What's the main reason these plugs go? RPM? Water Pressure? Boost? Cyl pressure lifting the head?

This is a post from another forum Shane @ Wicked did to explain it.

Regardless of anything else, what happens when cast iron heats up, it expands. What happens to coolant as it heats up it expands. What happens when you add more fuel and air, it expands further. The backed up pressure (coolant that does move through the system very well), combined with the heat is what pops the plugs out. Can a stock truck blow the plug out, yes. Can a modified truck blow a plug out easier, yes.

The more power you add, the more difficult it becomes for the factory coolant system to be able adequately transfer the heat out of the system via radiation.

What we are dealing with are several things contributing to the issues we see. No one thing is to blame.

It might be hard to wrap your mind around this, there are 2 different things happening in the coolant system. The coolant is expanding as heat is transferred into it, therefore we use a radiator cap to raise the boiling point and for containment purposes. The other side is the water pump, its job is to transfer the coolant through the engine and through the radiator. The flow rate as determined by the engineers provides the necessary transfer rate for the heat to be dissipated through the radiator. If the coolant can't circulate properly in an area of the engine, it keeps getting hotter and surrounding metals expand to higher rate. Now double the horsepower output, or triple it, more heat. So as stated earlier, there are several contributing factors for blown expansion plugs, last of which is a casting hole that is machined a little to large to begin with.

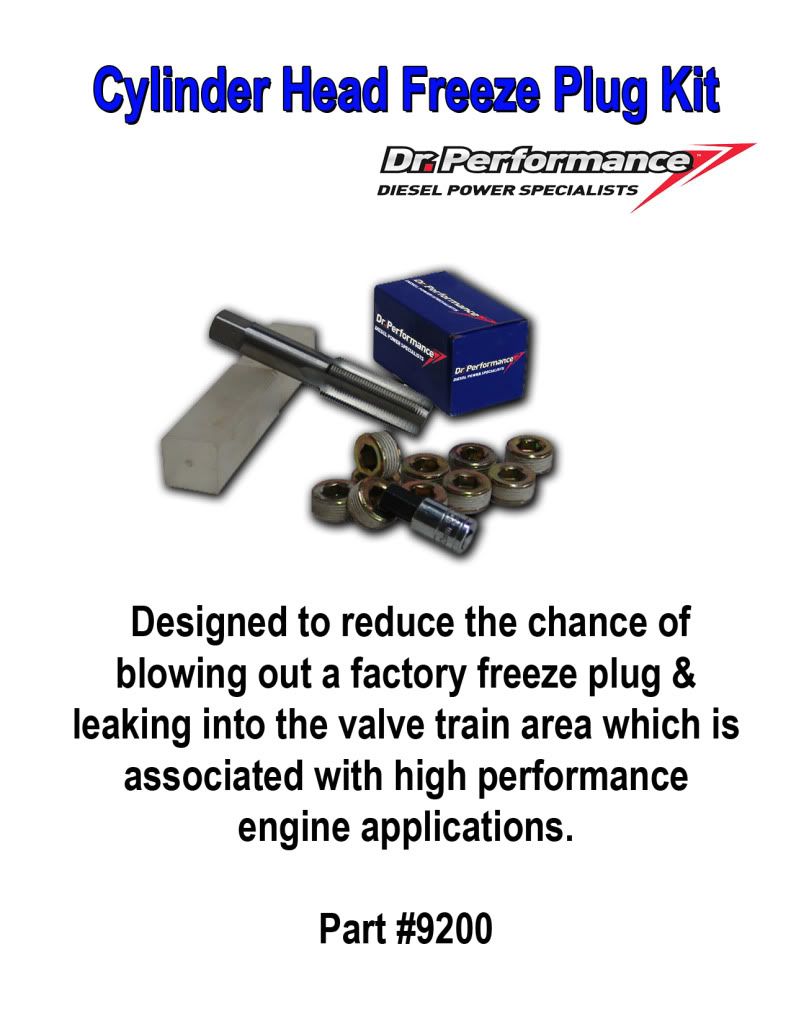

For all the things that contribute to blown plugs, a remedy is to provide an escape path for restricted flow, poorly circulating coolant, high pressure, or very hot coolant that isn't cooling anything anyway, robbing power from your engine trying to push out the plugs and kill your engine making you have to get a ride home.