dickshaker

The real sled watcher

- Joined

- Dec 26, 2009

- Messages

- 66

^^^ LOL typical dtr unicorn truck and operator.

^^^ LOL typical dtr unicorn truck and operator.

You clearly have no knowledge of me. STFU

There is nothing unicorn about it. You more than welcome to witness anything yourself...or talk to the many that can personally vouch.

Lets get back on topic..yes?

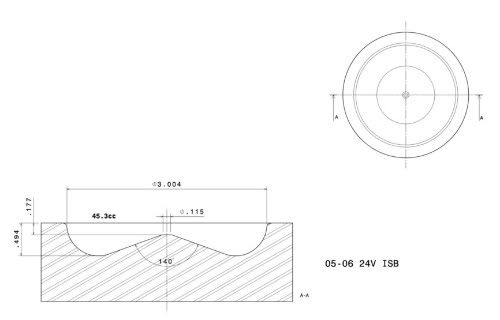

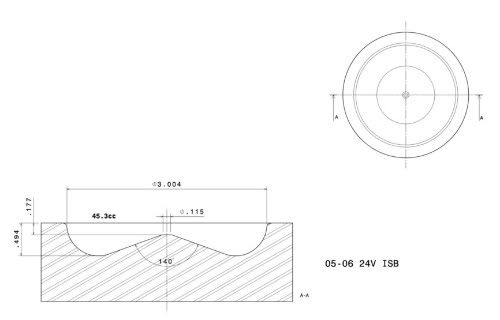

So...if the idea behind narrow spray angle in wide bowls was to promote cleaner burn...ie less emissions for the 4.5-07 pistons...and switching to wide spray angle in the wide bowl produces more power (even if it is a short term solution), what happens then you fire the same pulse width, pressure, and optimized timing at a piston bowl that was designed for a wide spray pattern?

Less power?

Why you asking us? You're the one that said Cummins knows best, ask them.

80k lbs through the Rockies at 1000hp making 100lbs of boost. His truck can do things no other can do. Didnt you know that by now. It's all he spats off about on here.

So back to late model re-entrant pistons and different spray angles.

Tapamaxxing

My question is why with the narrow spray angle on a wide bowl does it seem that most melt downs are on the outer edges of the piston?

Those are the rattle trucks...fuel is making it all the way out there because the piston is too low in the stroke.

Don, do you see these same issues in new or remans coming directly from Bosch?

I did it because I was bored, and I like math. I don't have the distance for how far below the head surface the tip of the injector is or the air gap between the top of the piston and the head. All that said, here's what I came up with. A 124 degree spray angle will spray right at the edge of the bowl when the timing is at 26.5 degrees. A 143 degree spray angle will spray right at the edge of the bowl when the timing is at 21.5 degrees. For curiosity's sake, I checked when the spray would hit the cylinder wall. With the 124 degree spray angle, it will hit at 31 degrees of timing, and with the 143 degree spray angle, it will hit the cylinder wall at 25 degrees of timing.Do the math on how much timing would need to be used to spray on top of the crown in a 3" bowl with a 124° cone angle and you will quickly realize that is not the issue.

Yes we have tried other manufacture's and other angles, nothing has been within 400hp of the exergy stuff.

I did it because I was bored, and I like math. I don't have the distance for how far below the head surface the tip of the injector is or the air gap between the top of the piston and the head. All that said, here's what I came up with. A 124 degree spray angle will spray right at the edge of the bowl when the timing is at 26.5 degrees. A 143 degree spray angle will spray right at the edge of the bowl when the timing is at 21.5 degrees. For curiosity's sake, I checked when the spray would hit the cylinder wall. With the 124 degree spray angle, it will hit at 31 degrees of timing, and with the 143 degree spray angle, it will hit the cylinder wall at 25 degrees of timing.

I did it because I was bored, and I like math. I don't have the distance for how far below the head surface the tip of the injector is or the air gap between the top of the piston and the head. All that said, here's what I came up with. A 124 degree spray angle will spray right at the edge of the bowl when the timing is at 26.5 degrees. A 143 degree spray angle will spray right at the edge of the bowl when the timing is at 21.5 degrees. For curiosity's sake, I checked when the spray would hit the cylinder wall. With the 124 degree spray angle, it will hit at 31 degrees of timing, and with the 143 degree spray angle, it will hit the cylinder wall at 25 degrees of timing.

I did it because I was bored, and I like math. I don't have the distance for how far below the head surface the tip of the injector is or the air gap between the top of the piston and the head. All that said, here's what I came up with. A 124 degree spray angle will spray right at the edge of the bowl when the timing is at 26.5 degrees. A 143 degree spray angle will spray right at the edge of the bowl when the timing is at 21.5 degrees. For curiosity's sake, I checked when the spray would hit the cylinder wall. With the 124 degree spray angle, it will hit at 31 degrees of timing, and with the 143 degree spray angle, it will hit the cylinder wall at 25 degrees of timing.

Utilizing the 143° marine nozzle would put the pattern on the edge of the lip at roughly 45° advance on the piston above.

It is nice to see someone else actually put in the effort and try.

Static Timing Advance is only a part of the equation...What PSI is this calculation being derived from? I figured between 50-60* advance given 28k RP

Thats a large margin...sure everything was apples to apples?