bgreen776

White Collar Fabricator

- Joined

- Jul 12, 2012

- Messages

- 578

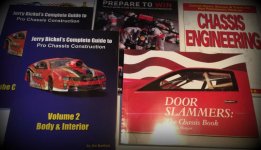

I'm surprised, but it looks like I can get 1-3/4 x .095 4130 tubing up here for less than $7/foot. I wonder how light can a guy build a full size truck without spending big money on carbon fiber body panels and the like?

4500 lbs sounds fairly reasonable.

4500 lbs sounds fairly reasonable.