jimbo486

New member

- Joined

- Jan 24, 2010

- Messages

- 1,617

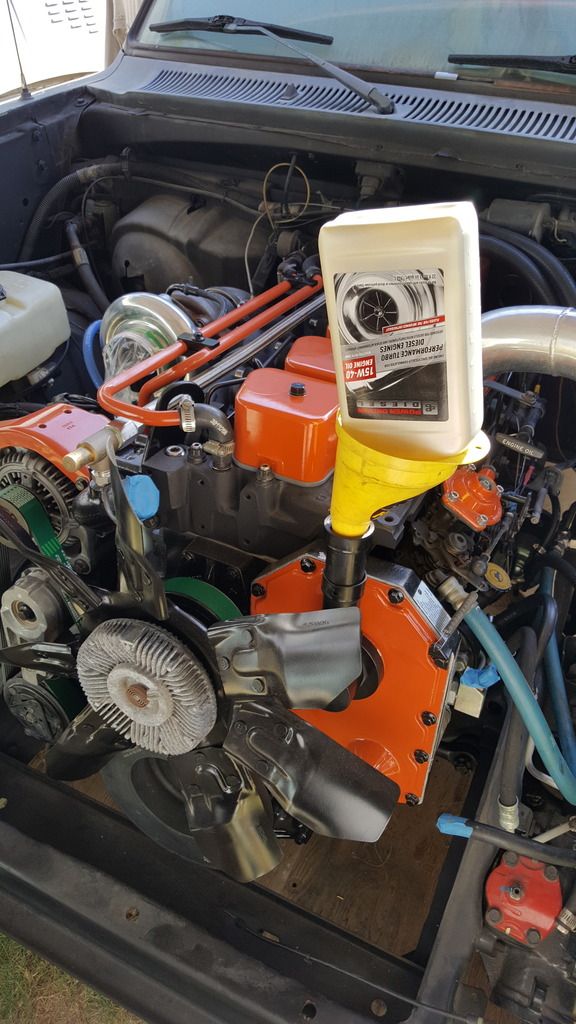

Hung the turbo, installed the heater core supply and return tubes/hoses and mounted the A/C compressor.

