SWALLDOG

Member

- Joined

- Jun 18, 2008

- Messages

- 454

so after a week of working on my truck and getting it handed to me i finally got it all together. just thought i would share.

so i got a new header from a member off the cummins forum for a sweet deal. i wasent really in the market for it but it was a good deal. well i got it a week before the industrial injection dyno event and thought i could have it on by then.

so i get the truck all taken apart and find out that the header does not fit when ya flip it upside down. the tubes hit the mount for the engine oil filter! which is why i prolly havent seen any of these headers upside down for twins. :bang guess i didnet get the memo.

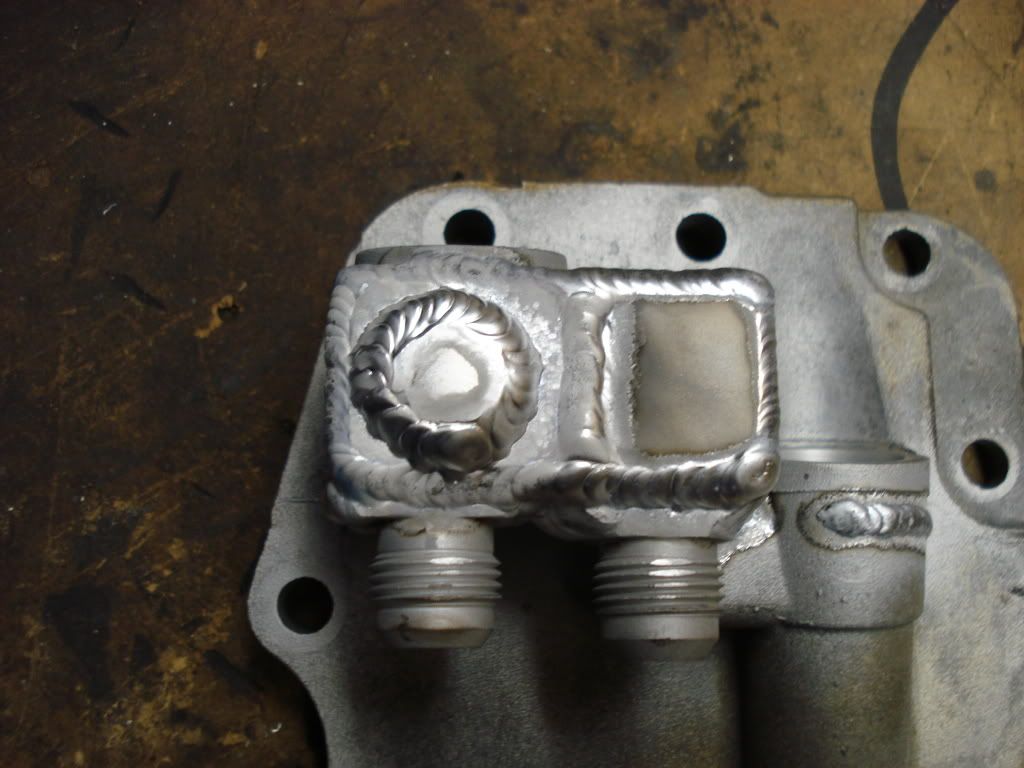

well i figured that i could make it work. little modifications here and there, some cutting, some welding and we would be good to go. turned out to be a little more than that. and on top of that when i took it all apart found out that my waste gate port on my top turbo was all cracked up. which is why it was takin forever to spool up. but thats a whole other story all together.

so i got a new header from a member off the cummins forum for a sweet deal. i wasent really in the market for it but it was a good deal. well i got it a week before the industrial injection dyno event and thought i could have it on by then.

so i get the truck all taken apart and find out that the header does not fit when ya flip it upside down. the tubes hit the mount for the engine oil filter! which is why i prolly havent seen any of these headers upside down for twins. :bang guess i didnet get the memo.

well i figured that i could make it work. little modifications here and there, some cutting, some welding and we would be good to go. turned out to be a little more than that. and on top of that when i took it all apart found out that my waste gate port on my top turbo was all cracked up. which is why it was takin forever to spool up. but thats a whole other story all together.