jcarrick

New member

- Joined

- Nov 7, 2012

- Messages

- 137

Hey guys,

I went to update my old thread and found that it was closed so I figured I'd make a new one. My truck is a 1997 F350 CCLB with a 215 P-pump 12 valve cummins mated to a ZF5 and has been converted for the last 50k miles. Heres a pic of the truck currently:

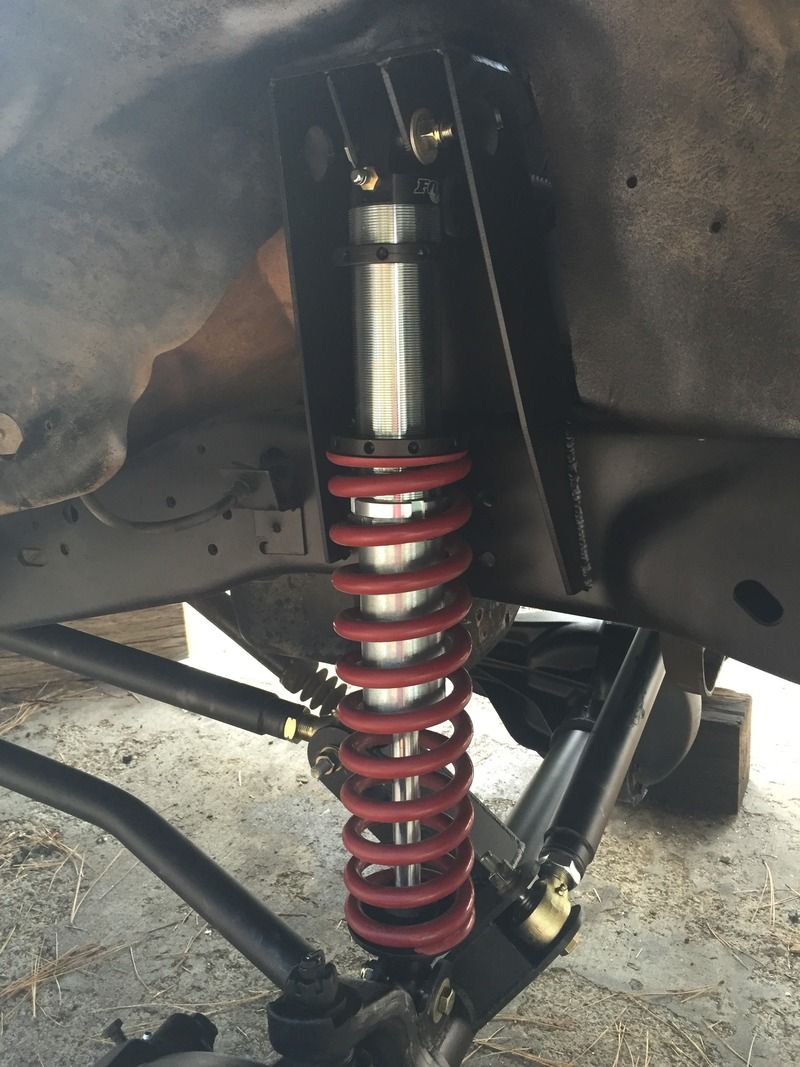

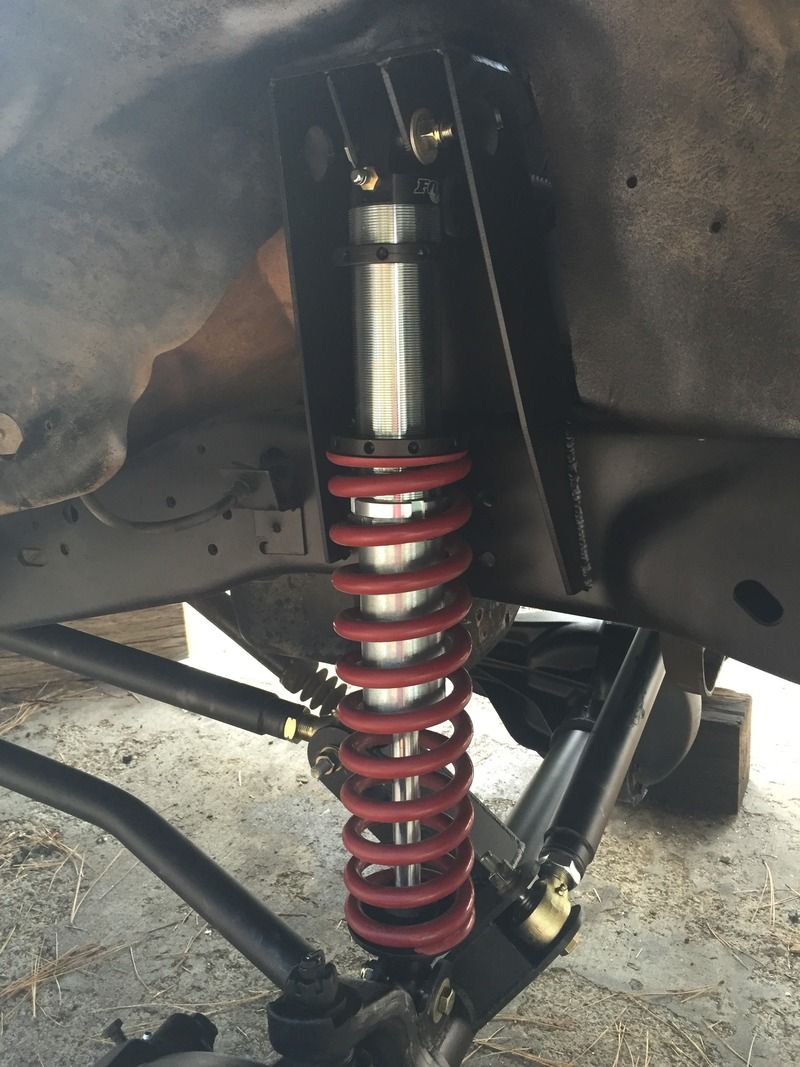

For the past year I have been working on developing high end aftermarket products for OBS Fords and have been using mine as truck to test everything out on. I just finished a 3 link front end with coilovers that we are turning into a kit for other OBS owners. Here are some of the pics of that stuff:

Right now it is just on some tester springs, but the final springs just came in from Eibach on Monday. This setup rides and drives amazingly! Everything is tig welding and cut with a CNC plasma table.

Here are some of future plans for this pickup:

-Dodge AAM 11.5 rear end with self leveling airbag/link setup in the rear.

-Twins turbos. I already have an HT3B 23cm ready to install, just havent had the time. Looking for a cool (temp wise) 450-500hp for towing.

-Subframe that will reduce the crazy frame flex these trucks have. I am meeting with a mechanical engineer for coming up with a good design that wont lead to cracks in other areas of the frame.

I am sure I am forgetting a ton, but I figured I would share with you guys and see what you think! :Cheer:

-Jon

I went to update my old thread and found that it was closed so I figured I'd make a new one. My truck is a 1997 F350 CCLB with a 215 P-pump 12 valve cummins mated to a ZF5 and has been converted for the last 50k miles. Heres a pic of the truck currently:

For the past year I have been working on developing high end aftermarket products for OBS Fords and have been using mine as truck to test everything out on. I just finished a 3 link front end with coilovers that we are turning into a kit for other OBS owners. Here are some of the pics of that stuff:

Right now it is just on some tester springs, but the final springs just came in from Eibach on Monday. This setup rides and drives amazingly! Everything is tig welding and cut with a CNC plasma table.

Here are some of future plans for this pickup:

-Dodge AAM 11.5 rear end with self leveling airbag/link setup in the rear.

-Twins turbos. I already have an HT3B 23cm ready to install, just havent had the time. Looking for a cool (temp wise) 450-500hp for towing.

-Subframe that will reduce the crazy frame flex these trucks have. I am meeting with a mechanical engineer for coming up with a good design that wont lead to cracks in other areas of the frame.

I am sure I am forgetting a ton, but I figured I would share with you guys and see what you think! :Cheer:

-Jon