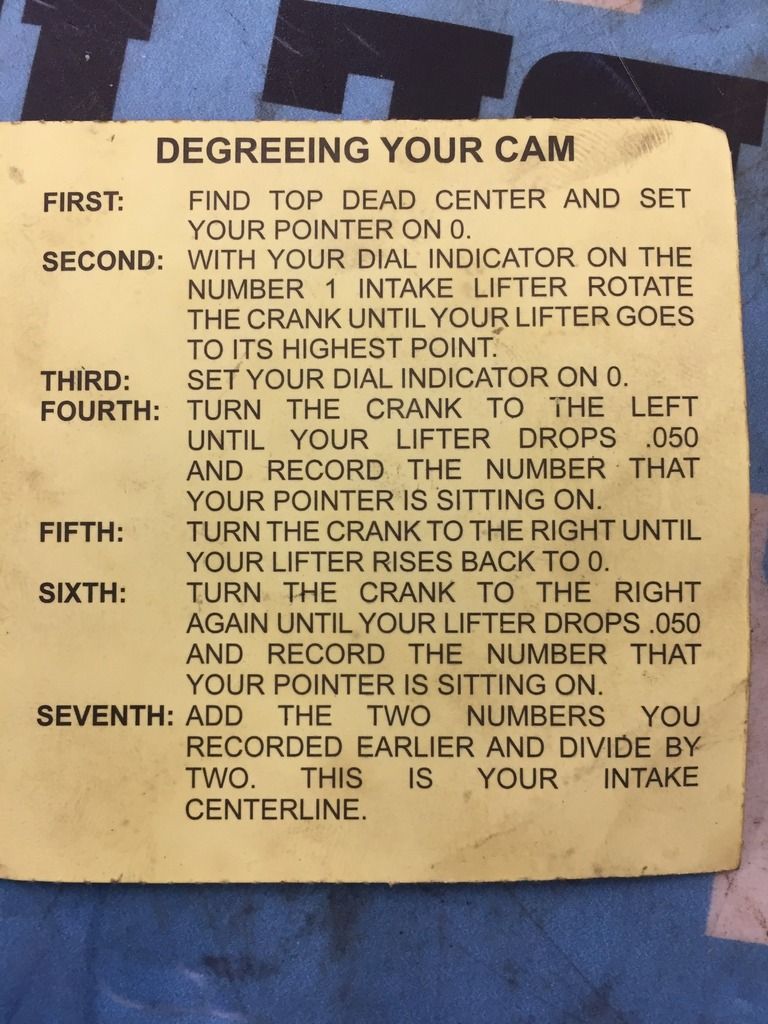

Is there anyone in the Cincinnati area who has experience degreeing a camshaft who would be willing to stop by and assist me with my upcoming cam install? I've read quite a few write-ups and watched a few videos on the topic, but would still feel more comfortable if someone with experience was there to walk me through it for my first time.

I need to make a couple phone calls first, but I'm planning on running a 194/220 cam and, because the tolerances are so tight, I'd prefer to have some expertise on sight to assist.

I'd be willing to buy dinner, beer, or pay someone if I need to.

I need to make a couple phone calls first, but I'm planning on running a 194/220 cam and, because the tolerances are so tight, I'd prefer to have some expertise on sight to assist.

I'd be willing to buy dinner, beer, or pay someone if I need to.