m880cummins

New member

- Joined

- Apr 29, 2013

- Messages

- 142

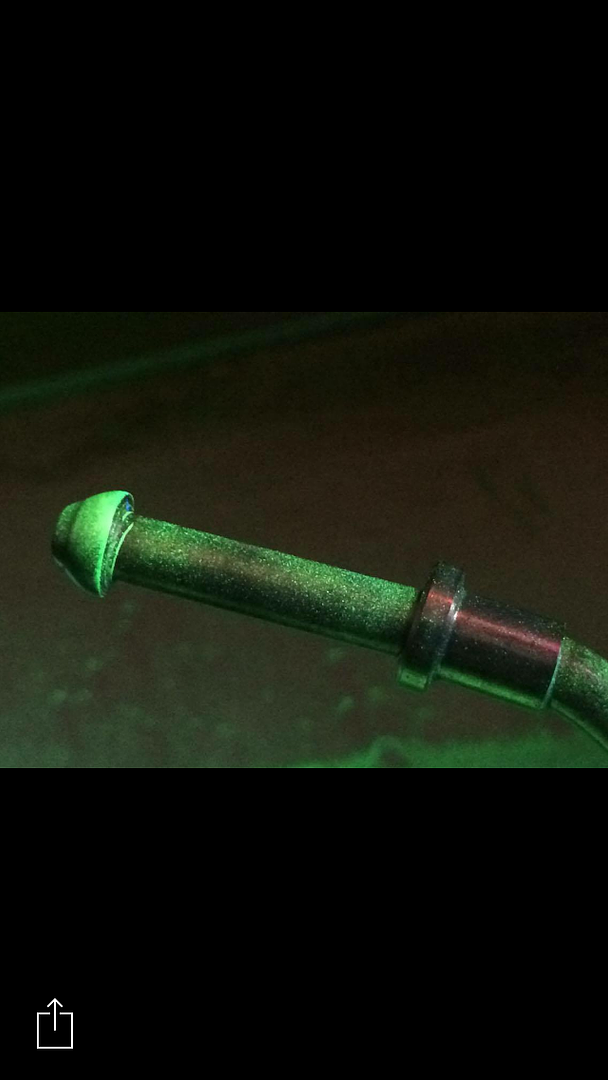

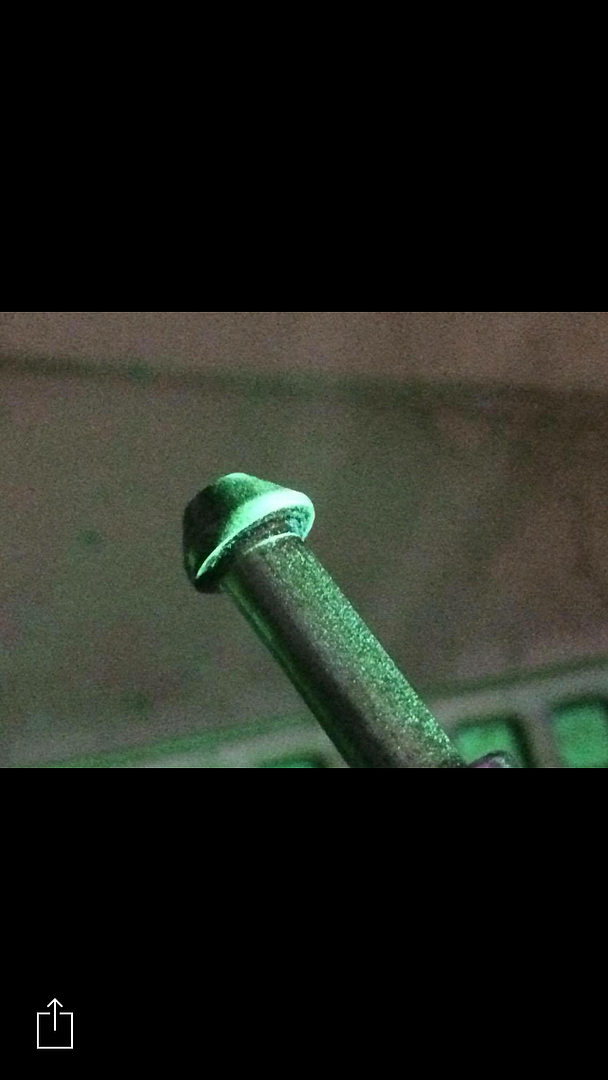

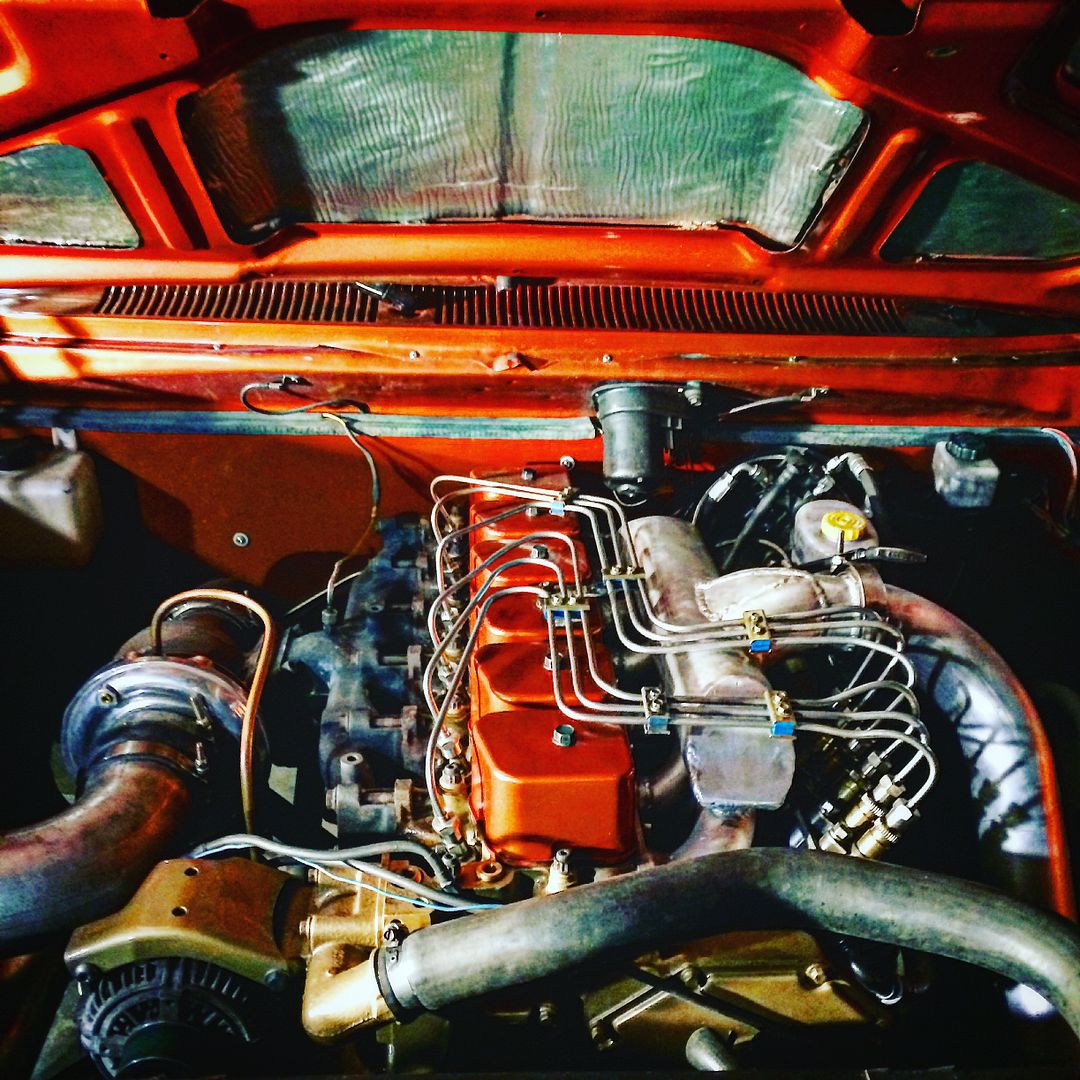

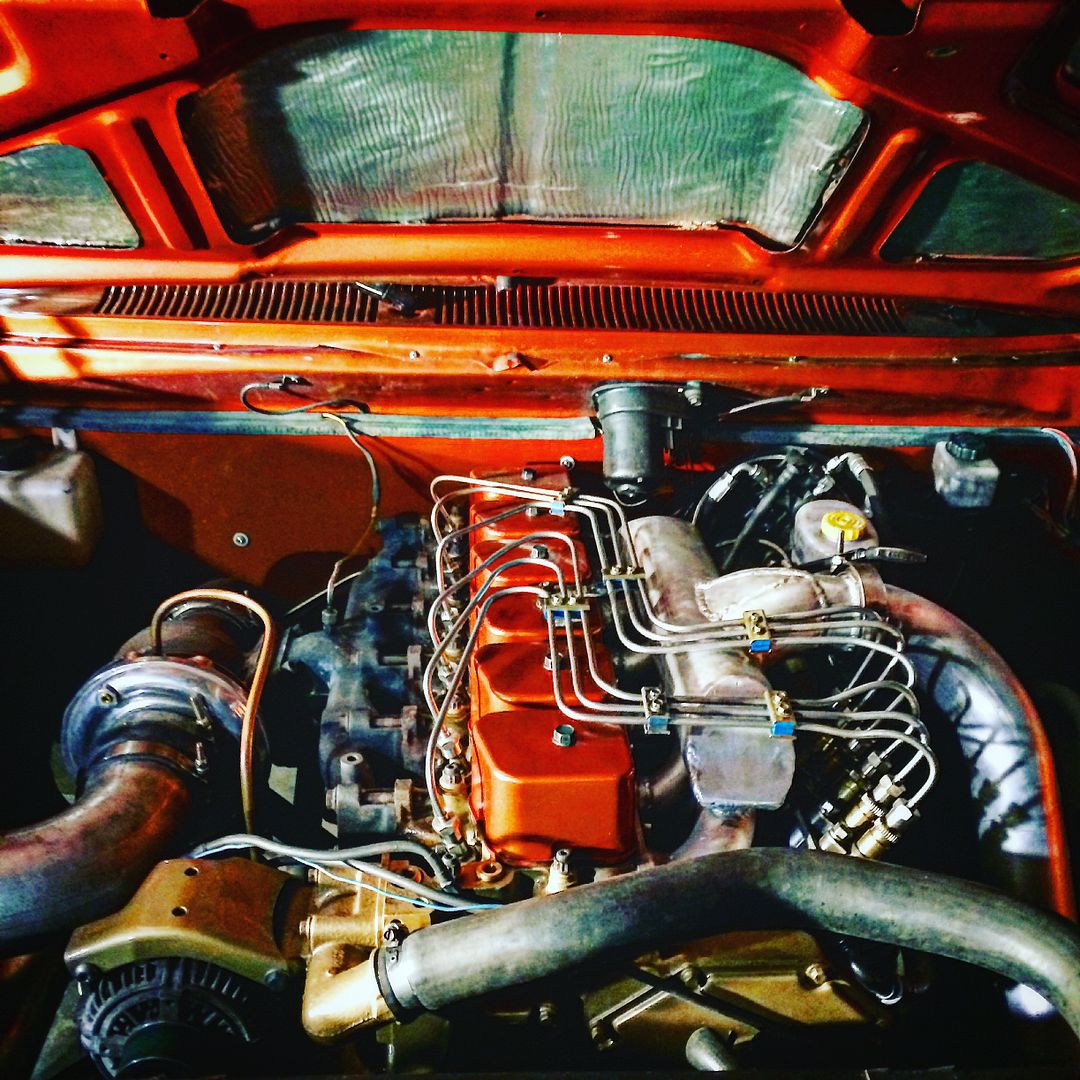

So I built this 12v this spring and did my own intake and bent my own lines. Lines were from columbus. I bought 7 originally (1 as a spare) and in the 14000 miles I have put on the truck, it just broke a 4th line tonight. The lines run me $60 each and every time, they have cracked right between the collar and the flare. Can't even really see the crack but it is there. Going to magnaflux them friday to get pics. I'm just fed up with this. Plenty of clamps, no sharp bends and the lines sit properly before being torqued and clamped. Could it be poor quality? They are mild steel .084 36" long lines.

Thanks for any help in advance.

Charlie

Thanks for any help in advance.

Charlie