JFlagg

Gun for Hire

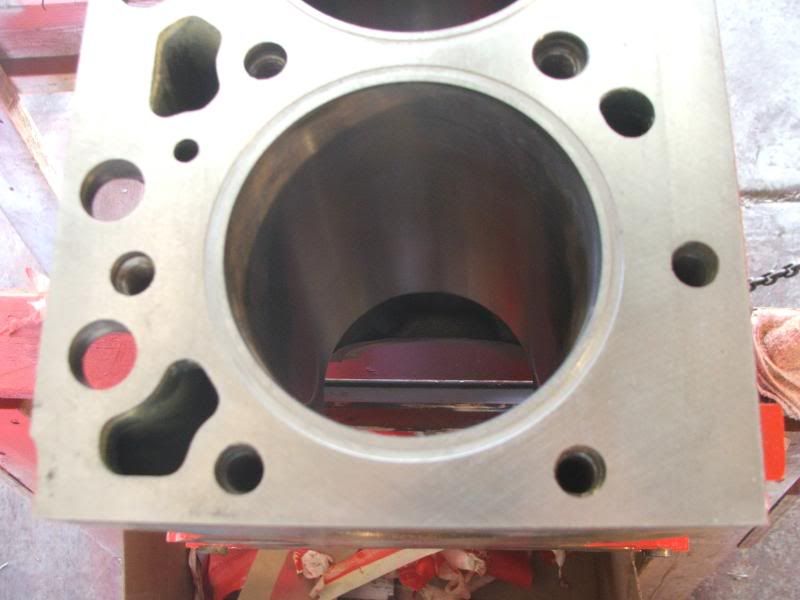

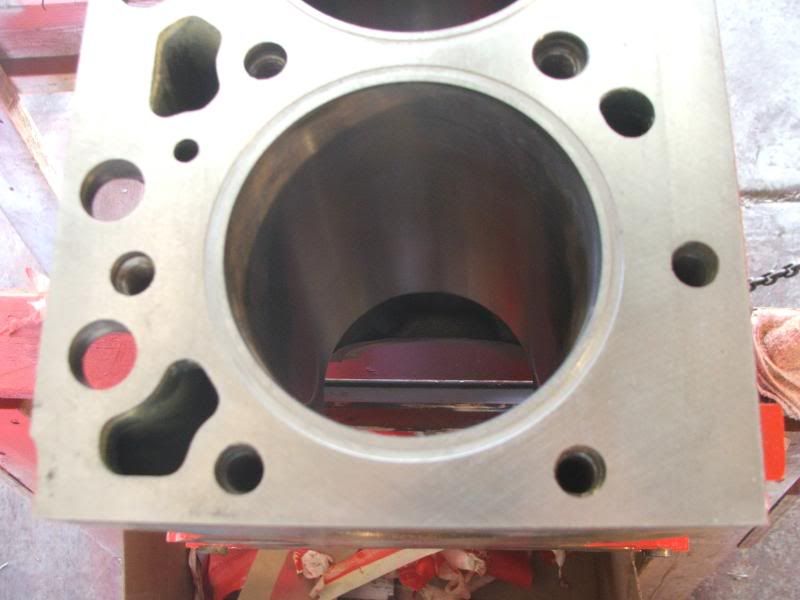

:shake:Finally got he head and block back from the machine shop... only to have to take it elsewhere to get the firerings cut since the machine shop I went to didn't do that...:doh: Either way, thanks to Phase 2 machine in STL for getting it finished and MCS Diesel for fire-ringing it for me. :rockwoot: I painted yesterday so I could start putting it together this week hopefully... Hope the color choice is OK with everyone... Not like your opinions matter to me since its my truck :shake: Here is what I have so far....

And before everyone starts telling me the block looks orange... it is RED. Regular old Rustoleum Apple Red, LOL Though, I admit, the pics look a bit orange. All the bolt ons will be Rustoleum Metallic Gray... just slightly darker than my truck. The red and gray should look good together IMO.

And before everyone starts telling me the block looks orange... it is RED. Regular old Rustoleum Apple Red, LOL Though, I admit, the pics look a bit orange. All the bolt ons will be Rustoleum Metallic Gray... just slightly darker than my truck. The red and gray should look good together IMO.