP dyno pull had a 25% correction factor and therefore absolutely will not support 800 to 1000 HP, then later post that an S480 or comparable primary will support the 1000 HP power goal?

By your math, our 690 HP after a 25% reduction = 552 raw HP from the "poor flowing" 369sxe that roughly flows 100 lbs per minute.

So using your math, the S480 which roughly flows 120 lbs per minute or 20% more should support a whopping 662 HP or nowhere near the original poster's power goal.

Free internet-based education is just that, free. Real education comes from hours of testing, studying reliable materials, and reflection/pondering the data, creating theories, then more testing. I will admit that I enjoy reading internet based data and power numbers from other shops, other dynos, and other trucks. It is fun to bench race dynos, compare numbers, compare time slips, etc. At the end of the day, testing turbos on the same truck with the same dyno is the best way to see trends and gather data to form theories and project power numbers.

This is internet advice, so take it for what it's worth, we generally see 7hp raw "uncorrected" at the tire per LB of air moved by the turbo on a mechanical injection 12v cummins and 8hp raw "uncorrected" per LB of air moved by the turbo on a well-tuned common rail. These are attainable realistic numbers that most trucks can achieve.

For 1000 HP on a 12v Cummins, we'd recommend a turbo system capable of 142 lbs per minute

For 1000 HP on a Common Rail, we'd recommend a turbo system capable of 125 lbs per minute which is still a little larger than an S480. Not that a few perfectly tuned common rails haven't hit 1k HP with an S480 spun off the map, just that you really need 125 lbs per minute to do it reliably on most trucks.

Are we implying that the S369 is a more capable turbo than the GTA4202/gt4202 ?