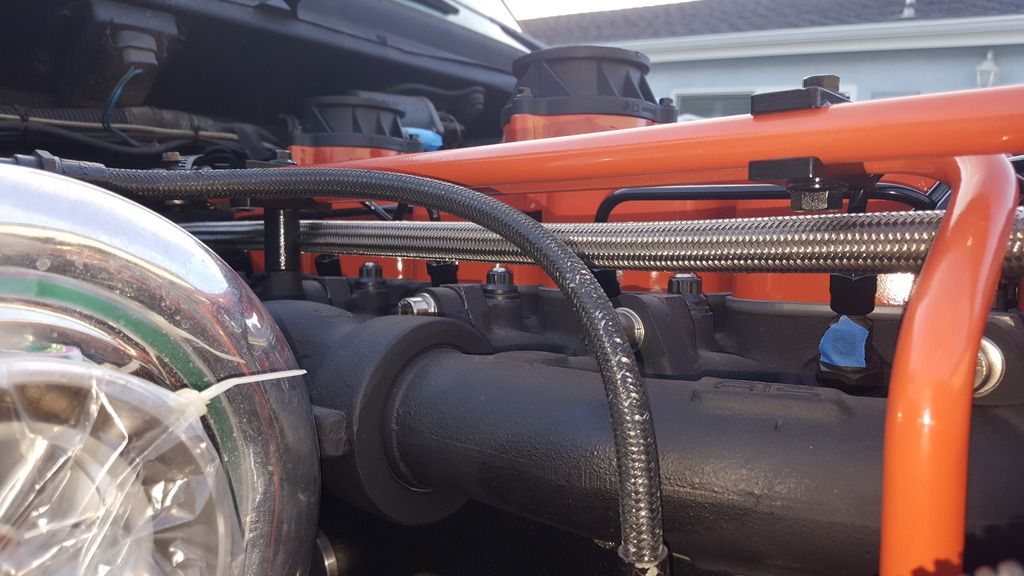

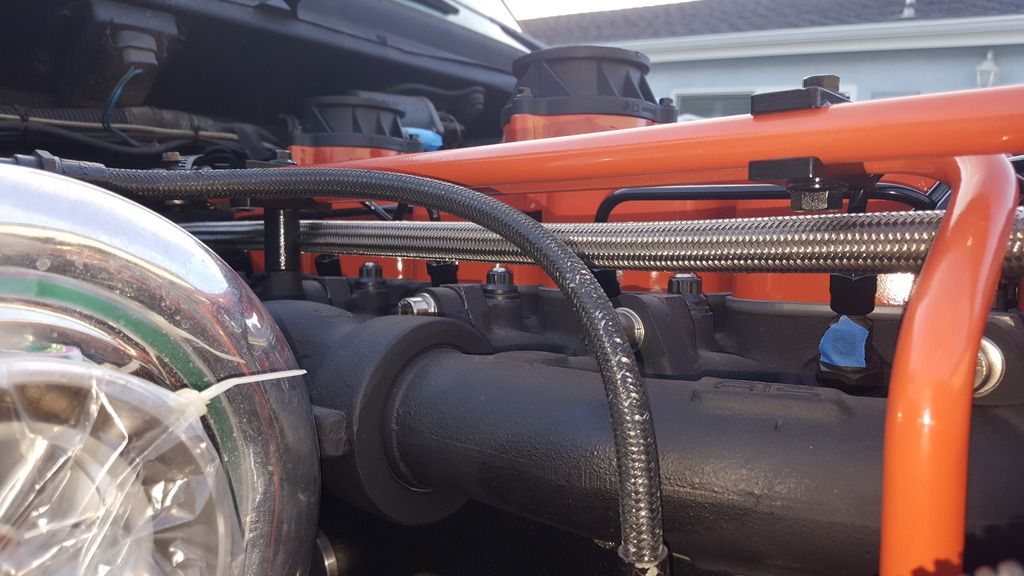

The braided hose for the bypass line lays exactly where I intended it to.

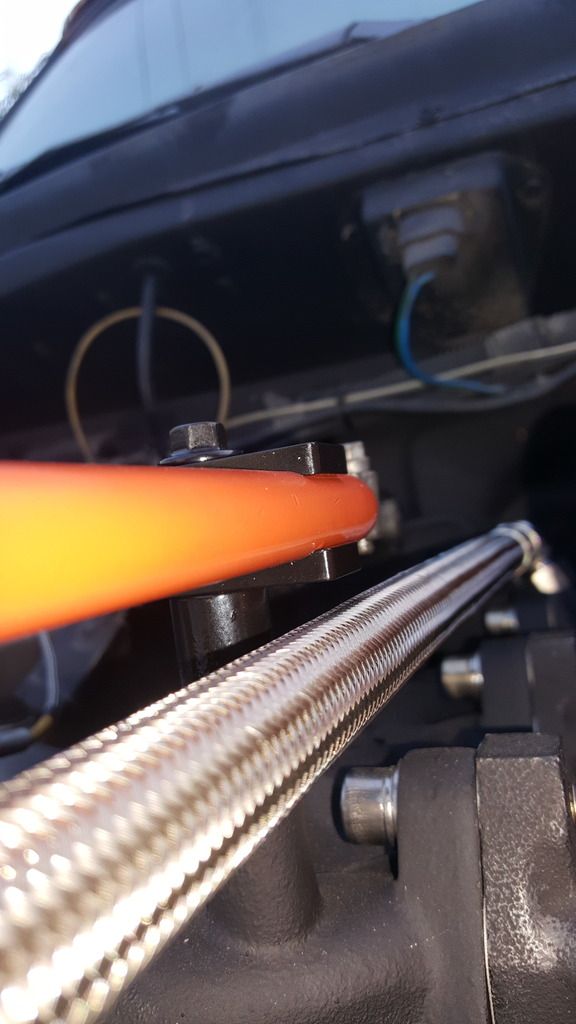

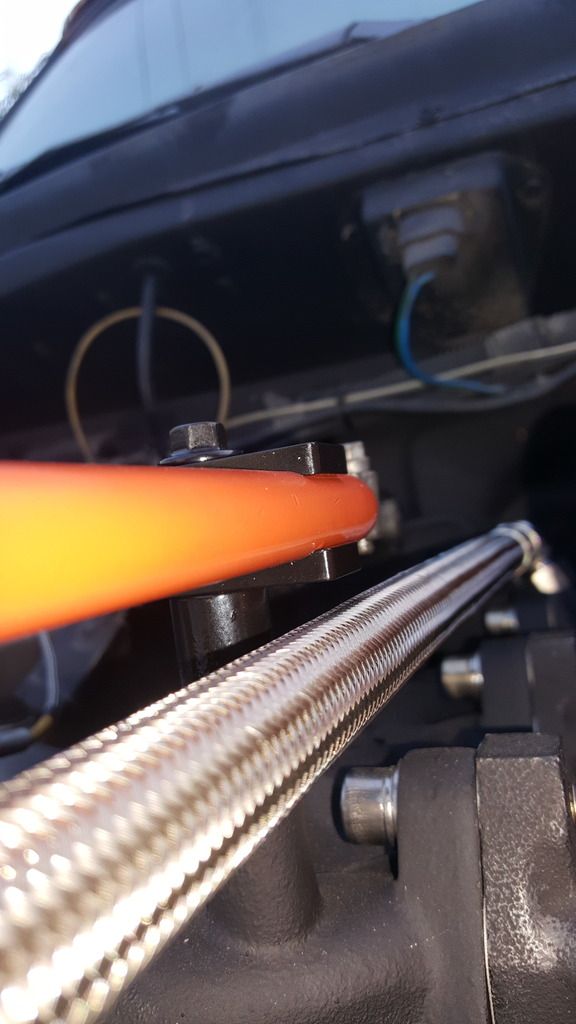

I tried to make one of these clamps work between the rear tubing clamp and its stand-off on the exhaust manifold. However, the OD of the braided hose was too large. I can make one of the proper length out of some thin gauge flat stock in the future. The hose has a very small amount of slack in it but not enough to move much or vibrate against anything near it.

