.

. Again, you think the same principles fit every appication.

The reality is that I use the same principals on every engine program. There are four basic points that truly matter in a cam development program. life is dictated by cylinder head flow, and agressiveness of the profile is based on the engine use.

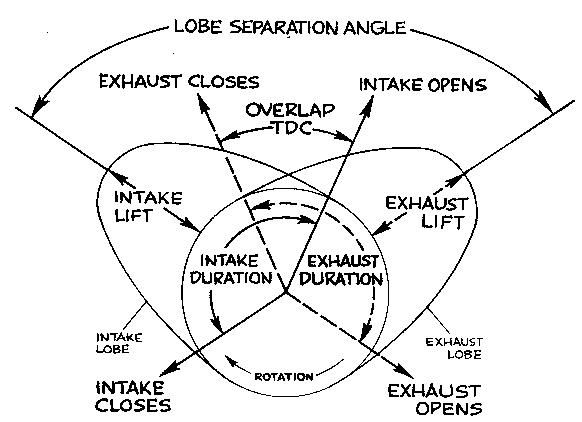

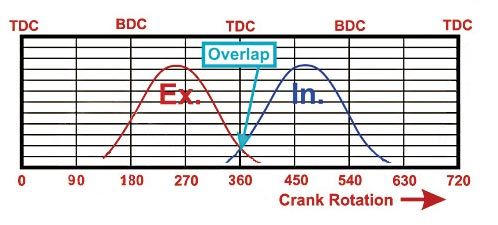

The open of the intake event, close of the intake event, open of the exhaust event and closing of the exhaust event.

I evaluate what a particular cam program is doing in the application. I make changes based on dyno time, and performance on the track, or pull. When I make the decision that the engine wants something different, then I make changes to one event, usually the intake closing event.

So let look at your theories that only one LSA (108) is valid in a diesel.

Let’s start with a base line grind that I start with a particular cylinder head, turbo charger program.

Let’s say it runs really good, takes up throttle really good down low spools the chargers easly , and moves air really good. Let’s say it has a 210 intake event on a 108 LSA the cam is in at 105 intake lobe center line. We like what the exhaust is doing so we leave it alone.

The only event let's change is the closure of the intake event. Lets close the intake valve 20 degree later. this allows the motor to capture more air at higher rpm's

So its basically the exact cam with the exception your leaving the intake open longer, wow the LSA is now 113, and the intake lobe center line is now 115.

Do this 10 times on a engine dyno, which I’ve been doing, and you will learn a lot about what a pedicure engine wants.

I see some of my cams this time next year being on 12o or 122 LSA.

oke: