If you thought the plane on the treadmill was bad.. Wait till we dive into this.

The following is entirely my opinion. Feel free to disagree, but I would love an educated explanation with data as a response. If you’ve got a claim otherwise, back it up.

Little background on this post: I’ve been reading for a while that a dual disk clutch will cause your transmission to shift slower than a regular single disk clutch. When I first heard this, I decided to take it at face value and go with it. However, when I decided to purchase my first dual disk clutch, it became a large concern.

Unable to find an explanation as to why a dual disk clutch would shift slower, I let the issue drop and installed a Haisley Street Drag.

A funny thing happened though: I noticed 0, and I mean zip, zero, nadda, difference in shift speed. Why is that?

So, I started to question the folks that claimed a dual disk would shift slower. I wanted specific answers, backed by data. At worse, I got the typical “it just does.” At best, I folks theorized that the increased inertia from added material (and weight) would cause slower shifting. The real question is… Does it?

I figured I could probably gather a little information from google about slow shifting dual disk clutches. Problem is, we diesel folks seem to be the only ones that complain about slower shifting. Most forums and magazines praise the dual disk as a great, yet expensive, upgrade to your vehicle. Lower pedal pressure with higher holding power. But, in all of my searches, I’ve yet to find a non-diesel example of slower shifting after installing a dual disk clutch.

Let me google that for you

There are also examples of high-performance OEM vehicles coming with a dual disk clutch. Most noticeably, the Honda NSX was offered with a dual disk from 1991-1996. These cars redline at over 8,000rpm. This is an important fact that I will get to later, but just keep it noted for now. The goal of the dual disk clutch was to “improve clutch engagement and smoothness.” No mention of slower shifting or reduced 0-60 / ¼ mile times because of it:

Wikimedia Error

I guess it boils down to this: “what changes during a dual disk clutch install, and why would folks believe their transmissions shifted slower after?”

Most folks probably get how a manual transmission works. I love this site for pictures and descriptions of what’s going on:

HowStuffWorks "Fly Wheels, Clutch Plates and Friction"

So in stock form, a single pressure plate pushes a single clutch disk against a single flywheel.

In the dual disk clutch, we are adding an additional clutch disk and a floater plate. Does the pressure plate FUNCTION change in any way? No. It functions exactly the same as a single disk clutch.

So, if we have 2 pressure plates, and they are both rated at 3000 pound plate load, what is the difference between them? Nothing!

Is there a difference if the pressure plate is pushing on 1 clutch disk, or 2 (and a floater plate)? No. We have just doubled the amount of clutch material. Does this increase weight? YES. And THAT is where the changes are occurring.

The flywheel and floater plate are spinning at exactly the same speed. On the Haisley, the float plate was bolted to the flywheel. On the south bend, the floater plate sits inside large grooves cut in the outside rim of the flywheel. In either case, the flywheel and floater plate cannot move independent of each other (if they are, something broke).

The clutch disks are splined to the transmission input shaft. Once again, they cannot spin independent of each other, unless the splines break.

So on a single disk, the pressure plate pushes against the clutch, which pushes against the flywheel. Pretty simple.

Dual disk, the pressure plate pushes against the clutch, which pushes against the floater plate, which pushes against the second clutch, which pushes against the flywheel. Floater plate and flywheel are moving at exactly the same speed (on the Haisley it is bolted in place, on the South Bend the grooves hold it) Clutches are moving at exactly the same speed (splined to the transmission input shaft). There is no change in function.

There are 3 changes we are dealing with:

1: Pressure

2: Material

3: Weight

Lets start with pressure:

Increased clamping force from the pressure plate generally translates to increased pedal pressure. The function is identical, the “feel” is not, whether it is a single disk or a dual disk. Increased pressure plate clamping force causes 2 issues:

1, more “work” for the hydraulics (ie, higher pressures exerted back to the master cylinder.. This is why we blow out the stock hydraulics. They are asked to hold more pressure than originally designed).

2, more “work” for our leg. Once again, on either a single disk or a dual disk clutch, increased clamping force will generally increase pedal pressure. The manufacturers say so right on their websites, usually describing it as “slight increase over stock.”

Do either of these 2 increases in work explain “slower shifting?” No!

Let just step away from clutches for a second and compare it to anything else in life.

Lets say we have a machine that requires we push a lever with our legs. The travel distance is exactly the same for every person (we will say, 8 inches), but you can very the weight required to push the lever. I can push 2 pounds in 1 second. Bob can push 2.5 pounds in 1 second. Jim can push 2.2 pounds in 1 second. Frank can push 3 pounds in 1 second.

Which of us is pushing the machine the fastest? None of us (or all of us). It is exactly the same. You see, the machine does not care that we increased pressure. It functions exactly the same. 1 second is 1 second is 1 second.. No matter if it is 1 pound or 100.

