The CF thread is awesome...lol. All of the product support based on "I have a whole 4,000 miles on them and they are fine"...blah blah blah. Million mile pistons being verified by 4,000 mile injector tests.

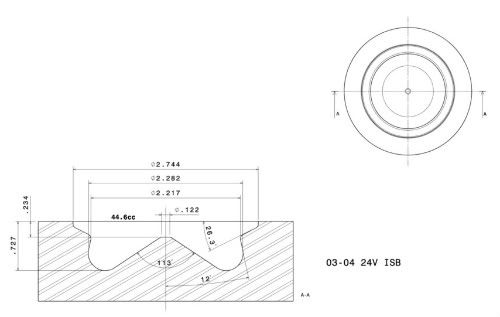

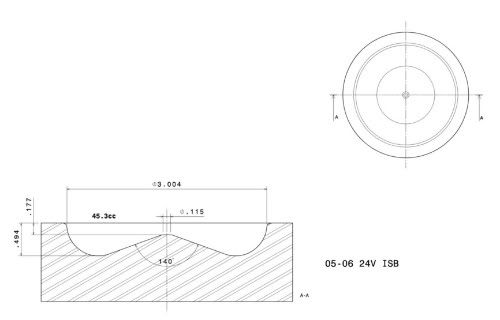

Match the angle to the piston...don't drink the cool aid.

I said DDP because they at least don't mismatch bowl and spray angle design.

Match the angle to the piston...don't drink the cool aid.

I said DDP because they at least don't mismatch bowl and spray angle design.