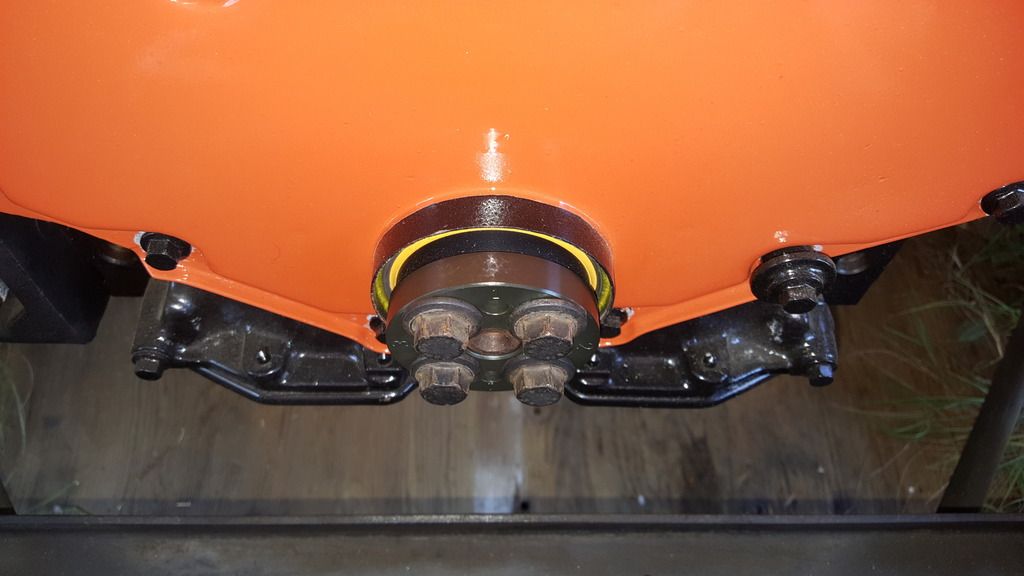

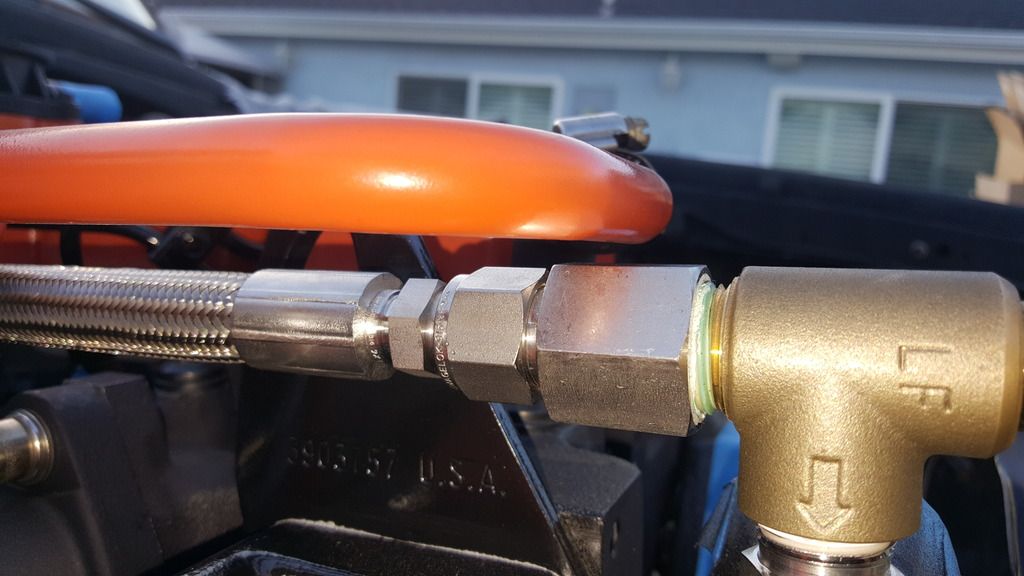

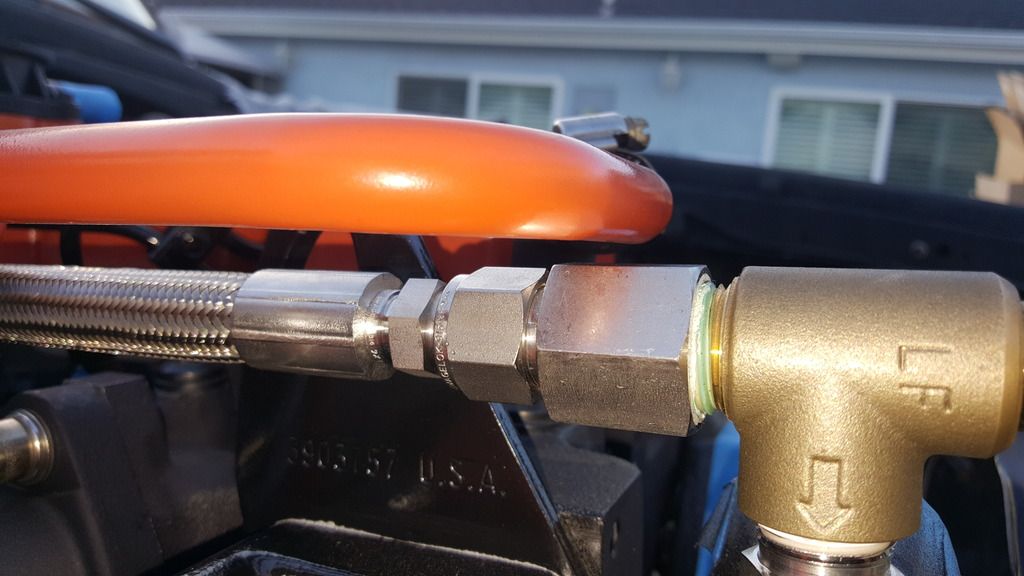

Situated the heater core tubes at just the right height to clear the PRV.

Still enough room to get wrenches on the fittings.

Finally, I decided to buy an engine pre-oiler kit. Found a Summit special for $160. 2.5gal capacity with a 6ft braided hose. I can justify that price for my peace of mind about getting oil to the main rifle and all the passages to the main and rod bearings, etc.

The braided hose for the bypass line lays exactly where I intended it to.

I tried to make one of these clamps work between the rear tubing clamp and its stand-off on the exhaust manifold. However, the OD of the braided hose was too large. I can make one of the proper length out of some thin gauge flat stock in the future. The hose has a very small amount of slack in it but not enough to move much or vibrate against anything near it.

Situated the heater core tubes at just the right height to clear the PRV.

Still enough room to get wrenches on the fittings.

Finally, I decided to buy an engine pre-oiler kit. Found a Summit special for $160. 2.5gal capacity with a 6ft braided hose. I can justify that price for my peace of mind about getting oil to the main rifle and all the passages to the main and rod bearings, etc.