The clutch is no different, (unless you believe you can push the clutch so hard that the hydraulic fluid changes properties depending on how much pressure is exerted against it from the pressure plate…) The clutch travel distance does not change (engagement points may, but we will cover that later also.) It does not matter, whether you are using a single disk, a dual disk, a quadruple disk: the travel distance of the clutch pedal does not change. The question is, can you push the clutch pedal to the floor? Yes. If you can push it to the floor, can you push it at the same speed every time? What if we increase the workload required to push the pedal to the floor. What does it change? Only the amount of pressure required to depress the clutch pedal. Distance does not change.

So, if you can press the clutch pedal to the floor in exactly 1 second with 2 pounds of pressure pushing against your foot, are you moving any slower if you can push 2.5 pounds of pressure to the floor in exactly 1 second? No. Does it take an increase in energy? Yes. The increase is in your muscles. You are asking them to do more work at the same speed. Is that humanly possible? At the weights we are dealing with when it comes to pedal pressure, you damn well better believe it is. So knowing that the hydraulic fluid is a constantly, that the distance the fluid travels is a constant, that the distance the pedal travels is a constant, and the speed at which the pedal travels is a constant.. Is there any difference between a single disk and a dual disk? No. There cannot be.

2: Material.

Can material change how fast a clutch shifts? Yes! Does it make a big enough difference that we are going to notice? Doubtful. Now, I’m not speaking for any of the clutch manufacturers here. But, I’m going to theorize. Here is my theory: the 12cb dual disk clutch from South Bend uses different material than the 6cb clutch. I’m also betting the old Haisley Street Drag 6cb dual disk used a different material than their new one. Can this change how “fast” the clutch shifts.. Minimal, minimal amounts. How? A grabbier material clutch is going to shift “quicker” than an organic (or not as grabby) material clutch. It has nothing to do with pressure plate speeds (as described above) or weight (as described later) and everything to do with slip. Or, more correctly, LACK of slip. A clutch with extremely grabby material will slip less than one with more forgiving material. My frustrations with the old street drag was that it allowed almost no slip from a stop. So, knowing that the pressure plate is moving at exactly the same speed, and the clutches, and the flywheel, and the floater plate, regardless of whether it is a single disk clutch or a dual disk, all move at the same damn speed.. How can material change how fast a clutch shifts? It will grab SOONER. When you pop the pressure plate, and it slams against the clutches, they will grab sooner on the floater plate, pressure plate, and flywheel. If we have 2 different materials, A and B. A slips for 2” on the flywheel. B slips for 3”. A is a faster shifting material. Does that end the debate? Unfortunately, not really…

Well damn it, why not? I just said that A shifts faster than B.. That should be the end of the story… and maybe it is. Maybe there are folks out there that are so concerned with 10ths of hundredths of seconds that they will just end the debate there and move on. Professional drag racers (or bench racers). But the truth is, we have friction in another area that can demonstrate if the clutch is catching soon enough.. Tires. If you are breaking traction between shifts (or chirping), the clutch is catching soon enough and with enough force that friction is now lost between the tires and ground… So lets be perfectly honest with ourselves.. How much difference is there in shift times?

Once again, we are NOT talking about how long it took to change gears.. We are only talking about the difference in time between when you released the clutch (pressure plate) to when it fully seated and stopped slipping. So, is an aggressive dual disk that catches within 3” slower shifting than a soft material single disk that catches in 5”? Nope. So, does the fact that the clutch is a dual disk make it take longer to shift? No. The factor is MATERIAL, not the amount of disks in the clutch, and it has nothing to do with how quick you change gears.

Can we make a blanket statement of “dual disk clutches shift slower than single disk clutches?” Absolutely not. We can only say that depending on the material used in the clutch, shift speeds may very, REGARDLESS of whether is it a single disk of dual disk. How much? Fractions, fractions of a second. Going even further than that, we generally WANT a little slip between gears for various reasons.. An entire thread, all together.

That leaves us with 1, single, final variable that could make a dual disk shift slower than a single.

Weight.

Where is the weight increased? On the engine side, the flywheel weight is increased (by bolting a floater plate to it, or allowing it to ride in grooves on the flywheel). On the transmission side, the clutch weight is increased (by adding an entire additional clutch).

Could this finally be what causes the transmission to shift slower? At face value, the answer seems to be “yes.” Why? Pretty simple: you are putting additional load on the transmission synchros by adding weight. (You could, in theory, also make it more difficult for the engine to reduce engine speed due to the increased weight in the flywheel, which could make it more difficult to match engine speed to gear ratio in your shifting. I’m not going to bother with the math involved in that theory, but I’m willing to bet it is minimal at best.. Much like I’ll show the additional clutch is minimal, at best.)

Lets start with how additional weight could cause the transmission to shift slower (at least in theory).

