getblown5.9

Ceritified Kleenex Dealer

- Joined

- Aug 3, 2006

- Messages

- 7,259

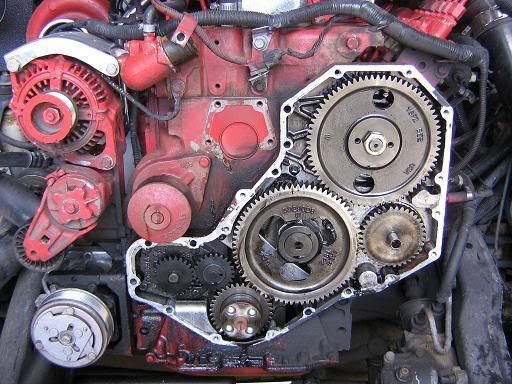

I read the thread the other day where highfinance had a cam gear break after he had heated it to press it on/off etc. Everyne said heating the gear is bad because it weakens it and I'll agree. I assume most people were doing this with a torch of some kind and applying heat from the outside.

What if you were to use a bearing induction heater? This is a more controlled heat and heats the metal equally. The guy helping me press my cam gear off and on did it once before on another persons cam using the induction heater because it makes the job alot easier vs. just trying to use excessive force to press the gear off.

What if you were to use a bearing induction heater? This is a more controlled heat and heats the metal equally. The guy helping me press my cam gear off and on did it once before on another persons cam using the induction heater because it makes the job alot easier vs. just trying to use excessive force to press the gear off.