You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Help cutting front coils

- Thread starter bateman

- Start date

bateman

Active member

Driveline shop that I’ve never had anything but issues with of course sucked again. Rocket City Off-road needs to stick with front end lifts on the bro dozers. Driveshaft has 6 giant ass weights on it compared to the one dime sized factory weight. Knew it was going to suck and it indeed does suck.

Going to pull some measurements and try to find a used factory shaft to buy.

Going to pull some measurements and try to find a used factory shaft to buy.

thatguy69

New member

Driveline shop that I’ve never had anything but issues with of course sucked again. Rocket City Off-road needs to stick with front end lifts on the bro dozers. Driveshaft has 6 giant ass weights on it compared to the one dime sized factory weight. Knew it was going to suck and it indeed does suck.

Going to pull some measurements and try to find a used factory shaft to buy.

My buddy was just complaining how the colder weather really extends his cooking time on his pellet smoker. And that does suck, I go to an old guy an hour north of me for driveshafts and he does great work and cheaper than dirt. Not sure what I'm going to do when he decides to give it up.

bateman

Active member

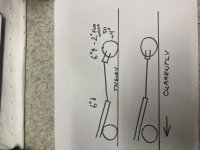

After some more time laying under the truck staring at shit I’ve come to the conclusion my driveshaft angles are not appropriate. Driveshaft angle out of the tcase is slightly up. Pinion does not match (equal but opposite angle).

Now I’m confused. Reading that 2wd axles are different from 4wd. Shock mount angles and apparently pinion angles although I can’t find a clear answer. Frustrating how little info is out there for these trucks on various topics when compared to other platforms I’ve played with.

Shocks looks like they got 2” of travel before bottoming out. Not a problem yet but not optimum. $300 for shocks that I’ll likely be replacing. I do not want the shocks to be the bump stop when I finally hit a dip or pot hole.

Current plan is to find a 2wd truck and lay under it and look at a few things. Hopefully I can get these bugs worked out fairly easily.

Now I’m confused. Reading that 2wd axles are different from 4wd. Shock mount angles and apparently pinion angles although I can’t find a clear answer. Frustrating how little info is out there for these trucks on various topics when compared to other platforms I’ve played with.

Shocks looks like they got 2” of travel before bottoming out. Not a problem yet but not optimum. $300 for shocks that I’ll likely be replacing. I do not want the shocks to be the bump stop when I finally hit a dip or pot hole.

Current plan is to find a 2wd truck and lay under it and look at a few things. Hopefully I can get these bugs worked out fairly easily.

That wont work well at all with caltracs, gotta have the pinion negative.

Also remember caltracs under a load working as they should will lift/seperate the rear end. So dont try to get your angles dead on matched just sitting.

I've been running caltracs a good while, not just talking out my ass.

Also remember caltracs under a load working as they should will lift/seperate the rear end. So dont try to get your angles dead on matched just sitting.

I've been running caltracs a good while, not just talking out my ass.

bateman

Active member

Thanks for the help Jason.

I know you know your shit so hope I didn’t come off wrong way. Just making sure I was making sense.

Going to dig around and see if I can find some info from 2wd guys. Should be same ride height but length of a t case might make the difference. Shit I hope I don’t have to Jack this thing back up what a waste of time and money.

I know you know your shit so hope I didn’t come off wrong way. Just making sure I was making sense.

Going to dig around and see if I can find some info from 2wd guys. Should be same ride height but length of a t case might make the difference. Shit I hope I don’t have to Jack this thing back up what a waste of time and money.

bateman

Active member

Well the trans mount is definitely shot.

Angles are a bit off but it is nothing crazy. I’m going to try my buddy’s driveshaft and see if anything changes. All the threads on here of people doing exactly what I did and I haven’t seen any mention of angle probs. Unless the perches are welded different it should be exactly like a 2wd Is setup.

Angles are a bit off but it is nothing crazy. I’m going to try my buddy’s driveshaft and see if anything changes. All the threads on here of people doing exactly what I did and I haven’t seen any mention of angle probs. Unless the perches are welded different it should be exactly like a 2wd Is setup.

Attachments

bateman

Active member

Yea my buddy left the keys to his truck for me so maybe I can run out in the morning and give it a shot.

The yoke phasing seems right on my shaft so maybe I was right with my first ASSumption that the place that did the shaft just didn’t balance it well. I just really don’t see these angles causing such a vibe but I’m no expert.

Trans mount will be ordered as soon as I pick one.

The yoke phasing seems right on my shaft so maybe I was right with my first ASSumption that the place that did the shaft just didn’t balance it well. I just really don’t see these angles causing such a vibe but I’m no expert.

Trans mount will be ordered as soon as I pick one.