Since your foot is moving at the same speed, the hydraulics are moving at the same speed, and clutch material doesn’t become a factor until you are in gear and releasing the pressure plate against the clutch… The only other factor of how a dual disk clutch could shift slower is if you are unable to move your hand into the next gear at the same speed. That is the true “shifting speed.”

I wanted to do this with the nv5600, but I can’t find a gas engine application. So I’m going to use the nv4500 instead.

Assuming you can move your hand at the same speed before you installed the manual transmission, the only factor in gear selection speed should be if the synchros can handle the additional weight and allow you to change gears at the same speed as before. They are functioning in the exact same way, but are required to do more work with the added weight.

So, if the synchros are capable of handling the increased work load, they will function in the same way, correct? Much like if you push 2.5 pounds at exactly the same speed as 2 pounds, you are not moving any quicker or slower.

How do we know if they are capable of handling the additional weight? Measure the centrifugal force, compare how much additional force the second clutch adds, and see if there is a real life example of the synchros managing more force than what the additional clutch generates.

Check out this handy calculator to show exactly what I’m talking about:

CalcTool: Centrifugal force calculator

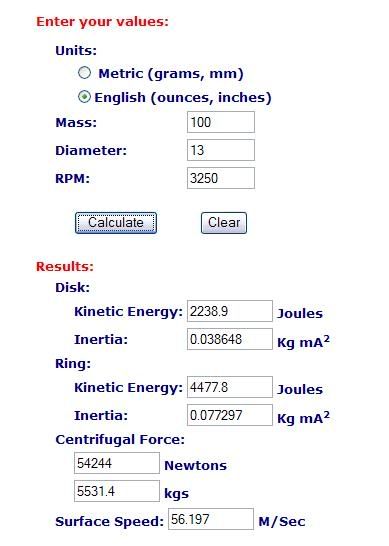

We are using made-up numbers since I do not have the exact numbers available.. It makes little difference in the demonstration though. Watch:

13” radius (approx size of clutch), Speed 3200 rpm (engine/transmission speed), weight 5 pounds (approx the weight of a clutch disk) = 18905.3 lbf.

These are not exact numbers, but they don’t need to be for the demonstration here. You’re clutch is exerting18905.4 lbf at 3200rpm.. Or, when many are shifting. That means that the synchros need to deal with 18905.4 lbf in stock form. Can they handle that? Yes.

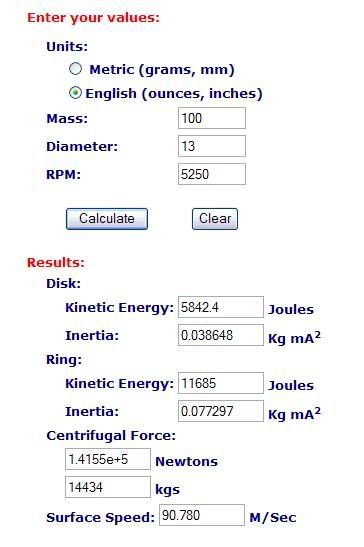

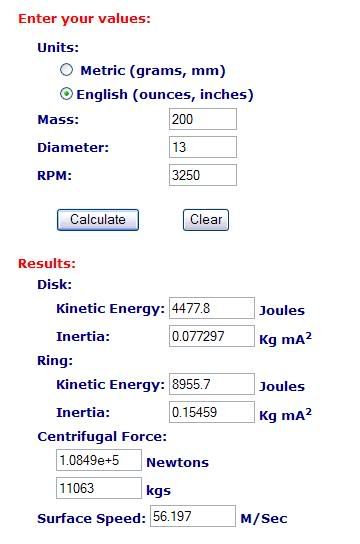

Lets double the weight, just like a dual disk clutch: 13” radius, 3200 rpm, 10 pounds weight = 37810.6. Pretty darn significant change, right? Well.. Lets think about this for a moment.

The NV4500 has many gas engine applications. Same transmission, but 1 huge difference.. RPM baby!

Lets plug all of our numbers in for a GAS engine this time.

13” radius, 5200 rpm, 5 pounds weight… …. …. …. … = 50886.5 lbf.

Whoa doggy! Big difference.

Think the engineers thought this one over when they designed the transmission? You bet your sweet ass they did. The synchros aren’t even breaking a sweat at our RPM levels, even with a big, heavy, dual disk clutch. The biggest issue you may encounter by going with a dual disk clutch is increased bearing and synchro wear from the increase in weight. However, the synchros are more than capable of handling those loads… They were engineered to do so from the factory!

So what is the only plausible explanation for a dual disk clutch “shifting slower” than a single?

It’s called the Placebo Effect, and only us diesel heads seem to experience it.

I’ve got tough skin, so all you nay sayers, let’s hear why I’m wrong. :Cheer: :Cheer: