kawi600

got Coal for Christmas

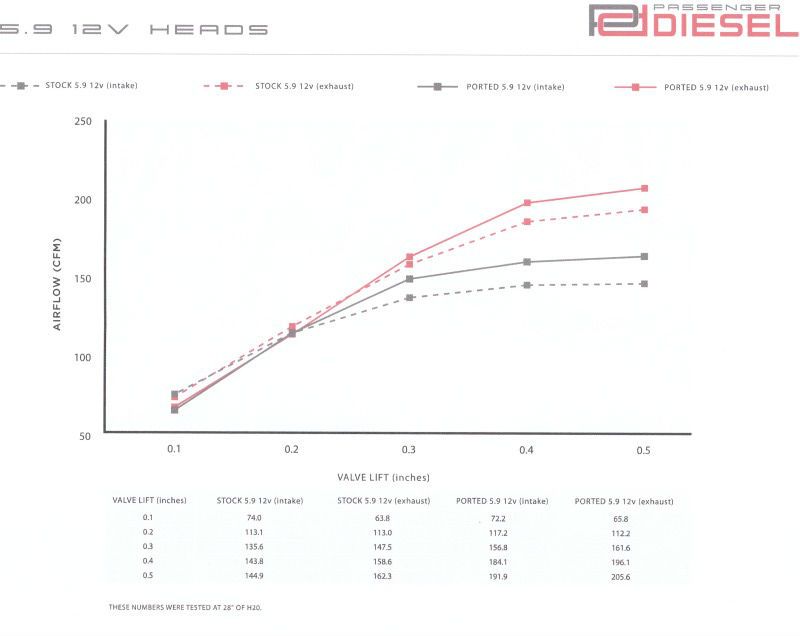

I just had my cylinder head swapped back from Zach's 12v head to an OE cummins one. I had Zach deck the head to lower the valves and add some swirl reliefs to the intake valves. That head showed 380PSI on my truck. Same as a stock setup with .020 oversize gasket.

With the hamilton unit, the spool and top end was nice, but part-load operation was awful. I had thick idle smoke and off the line Id smoke the people behind me. Dialing this out with the AFC wasnt possible without making it undriveable.

Fueling stayed the same.. turbo was not changed. The only thing that really changed is the port and valve sizes. My guess is that swirl (from higher intake speed) is the real change.

FYI if anyone is considering a ported head on any daily driver truck. The only way to (maybe) have your cake and eat it too is with a supercharger to make up for the change in port velocity.

With the hamilton unit, the spool and top end was nice, but part-load operation was awful. I had thick idle smoke and off the line Id smoke the people behind me. Dialing this out with the AFC wasnt possible without making it undriveable.

Fueling stayed the same.. turbo was not changed. The only thing that really changed is the port and valve sizes. My guess is that swirl (from higher intake speed) is the real change.

FYI if anyone is considering a ported head on any daily driver truck. The only way to (maybe) have your cake and eat it too is with a supercharger to make up for the change in port velocity.