jfaulkner

Douche Hunter

- Joined

- Sep 24, 2007

- Messages

- 5,864

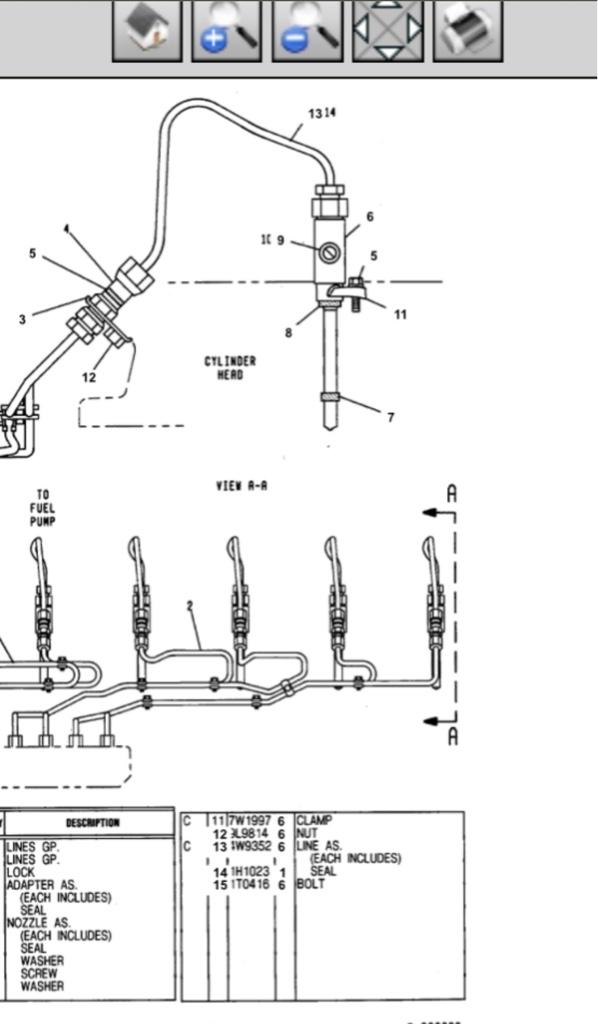

Adapter was to convert a PC head to DI. He wanted to build an 18L mechanical with 13mm Cat pump. After reading all the cons of using those parts the idea was scrapped. The block would be OK but since you would have to change a lot of stuff to make it DI it would be cheaper to just start with a DI engine. I think timing advance was different and probably more. I’ve never seen one other than this one so he’s probably right about not being used in trucks but.....

This particular block and head was part of the 88,000#+ worth of engine parts me and some friends bought. The heads look the same as any 3406A/B other than the injector holes being larger. SmokinCat looked all this up when we were digging to try and make this work and it’s just not worth it.

This particular block and head was part of the 88,000#+ worth of engine parts me and some friends bought. The heads look the same as any 3406A/B other than the injector holes being larger. SmokinCat looked all this up when we were digging to try and make this work and it’s just not worth it.